Completions

Ranger acquires American Well Services for $90.5 million, adding 39 workover rigs and boosting its fleet by 25%.

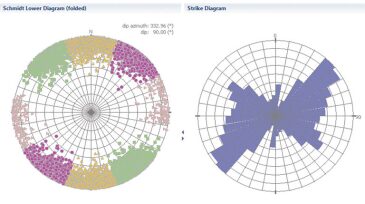

In this third work in a series, the authors conduct transfer-learning validation with a robust real-field data set for hydraulic fracturing design.

This paper describes development of a high-temperature water-based reservoir drill-in fluid using a novel synthetic polymer and customized with optimal chemical concentrations and sized calcium carbonate.

-

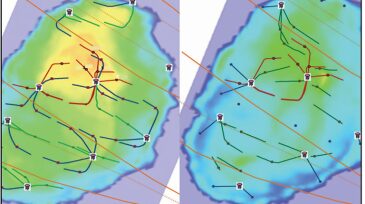

This paper presents a unique work flow that addresses in real time the challenges of perforation and fracture-treatment design while accounting for the lithologic and stress variability along the wellbore and its surroundings.

-

In this study, a laboratory analysis was conducted to study the effect of a phosphonate-based scale inhibitor on a mixture of hypersaline Arabian Gulf seawater and formation water under high-temperature/high-pressure conditions.

-

The very first fracturing job used sand scooped from a nearby river. After decades of buying sand based on tight size standards, unconventional operators are increasingly going back to a broad range of sizes, similar to that river sand.

-

Wadhah Al-Tailji, technical manager at StrataGen, shares his latest technical reads.

-

In the fast-moving US shale sector, no market trend seems to last long. The pressure pumping market exemplifies the maxim.

-

"I have some patients whose symptoms I can’t explain," physician Ulrike Meyer said, describing nosebleeds, rare cancers, and respiratory illness among a dearth of data.

-

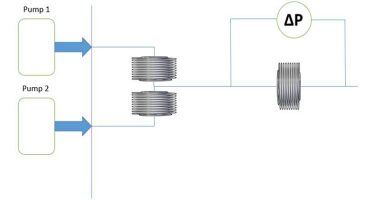

This paper uses a simulation model to evaluate and compare the thermal efficiency of five different completion design cases during the SAGD circulation phase in the Lloydminster formation in the Lindbergh area in Alberta, Canada.

-

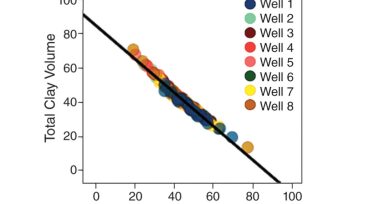

This paper demonstrates how engineers can take advantage of their most-detailed completions and geomechanical data by identifying trends arising from past detailed treatment analyses.

-

The operator piloted a new well-completion design combining inflow-control valves (ICVs) in the shallow reservoir and inflow-control devices (ICDs) in the deeper reservoir, both deployed in a water-injector well for the first time in the company’s experience.

-

This paper covers the staged field-development methodology, including analysis and evaluation of various development concepts, that enabled the company to optimize both completion design and artificial-lift selection, reducing downtime and lowering operating costs by nearly 50%.