The focus in unconventional exploration and production is shifting to maximizing production. “The next big play is getting more out of what you have,” said Jay Ottoson, president and chief operating officer for SM Energy, at the recent Unconventional Resources Technology Conference in Denver.

The math is simple. Adding one percentage point to recoveries from the top unconventional formations for oil and gas in the United States will add billions of billions of barrels of oil production and tens of trillions of cubic feet of gas, he said.

There is plenty of room for improvement. The examples offered by Ottoson would increase the ultimate recovery rate in the biggest US oil plays from 5% to 6%. Comments by others during the conference, a joint project of SPE, AAPG, and SEG, indicated that range is not uncommon as companies look for ways to do better.

Even at those levels, the growing flow of oil and gas from these extensive formations has pushed the US up toward the top of the list of the world’s producers. Scott Key, chief executive officer of IHS, said that in a few years, the United States will again emerge as the world’s largest producer of oil and gas.

The production increase has been enough to boost the growth rate of the US economy, turning it into the low-cost producer in refining and chemical making and soon an exporter of liquefied natural gas, Key said.

Rick Bott Jr., president and chief operating officer of Continental Resources, described the company’s ap-proach as “we have a simple sort of strategy, we drill a lot of horizontal wells.” Anadarko is drilling about one well a day in the Wattenburg field in Colorado, said Brad Holly, vice president for the Rockies at Anadarko Petroleum.

While the pace is steady, methods are constantly changing. Improvement is in the details. To begin with, the particulars include more precise drilling of clusters of wells that are spaced and fractured based on a growing understanding of how best to efficiently drain a formation.

Continental, which was a pioneer in the Bakken in North Dakota, and SM reported pilot projects on what Bott called “down spacing,” that is, seeking gains by drilling wells on a single pad site to varying depths. “The technology is changing monthly,” he said.

Coming are projects to enhance the output of older wells, such as installing downhole pumps and refracturing older wells. “We have not really started working on production enhancements,” Bott said.

Anadarko is drilling horizontal wells to revive a formation where new wells must be carefully drilled around many old ones. “We are operating among 17,000 vertical wells. We need to minimize interference with existing wells that are as little as 15 ft away,” Holly said.

Products displayed at the conference helped define the challenges of this sort of development. They promised information that could be used to make better development decisions, deliver it fast enough to keep up with rapid field work, and at a price that is in line with price-conscious mass production operations.

Unconventional exploration and production is a bit like farming, said Don Westacott, chief adviser for global unconventional reservoirs at Halliburton, who grew up on a farm in western Canada. Both can be profitable enterprises, but they require expensive inputs, the cooperation of nature, skill, and persistence.

And both farmers and oil companies can be so productive that they glut the market, driving down prices.

Schlumberger offered a reminder of the challenges of this business during a display at its booth. At the bottom of the screen during a video on its TelePacer drilling platform, which is designed to help drillers drill wells according to plan, was a constant reminder that 40% of wells are subeconomic and 35% of all fracture stages do not contribute.

Multiple Measures

The measures of success go well beyond reaching a threshold profit margin. Intensive development with many wells fractured using millions of gallons of water and sand make landowner and government relations a critical skill. The industry’s ability to reduce the footprint of operations and deliver consistent results will be judged as it tries to export unconventional development to countries where the costs, culture, and land use rules may be obstacles to development.

“The technology issues will be handled,” said Robert Ryan Jr., vice president of global exploration for Chevron. Just as important, companies need to manage projects with interdisciplinary teams that include and value input from experts in the environment, government, and public relations.

The conference was held in Colorado where operators have agreed to a plan with regulators on a goal to eliminate methane emissions. The first step, now in progress, is to develop methods to measure leaks as natural gas travels from the wellhead to market, and surveys to target leaks from the air and the ground.

Anadarko is working to reduce the size of its drilling pads by 40% by using pipelines to allow some functions to be moved off site, Holly said.

The pace of unconventional development is also likely to depend on a decision by the US government about exports of oil. A ban dating back to the 1970s is limiting exports of the ultralight liquids flowing from unconventional fields, much of which could be described as natural gas liquids.

Light crude demand is limited by the fact that US refiners adapted to falling domestic production by setting up their operations to refine heavy crude, which is normally the lowest-cost grade. Now, the ultralight crude from unconventional wells is selling at a discount because the growing supply is a poor match for what domestic refineries are set up to handle.

Multiple speakers at the conference cited a recent IHS report predicting that price discounts on light US crude due to the export ban would slow US unconventional growth. IHS’ recommended solution to the problem would require two political feats in Washington: an end to the export ban so US light oil could be sold on international markets at a higher price, and government approval of the Keystone Pipeline, which could deliver heavy crude from Canada to replace it.

“We need free trade,” with exports of US oil, said Key of IHS. “Without it, we will see stagnation.”

Mining Water for Data on Unconventional Reservoirs

After millions of gallons of water are pumped into a well to hydraulically fracture the rock, it is commonly thought that the water produced in the days afterward is the water injected for fracturing. But a study by Pioneer Natural Resources suggests that most of the water produced is flowing up from the formation, not flowing back from fracturing.

When it chemically analyzed the water from a fractured well in the Permian Basin near Midland, Texas, Pioneer found that “what we are producing is dominated by formation water, not fracturing water,” said Matthew Laughland, petroleum geochemist at Pioneer, who delivered the paper (URTeC 1926712) at the recent Unconventional Resources Technology Conference in Denver.

In wells that have been monitored in the months since they were completed, the formation remains the dominant source of the water, most of the time.

“Water produced at the surface within hours, days, and weeks of a well being brought on production is predominantly formation water, in some cases as much as 100% formation water that is punctuated by episodic mixing with frac water,” which occurs during certain weeks at unpredictable intervals, the paper said.

The petroleum geochemist did a series of tests showing that water from wells can offer insights into what is going on below. While the chemical makeup of oil has been frequently studied to better understand the subsurface geology, he said “there has been little attention to the chemistry of produced water.”

Distinguishing injected water from formation water is difficult, because what flows out of the well will carry salts and minerals from the formation, regardless of its source. But Laughland found certain distinctive isotopes and ions in injected water that significantly differ from the ones in formation water. There are also differences in water found at different depths and locations in the reservoir. “There is a distinctly different signature for frac water and produced water,” he said.

Pioneer’s water analysis began with a study of two wells producing large amounts of water. Chemical markers in the water indicated the horizontal wells drilled at different depths intersected with a large fault. Certain ions and isotopes found in the water from the two wells were nearly identical and distinct from the fingerprint of water from nearby wells beyond the fracture.

Another study found that the water from producing zones at different depths in the Wolfcamp formation had different signatures. That observation proved useful when investigating whether a fracture in one zone extended into a second one separated by a couple of hundred feet. While microseismic testing suggested the completion was draining two zones, the chemistry of the water indicated it all came from one zone, Laughland said.

This new area of study raises questions that remain to be answered. One explanation offered for why formation water dominates over flowback of fracture water is that the fractures opened to produce oil and gas could also release water from the clay-rich formation, which is prone to absorbing fluid. The water injected into the formation, however, is less likely to return because it was pushed into low-permeability fractures.

One theory that Laughland rejects is the possibility that the markers used to identify frac water can be altered in the formation. For the tests to mistakenly classify fracturing water as formation water in the hours after the job, major chemical changes would need to quickly occur, including an exchange of oxygen and hydrogen isotopes by means of diffusion or dissociation. The paper said that was “highly improbable.”

North Dakota Gas Flaring Inspires Enhanced Oil Recovery Thinking

The amount of natural gas flared in North Dakota keeps rising with the rapid growth of oil production, even as the percentage flared slowly sinks.

The fact that the gas burned has risen from 80 Bcf in 2012 got professor Todd Hoffman thinking, and talking to colleagues at the Colorado School of Mines about alternatives to a practice with multiple downsides, the most obvious being that it is a waste of a valuable resource.

“I am the kind of person who will use a sliver of soap until it wears out. I do not want to waste things,” said Hoffman, who is moving to Montana Tech, where he will continue to be a petroleum engineering professor.

North Dakota has taken action this year to push operators to do more to reduce flaring, but the amount of gas flared is expected to remain high because the capacity of gathering systems and pipelines is lagging the supply of gas from the state’s Bakken formation.

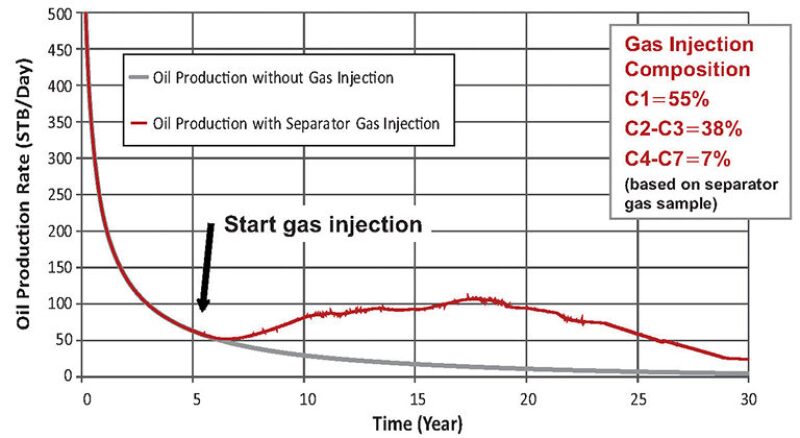

Hoffman, who took an early interest in enhanced oil recovery (EOR) in the Bakken, proposed reducing the flaring by reinjecting the gas, which could increase long-term oil production, during a presentation at the recent Unconventional Resources Technology Conference in Denver.

The paper makes a case for gas injection as a profitable alternative to waiting for pipelines to be built. That is likely to be a slow process because there is a large national backlog of work to be done and the low price of natural gas makes these lines less attractive to build. In the meantime, the possible methods could include a slowdown in development that would threaten the growth projections of publicly traded oil producers.

Gas injections have been used in conventional formations to extract more oil, and Hoffman said the same could be done in unconventional formations.

The ethane-rich gas found in the Bakken could be as effective as carbon dioxide in increasing oil recovery. Both gases become miscible at similar pressure levels, which is necessary in many formations to ensure the maximum effectiveness. The paper projects natural gas EOR could be done profitability, with an annual rate of return ranging from 13% to 22%, depending on assumptions about costs and the value of the hydrocarbons sold.

The simulation indicated that gas injection could double the ultimate recovery rate of oil in the formation, the paper said.

But this is an idea, not a proven concept. The skeptical questioning following the talk focused on whether it would be possible to inject enough natural gas into rock so tight that it was long thought to be impossible to commercially remove natural gas that the industry knew was inside.

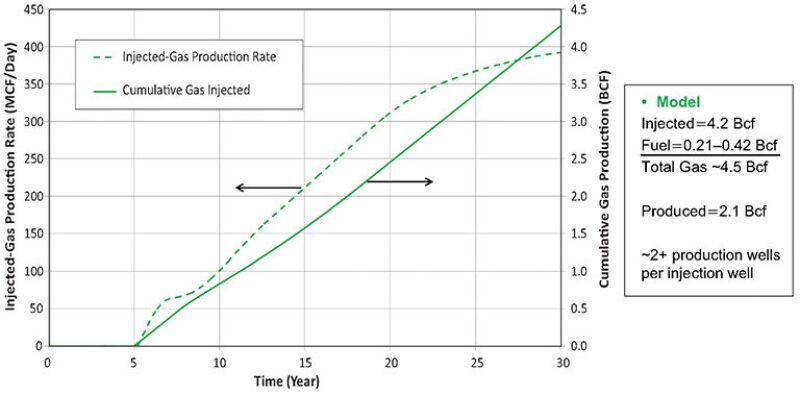

Hoffman answered, “the answer is clearly yes.” Based on the response from two Bakken operators, he said it was possible to inject 1 MMcf/D.

He envisions converting old producing wells into injection wells, with one injector for every two producers.

When it comes to pushing water through the formation, the answer is not so clear. Hoffman’s plan calls for alternating injections of water and gas to reduce the amount of gas breaking through the liquid to the producing well. Breakthrough reduces the gas’ ability to sweep out oil and increases the natural gas in the production stream.

Simulations showed that only about 5 B/D of water could be injected before the pressure required to inject more was likely to fracture the rock. While Hoffman said that seemed low—and plans coreflooding experiments to gather better data—he adjusted his plan to limit the amount of water injected to a short period lasting as long as the formation was accepting the water, before a switch back to gas.

Answering the questions will require more laboratory and field work to see what the risks and rewards are. Hoffman is hoping to find an operator willing to do a pilot test, which could offer a more convincing argument than lab work and computer simulations. Experience has shown natural gas injection systems can be an effective way to increase production from conventional reservoirs and make use of stranded gas. But engineering, building, and operating systems to do the work is a large, long-term investment.

“A not-so-unconventional idea” offered by one engineer after the talk was to inject gas into old conventional fields in North Dakota, which often lie above the source rocks that are the exploration target now in the Bakken.

The idea was offered by Shaun Hoolahan, a Montana consultant who worked on gas injection systems on the North Slope of Alaska, when he was with Arco. He said the approach would eliminate questions about whether “jamming it into the reservoir is a problem.”

Hoffman offered presentations at the beginning and the end of a session at the conference, which showed the growing interest among universities in unconventional EOR. One made a case for using natural gas, rather than carbon dioxide, which is being considered as an unconventional EOR option as well.

Simulations by New Mexico Tech show that using carbon dioxide in this extremely tight rock would strip away lighter hydrocarbons, leaving behind denser crude that is less mobile. It concluded that natural gas injection could produce more oil because it would not have that effect, said Vanessa A. Fai-Yengo, a graduate student at New Mexico Tech.

Natural gas offers some easier-to-prove advantages over carbon dioxide; it does not require corrosion-resistant hardware and it is readily available in the Bakken, while carbon dioxide is not. And the injected natural gas can be produced later, when it may command a better price.

International Shale Development: Daunting Barriers vs. Overwhelming Needs

There is a world of rocks out there offering unconventional oil and gas opportunities, but for those used to the pace of development in the United States, progress may seem to be operating in geologic time.

“The progress is very, very slow,” said Mark Ian Smithard, business development manager of unconventional development in Africa and Latin America at Chevron, during a panel discussion on international development at the recent Unconventional Resources Technology Conference in Denver.

The roadblocks to development differ from country to country. Still, the combination of rich resources available and the pressing need for greater production, particularly of natural gas, makes development seem inevitable.

“The requirement to develop gas and deliver it economically will set the pace for use,” said Brian Gratto, manager of unconventional resource exploration and development at Saudi Aramco. In a country with growing energy demand, “we want a source of gas to offset oil burned to free up liquids to be exported,” he said.

But the pace is dictated by a systematic development of the below-ground resources and the above-ground infrastructure needed to build an unconventional resource business from scratch. Saudi Aramco has drilled a well in its East Ghawar shale, which Gratto compared to the Eagle Ford, both in terms of the rock and the output of the first well, though he did not offer details.

The test well was the first successful propped fracturing job in the country and tested four fracturing methods at different stages. “We learned enough to go the next horizontal well,” Gratto said. Next year, the national oil company is planning 10 wells, with a mix of vertical and horizontal holes.

Top 10 Countries with Shale Gas ResourcesBased on estimates by the US Energy Information Administration, these countries offer the most potential for shale gas production, but many factors must align for that potential to be realized.

Source: World Shale Gas and Shale Oil Resource Assessment, EIA and Advanced Resources International |

Altered Perceptions

While surging US production of oil and gas is widely seen as an American success story, other countries focus on how much it costs, how it affects the landscape, and the water used. They expect to benefit from the US experience.

To make that point, David Paddock, worldwide geophysical technical adviser for Schlumberger Unconventional Resources, showed a map of the Barnett and said, “It was an expensive map to make. It cost between USD 10 to USD 20 billion.”

The leaders in countries with large undeveloped shale reserves generally need to expand energy supplies, but expect to avoid the long, bumpy trial-and-error learning curve by “leveraging the American experience,” Paddock said.

In the US, as shale plays were identified, there was a rush to drill to hold leases before they expired. It speeded learning, but in most countries, government ownership of mineral resources eliminates that motivation.

“If you can go more slowly into it, you can learn more,” Paddock said, before outlining a detailed technical development program to improve the odds of drilling success.

On the other hand, private ownership of mineral rights in the US is seen as a positive because it offers an incentive to landowners to work with drillers. That incentive is not found in most other countries.

That incentive is one of the aboveground requirements that needs to be paired with subsurface resources to create the conditions needed for development of unconventional resources. Also on the list are adequate roads, pipeline capacity, skilled labor, water, and workable government policies.

No country offers all the factors that made the US such fertile ground for rapid unconventional growth. Other countries have differing gaps to fill:

- In the United Kingdom, small seismic events associated with some of the earliest fracturing in 2011 led to a moratorium on fracturing. In the meantime, Cuadrilla Resources worked on a required exploration plan that generated a 4,500‑page document that has been submitted to regulators for review. It hopes to be allowed to drill four wells in a year, said Andrew Quarles, technical director for Cuadrilla.

- In Saudi Arabia, exploration has begun in several promising areas. Development will require added pipeline capacity, water sources in the desert that do not compete with public needs, and a local source of the sort of sand needed for proppant.

- Argentina has been among the most active drillers, with 250 wells drilled. On the plus side, Chevron said its drilling partner, YPF, has found ways to cut the cost of drilling a well from USD 12 million to USD 7 million, Smithard said. But proppant is imported from Brazil, multiplying the cost compared to locally sourced materials, he said.

- In Australia, the geologic challenges include unpredictable underground stress patterns, and some prospects are in remote locations where water and labor are both scarce, said Ray Johnson, a principal at Unconventional Reservoir Solutions.

“We still do not have the critical mass to do the number of wells we want to do,” Johnson said.

Australia and Argentina both rank among the top 10 in the world in estimated shale gas resources, according to the US Energy Information Administration (EIA), as is South Africa, which is also an area where Chevron is active.

Managing Expectations

The release of the EIA international resource estimates was an event in countries that were not big oil and gas producers, such as South Africa. For international oil companies, this presented a problem because the headlines created lofty expectations among government leaders.

Smithard said the EIA outlook failed to explain the costs, challenges, and uncertainty involved. These tight formations had never been drilled, the country lacked the people, roads, and equipment needed for mass production drilling and completions, and if gas was found, they did not have the pipelines to deliver it.

“We need to educate them of the risk and uncertainties, and the support we need,” he said. “Often, we need to innovate as much financially as we do technologically.”

A different mind-set is also required for those developing unconventional resources. Saudi Aramco created a “company within a company” with a goal of creating a flexible culture capable of starting something new and “continuously learning from well to well,” Gratto said.

In the UK, the services and infrastructure are there—near where Cuadrilla plans to drill is a large gas line with available capacity—but the key issue is obtaining local permission to move in the equipment needed to drill and produce wells, Quarles said.

While there is vocal and well-organized opposition to developing shale resources, he said a public opinion survey found only 11% of the people said they were opposed to it, 43% supported unconventional development, and 45% are undecided. Winning over the undecided will require living up to plans designed to minimize the disruption caused by well development—Quarles described it as having local empathy—and filling the gas supply gap as North Sea production declines.

In the UK, natural gas sells for USD 10/Mcf and domestic production has been falling since 2000. There is enough gas in the ground to reverse the decline, Quarles said, adding, “The potential in the UK is staggering.”

For Further Reading

URTeC 1926712 Uncharted Waters: What Can We Learn From Waters Produced From Horizontal Wells in the Permian Basin? by Matthew Laughland, David Nelson, Paul Wilson, Emily Eastridge, Pioneer Natural Resources.

URTeC 1922257 The Benefits of Reinjecting Instead of Flaring Produced Gas in Unconventional Oil Reservoirs by Todd Hoffman, Montana Tech; Steve Sonnenberg, Hossein Kazemi, and Qi Cui, Colorado School of Mines.

URTeC 1922932 Impact of Light Component Stripping During CO2 Injection in Bakken Formation by Fai-Yengo, H. Rahnema, New Mexico Tech, M. Alfi, Texas A&M University.

URTeC 1922538 EOS Modeling and Reservoir Simulation Study of Bakken Gas Injection Improved Oil Recovery in the Elm Coulee Field, Montana by Wanli Pu, Colorado School of Mines, Todd Hoffman, Montana Tech.

URTeC 1891560 A Review of Enhanced Oil Recovery Methods Applied in Williston Basin by Kegang Ling, University of North Dakota, Zheng Shen, Weatherford, Guoqing Han, China University of Petroleum, Jun He, Pei Peng, University of North Dakota