Drilling

The London-headquartered independent acquires position in the US Gulf while preparing Zama for final investment decision.

This study identifies critical knowledge gaps in wellbore integrity and underscores areas that require further investigation, providing insights into how wellbores must evolve to meet the technical demands of the energy transition.

This study illustrates the new capabilities, tailored for CO₂ storage applications, of a modeling framework that provides a quantitative, risk-based assessment of the long-term integrity of legacy plugged and abandoned wells.

-

Wireline continuous coring (WCC) has been adapted from the mining industry for unconventional resources. This paper is aimed at identifying and addressing complications experienced in the use of WCC.

-

A number of companies are pushing for alternative approaches to offshore development that seek to access marginal reservoirs. Their differing and unique ideas call for a departure from the usual playbook, but share a common goal of slashing capital costs.

-

Precise casing-wear prediction is important for improving well integrity and longevity, while simultaneously making casing designs more cost-effective. There are no industry guidelines for casing-wear prediction. This article presents a validated predictive model.

-

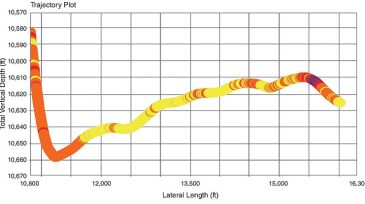

This paper analyzes differing well-factory approaches to unconventional assets, with examples from the Wolfcamp unconventional oil play in the Permian Basin.

-

Anyone selling something new for offshore exploration and production has to be able to answer a simple question from customers, “How can we save some money?” For Norwegian oil companies, change is coming in many forms: steel, sensors, software, and standards.

-

Baker Hughes is developing a drill bit capable of auto-adjusting its depth-of-cut feature to handle dynamic drilling conditions.

-

Challenging environments such as unstable clay formations represent high operational risk when running tubulars after drilling is completed.

-

A real-time method is presented to predict impending stuck pipe with sufficient warning to prevent it. The new method uses automated analysis of real-time modeling coupled with real-time-data analysis.

-

Larger-diameter coiled tubing recently has been used to perform millouts because of its improved set-down force and increased annular velocities for cleanout purposes. Service companies and operators have reduced the number of wiper trips when using larger-diameter CT, to save time and money.

-

The force required to drill through a rock is a direct test of its strength and stiffness. Developing a reliable measure of the properties of rock based on the force required to drill a long lateral is a large challenge.