Drilling

Rystad Energy expects the continent to account for the largest share of frontier and basin-opening wells in 2026 as operators pursue scale and untapped resources.

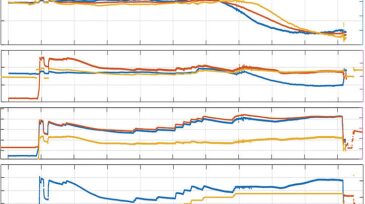

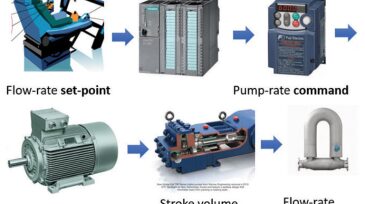

This paper presents a multifaceted approach leveraging precise rig control, physics models, and machine-learning techniques to deliver consistently high performance in a scalable manner for sliding.

This paper proposes a novel approach toward drilling maximum-reservoir-contact wells by integrating automated drilling and geosteering software to control the downhole bottomhole assembly, thereby minimizing the need for human intervention.

-

Transocean reported a long list of reasons why the deepwater drilling business is coming back strong. Making money is still not one of them.

-

Sometimes problems turn out to be an opportunity to try something new. In this case, the result was a well design unlike anything most in the shale sector have seen before.

-

Hess is testing whether it can drive drilling improvement by combining drilling rigs equipped with automated functions and humans determined to find a way to beat the programmed drilling.

-

Rigs drilling faster earn less money per foot because they are contracted by the day. But at least they are still working. Now service companies are developing new rigs with more automated functions, and want increased rates based on the productivity gains achieved.

-

This paper shows how high-frequency, real-time drilling data from wired drillpipe has helped optimization of drilling performance and achievement of additional improvements in the New Mexico Delaware Basin.

-

This paper describes how new technology was implemented and deployed through a downhole acoustic network through a sequence of runs in complex North Sea wells under managed-pressure conditions.

-

This paper discusses how oil and gas companies are using a new generation of AI-driven applications powered by computational-knowledge graphs and AI algorithms to create a digital knowledge layer for oil and gas wells that provides a timeline of significant well events.

-

Drilling systems automation (DSA) is moving into commercial activities on a broad front. Equipment suppliers are delivering automated drilling-control systems, and everyone (equipment suppliers, service companies, drilling contractors, operators) is delivering systems-automation applications.

-

The complete paper presents a process used to successfully implement a rig-based drilling advisory system (RDAS) across a mixed group of rig contractors.

-

The complete paper presents a drilling semantic framework that allows software solutions to achieve automatic and versatile self-configuration.