ExxonMobil recently shared new details about an in-house innovation being scaled across the Permian Basin where the company produces more than 1.6 million BOE/D as the region’s largest operator.

Over the past couple of years, the US supermajor has steadily increased its use of petroleum coke, or petcoke, sourced from its own refineries in Canada and Texas to stimulate shale wells and the results show why.

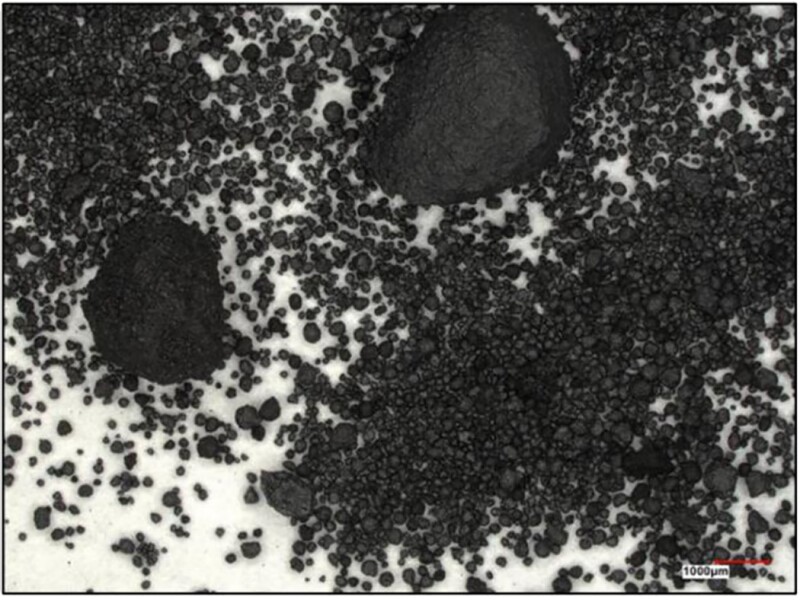

ExxonMobil reports that horizontal wells pumped with regular sand plus a dose of its petcoke, which looks like black sand to the naked eye, consistently deliver 7 to 18% more production in their first year than those hydraulically fractured with sand only.

The competitive advantage petcoke holds as a proppant boils down to its ability to move with sand, then reach parts of the fracture network that sand cannot. And by demonstrating this, ExxonMobil has effectively repurposed one of its lowest-margin hydrocarbon products into a subsurface technology that generates far greater value when used at the very start of an oil well’s life.

ExxonMobil presented details about some of the first trials of petcoke proppant at the Unconventional Resources Technology Conference (URTeC) in Houston earlier this year. In URTeC 4264319, the company highlights that the proprietary version of petcoke it is using is significantly lighter and more buoyant than sand, yet offers comparable strength and remains equally inert to fracturing fluids and the formation.

“These properties help transport the proppant further into fractures and keep more fracture area open compared to sand. This allows us to lower overall drilling and completion costs and increase production rates—so we’re bullish on it,” said Jimmy Jin, an ExxonMobil research engineer focused on advanced completions and well management.

Bullish seems an apt description of the company’s outlook on adoption.

Jin told JPT that ExxonMobil is moving “at an accelerated pace” to deploy petcoke proppant across its Permian footprint.