Surveillance of a subsea boosting system in 9,500-ft water depth gave an operator the confidence to defer pump replacement and led to a 10% increase in Stones field’s production in the US Gulf of America (renamed from Gulf of Mexico).

With subsea boosting increasingly needed to keep fields like Stones producing at high volumes, monitoring the boosting systems allows operators to plan equipment replacement at optimal times, Andrew Merlino, artificial lift subject matter expert at Shell, said while presenting OTC 35857 at the Offshore Technology Conference in Houston in May.

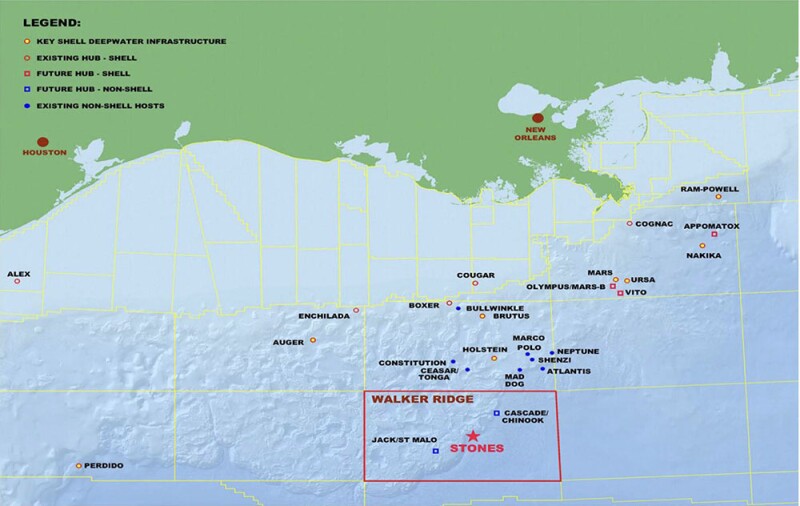

By implementing surveillance of the boosting equipment, he said, Shell can maximize its assets in the Stones field in the Walker Ridge area (Fig. 1).

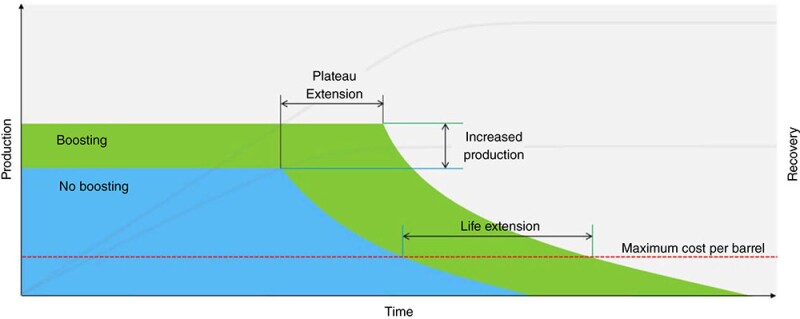

Subsea boosting can prolong a field’s life because it unlocks resources when the reservoir’s energy alone cannot produce and send the hydrocarbons to a surface process facility (Fig. 2).

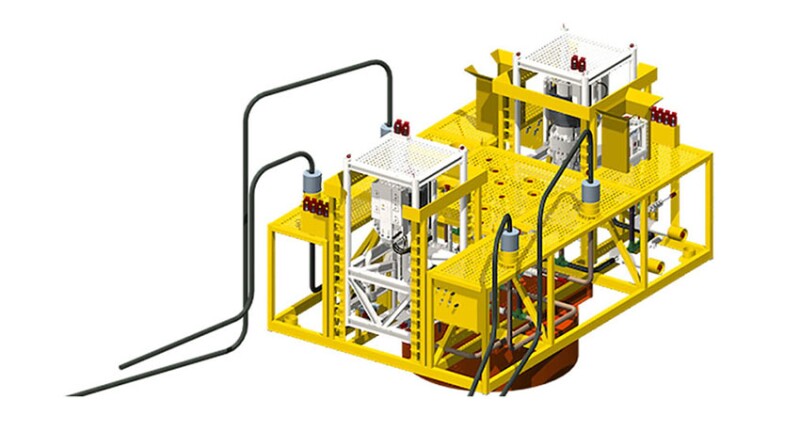

The ultradeepwater Stones field uses a subsea boosting system that includes two 3-MW single-phase pumps. The field, discovered in 2005, began production of 24–28 °API oil to the Turritella floating production, offloading, and storage (FPSO) vessel in 2016. The boosting system was deployed in 2019 to counterbalance the effect of the hydrostatic column on production from the field’s eight subsea wells, which target reservoirs at more than 26,000-ft total depth.

Given the complex reservoir and ultradeepwater nature of the Stones field, Merlino said the team had many factors to consider when choosing the optimal artificial lift system to serve the Paleogene discovery.