By 2025, it is projected that there will be more than 50 billion devices connected to the internet. This is having a disruptive effect on many industries, including transportation, financial services, and the media, among others. The oil-and-gas sector in Newfoundland and Labrador is also experiencing significant changes as a result of digital computing technologies.

Disruptive technologies of digitalization are changing traditional business models and giving rise to the digital economy. They are changing how entire businesses operate and the way people live and work.

In the retail sector, for example, it has allowed customers to place online orders and retailers to then analyze customer data for personalized advertising and services.

Canada’s offshore energy industry has vast potential for growth. A major oil-producing field called Hebron was started last year in offshore Newfoundland.

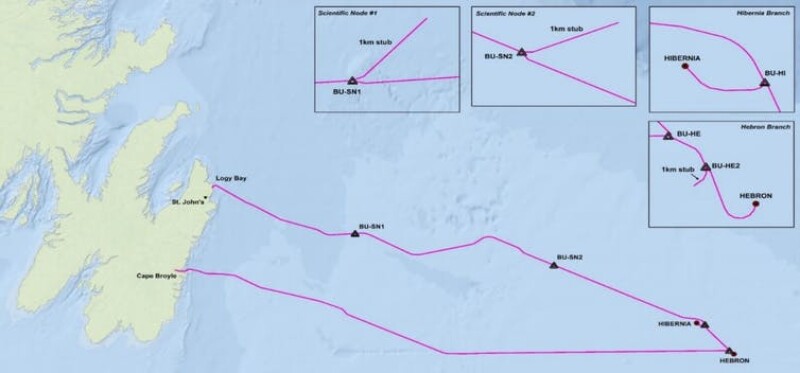

Newfoundland and Labrador is currently producing about 25% of Canada’s conventional light crude oil. Through a recent Grand Banks Offshore Optical Cable, new fiber-optic telecommunications links with offshore fields will have a dramatic effect on future business operations.

From Digital to Intelligent Oil Fields

A digital oilfield is a complex information system for a petroleum reservoir. It connects all components, including offshore facilities, databases, control systems, and management networks. The development and operations of offshore oilfields can be greatly enhanced by digital technologies, because they allow companies to collect more information about the reservoirs and improve business decisions.

After a digital oilfield is initially constructed, digitalization can progress from early stages of real-time data analysis to more mature advanced stages of integrated operations that link operational, business, and computer systems together.

This will optimize production and ultimately lead to intelligent systems that use expert experience for automated decision-making.

As Wuhan University professor Li Deren writes, oilfield digitalization allows an engineer to “know about everything under the heavens,” whereas oilfield intelligence allows them to “do everything under the heavens.”

Companies such as Equinor are using digital technologies to help improve the safety of personnel, security, and efficiency of offshore operations. The digitalized offshore assets will have a higher reliability of operations. Predictive and automated maintenance will reduce costs.

The digital economy will also lead to a more environmentally responsible development of offshore oil resources. Through integrated environmental monitoring, digital ocean facilities will reduce the environmental impact and risks of oil spills. Subsea (fully submerged) wireless communications will have access to control systems and sensors that monitor pollutants.

Digitalization and the Labor Market

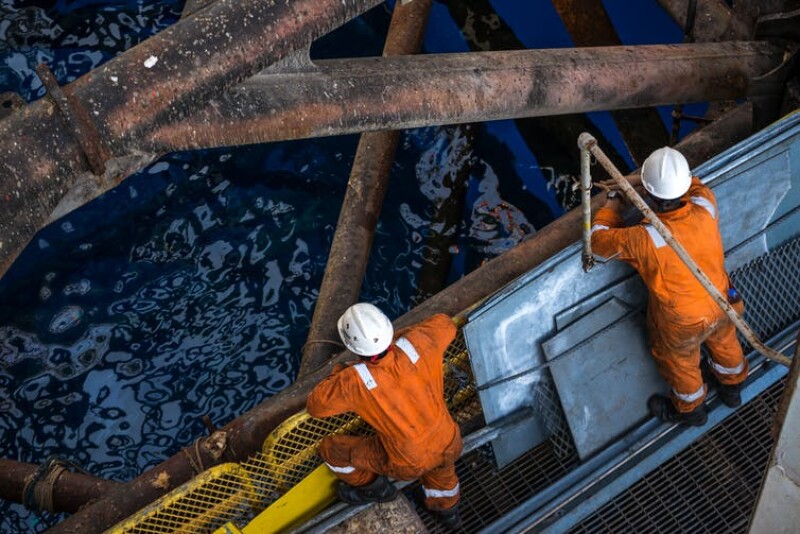

Some offshore jobs, often in harsh ocean working conditions, can be moved onshore, thus improving safety.

3D rendering of a subsea cable.

As the entire offshore enterprise becomes digitalized, tools such as data analytics, artificial intelligence, and cognitive computing will optimize the overall operations and personnel safety. Increasingly, more offshore activities will become automated, from drilling to production, maintenance and operations. Operating costs will decrease as more processes become digital and equipment use is optimized.

But these changes will also bring challenges in the labor market. Jobs that do not require creativity, social skills, or human dexterity may disappear. A McKinsey study estimated that digitalization changes for both technical and nontechnical work may automate 60 to 90% of routine manual tasks in the traditional job activities.

What does this mean for the job market in Canada’s offshore sector? Jobs on offshore platforms that consist of repetitive activities may decrease, but new types of onshore jobs will be created. New job titles will appear such as data analyst, cybersecurity specialist, and robotics and artificial intelligence engineers, to name just a few.

The role of higher education in training workers will become ever more important. There will be an increasing need for some competence in information technology in jobs that did not previously require it.

Jobs that consist of repetitive functions will become automated.

Innovation and Education at Memorial

At Memorial University, the Faculty of Engineering and Applied Science is responding to these challenges through innovative programs and research.

Lesley James, a process engineering professor and director of the Hibernia Enhanced Oil Recovery Laboratory, is using digital oilfield technologies to reduce costs and increase production by enhanced oil recovery. James and her team recently launched a new model of digital oilfield education, which provides a flexible modular approach via short courses in the classroom and by distance learning.

The digital oilfield modules include automation, machine learning, communications, artificial intelligence, and instrumentation. Relevant case studies are applied to offshore applications.

Memorial’s researchers are also developing leading-edge technologies for ocean digitalization. Connectivity between cabled and acoustical seafloor sensors, autonomous underwater vehicles, and surface stations require advanced communication and processing units. Octavia Dobre, an electrical engineering professor, has developed new methods that increase the throughput of underwater communications and enable longer-distance, more energy-efficient methods of transmission.

The Grand Banks offshore optical cable connects Newfoundland’s offshore and onshore oil field operations.

Greg Naterer, Dean and Professor, Faculty of Engineering and Applied Science, Memorial University of Newfoundland.

This article is republished from The Conversation under a Creative Commons license. Read the original article here.