As the oil price downturn continues to impact market stability, and its older reservoirs produce diminishing returns in the face of high energy demands, the Abu Dhabi National Oil Company (ADNOC) has recently focused on new technology development and qualification as a key function of its operations moving forward.

One such initiative aimed to develop ADNOC’s technological goals is a collaboration with BP to form an earth surface technology center in Abu Dhabi. And, in seeking to boost recovery from its assets and meet its production targets, the company created its own standards for qualifying new technologies, thus helping it realize strategic production targets and lower overall development costs. Based on the qualification standards of other operating companies and the US National Aeronautics and Space Administration (NASA), ADNOC’s standards on new technologies is set to deploy by the end of the year.

Earth Surface Technology Center

BP and ADNOC have collaborated on a number of joint venture projects recently, including technological initiatives. BP sends employees to Abu Dhabi to provide technical and managerial support to ADNOC and its operating companies. And last year, at the Abu Dhabi International Petroleum Exhibition and Conference (ADIPEC), the two companies announced the signing of a memorandum of understanding (MOU) for the development of a center for earth surface technology. The center aims to help improve the optimization and management of oil reservoirs and increase extraction of oil and gas from hydrocarbons in the emirate of Abu Dhabi, the largest of the seven emirates comprising UAE. The MOU was a result of technical discussions which began between the companies in 2014.

Under the terms of the MOU, BP will provide technical assistance to ADNOC for setting standards for works and products, which will be aimed at improving performance through the enhanced oil recovery technique.

New Standards

To qualify new technologies for deployment in field operations, ADNOC has historically relied on disparate processes for each of its operating companies, and the operating companies have relied on respective shareholder and service company processes. These processes had been developed and tested for various environments, some of which were not similar to operations in the Middle East.

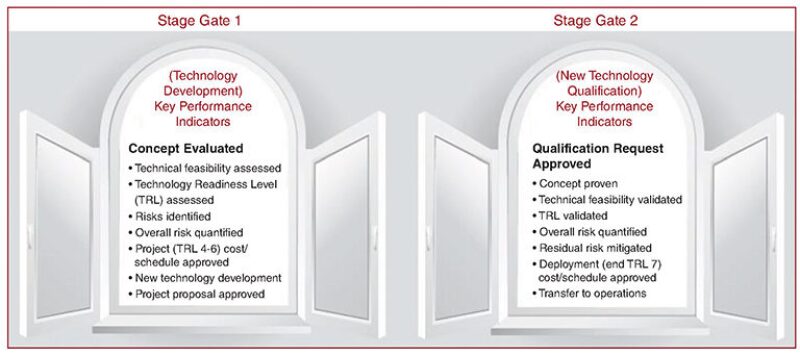

ADNOC integrated various policies from its operating companies to create its own standard process for the qualification of new technologies. It uses the Technology Readiness Level (TRL) as a primary tool in developing its standards. Originally developed by NASA, TRLs are used to progress the development of new technologies along a structured path toward deployment or commercialization. Strategically positioned stage gate parameters help the company assess the maturity and inherent risk associated with a new technology as it advances from one stage of development to the next.

Stage gates are positioned along a technology development path to facilitate transitioning the new technology along each phase, while staying focused on applicability and profitability and reducing the likelihood of what is often described as the “Valley of Death,” the gap between fundamental research in lower TRLs and technology deployment and/or commercialization in the higher TRLs.

The Qualification Process

The TRLs comprise a series of linked activities which may vary in number and duration as a function of the criticality of the technology element and the relative magnitude of the investment in that element. Typically, each stage costs more than the preceding one, resulting in an increasing commitment to new technology. As uncertainties decrease, risk is reduced and the investments are allowed to increase.

ADNOC divided its TRLs into three stages:

- Stage 1: Strategic or operational impact evaluation, which examines the alignment of new technology with business strategy and the estimates

- Stage 2: Technical evaluation, which establishes the feasibility, maturity, and alignment of the technology with technology development portfolios

- Stage 3: Business evaluation, which compares the resource investment with the expected return on that investment, as well as the effect of intellectual property roadblocks in the way of commercializing the new technology.

The stages are separated by two management decision points which satisfy established key performance parameters (KPPs). The KPPs in Stages 1 and 2 define the performance goals that the new technology must attain to enable advancement to the next stage. Appointed cross-functional teams must successfully complete a prescribed set of linked activities and satisfy the KPPs within each stage before obtaining approval on whether to advance the technology to the next stage of development.

The qualification process was developed to be specific to the local environment and most responsive to the relevant technical challenges of ADNOC’s operating companies. Only technologies with managed risk and improved performance will reach the operations team.

Sherif El-Gharbawy, technology maturity manager in ADNOC’s research and development division, said the strategy will help encourage innovation in ADNOC’s group of operating companies, which means developing and promoting technologies that are not mature and established within the industry. In the current low-price oil environment, however, El-Gharbawy said that any company looking to build its portfolio must take risks on new technologies.

“Operators have two options to remain afloat: Increase output and decrease production cost,” El-Gharbawy said. “Either one of these options requires them to experiment with processes and technologies that have not been matured.”

ADNOC evaluates concepts in the first stage gate. The technical feasibility of a new technology is assessed, and the overall risks are identified and quantified. The company will determine the project’s cost and schedule in this stage and approve the proposal. In the second stage gate, the company evaluates the qualification request. It will test the concept behind the new technology and validate the technical feasibility. Residual risk is mitigated. Once the deployment schedule is approved, the project is transferred to the operations team.

Collaborative Process

ADNOC met with several national and international operating companies as it established its qualification standards, including BP, Halliburton, Total, and Shell. The company discussed these different policies during last year’s ADIPEC.

BP considers “make vs. buy” decisions as they partner with universities and customers to develop and qualify new technologies. BP’s technology qualification process has the overarching goal of no accidents, no harm to people, and no damage to the environment. BP recommended that ADNOC ensure enough effort is spent upfront to define new technology needs before diving into development.

Total and Shell’s qualification processes focus on reducing the unknowns associated with new technologies to prevent undesired outcomes. Both companies employ stage or decision gates in their processes to make sure that only those with an acceptable level of uncertainty make it to operations.

Halliburton saw that the first step toward technology development was mapping operators’ technical challenges to be able to focus investment on viable solutions specific to those challenges. The company emphasized developing its own maturation process for new technologies based on the TRL framework.

Looking Ahead

One of the primary keys to ADNOC’s TRL process was selling the idea to stakeholders. It sought to increase confidence in new technology by minimizing risk to a level that can be managed or mitigated by its operations teams. It also wanted to maximize efficiency by centralizing the process of qualifying new technologies, maintain a catalogue of qualified new technologies accessible to each of ADNOC’s operating companies, and maximize its return on investment in the research and development of new projects.

ADNOC is currently testing its new process on a small number of technologies at the first and second stage gates. Once its management and operating companies approve the process, it will become standard practice. El-Gharbawy also said the qualification strategy will be incorporated into ADNOC’s research and development contracts.

“We are integrating the new process into our R&D project contracts so as to influence the maturity of our new technologies and enhance our technology development efforts by bridging the gap between stage gates,” El-Gharbawy said.

For Further Reading

OTC 27058 Technology Qualification for ADNOC Group Operations in the Arabian Gulf by S. El-Gharbawy and W. Beydoun, ADNOC.