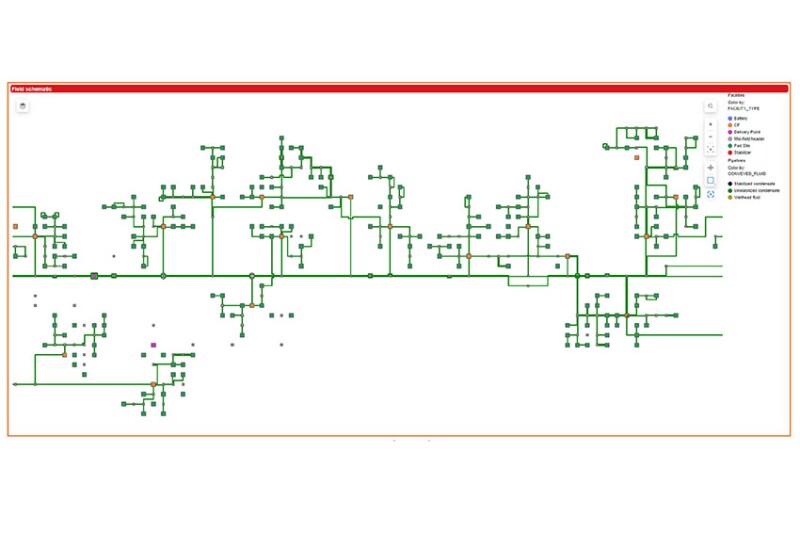

Since the beginning of Eagle Ford development, paraffin production has created significant production losses in wells downhole, well pads, and gathering systems. In 2020, a dedicated team began investigating a more-proactive approach with the creation of an integrated hydraulic model to improve pigging operations within the gathering system. The complete paper explains that, through the discovery of specific pressure trends at pad level (surface), combined with an unconventional approach for analyzing gas compositional data, it was possible to both detect and predict paraffin deposition at the pad level and in the gathering system, including conditions where paraffin was in suspension.

Introduction

Between 2011 and 2018, the operator’s Eagle Ford team implemented several projects with the objective of mitigating production losses associated with paraffin plugs in the gathering system, including testing a different surface-facility pad configuration. This configuration is equivalent to having a miniature central facility for each well where fluids are completely separated and measured before leaving the pad area.