Woodside announced 11 June that the Léopold Sédar Senghor floating production, storage, and offloading (FPSO) had received oil from Phase 1 of its operated project.

The Léopold Sédar Senghor FPSO, named after the first president of Senegal, can process 100,000 BOPD, inject 130,000 BOWD, and store 1.3 million bbl of oil. It is moored in 2,560-ft water depth.

Phase 1 of the development includes 11 production wells, 10 water-injection wells, and 2 gas-injection wells. Of those 23 wells, all but two of the production wells have been drilled and completed. The project joint venture has also approved an additional production well to be completed in the current campaign, bringing the total number of wells for the first phase to two dozen.

According to Woodside, 80% of Phase 1 recovery is from high-quality S500 reservoirs, and crude quality is expected to be around 31 °API.

The first phase, sanctioned in 2020, is focused on developing the less-complex reservoir units and testing other reservoirs, targeting approximately 230 million bbl of crude oil.

During a conference call discussing the project, O’Neill said, “The resource size, there's no dispute that that is large. What we've seen in the development wells is permeability that's at the upper end of what we had anticipated pre-drill, so we were thinking it would be 50 to 100 millidarcies, and what we've been seeing through the bit is 100 to 150, so modestly better.”

She said the ability to image the reservoir has been really strong, as has the geosteering effort on the project.

“The key piece of data that we don't have yet is the connectivity between injector and producer. So, we'll be looking to get that as quickly as we can because that really is the critical data that will help us understand how much of the end place we can recover,” she said. “The reservoir quality has been very, very close to our pre-drill prediction. So, the S500, this is the lower sands, very high-quality, highly continuous reservoir. This is the sweet spot that we're targeting with the Phase 1 development.”

She said drilling has reached the high-quality reservoir sands that the operator expected.

“We've been drilling very long, horizontal wells, so something like 1500-m horizontal wells,” she said. The geosteering technology we're using enables us to place the well very precisely and understand offset from things like gas cap and water contact.”

She said that from a well capacity perspective, Woodside is seeing capacities up to 20,000 B/D in the S500s.

“The first well that we're flowing has been flowing at 20,000 B/D for our target first-oil period of 72 hours,” O’Neill said.

The S400, “where there is significant in-place oil potential,” is an aerially extensive large reservoir that is geologically more complex with lower permeability, she said. There is a question about the ability for water to sweep from the injection wells to the production wells in the S400 due to complexity revealed by seismic data involving smaller geologic bodies, she added.

The project has a pilot in S400 reservoirs using four injector-producer pairs to test for connectivity between injectors and producers

“We believe that there should be communication along the length of these bodies. We were very successful in placing the wells, and as I said, drilling through the different geobodies that we have targeted, but the key is to get that dynamic data. That dynamic data will start to come in towards the backend of this year. We'll need to have a bit of time to understand how the reservoir is performing, update our models. So, I'd say it will take 12 to 24 months to really understand what's happening in the S400s and what that means for future phases of development,” O’Neill said.

She said that data will inform FEED work for future phases, but that Woodside designed the facility to enable that expansion potential.

The drilling campaign at Sangomar is ongoing, and Woodside expects to continue commissioning activities and ramping up production in a stepwise fashion through 2024.

Woodside said estimated costs for Phase 1 of the project remain between $4.9 and $5.2 billion.

MODEC constructed the FPSO and is responsible for operating and maintaining it for a decade with an option for a 10-year extension.

Diamond Offshore Drilling handled drilling, and the Subsea Integration Alliance of Subsea7 and OneSubsea handled construction and installation of subsea production systems and subsea umbilicals, risers, and flowlines.

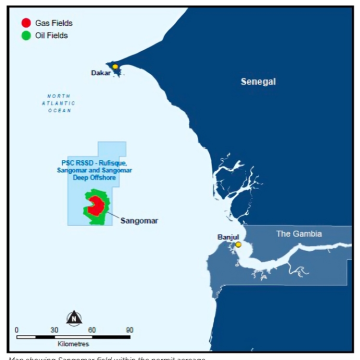

The Rufisque Offshore, Sangomar Offshore and Sangomar Deep Offshore (RSSD) joint venture is progressing the Sangomar project. RSSD includes Woodside as operator with 82% interest and Societé des Petroles du Sénégal (PETROSEN) with 18% interest.