Enhanced recovery

As the industry accelerates carbon capture, use, and storage initiatives, modeling innovations for carbon-dioxide injection and enhanced oil recovery have become critical for optimizing recovery and ensuring secure storage. Recent studies highlight a shift toward data-driven and hybrid approaches that combine computational efficiency with operational practicality.

Operators are turning to new gas-lift and nanoparticle-fluid technologies to drive up production rates.

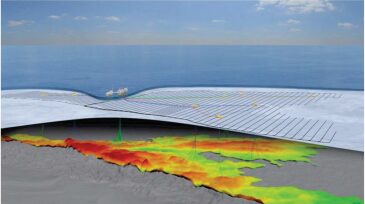

This paper addresses the difficulty in adjusting late-stage production in waterflooded reservoirs and proposes an integrated well-network-design mode for carbon-dioxide enhanced oil recovery and storage.

-

The challenge is immense, but the promise is, too. If the oil and gas business can scale up CO2 EOR, then it can play a very big role in mitigating climate change while offering carbon-negative fuels.

-

Though shelved by low oil prices, the plan to execute the largest enhanced oil recovery program of its kind offers insights into what it may take for the shale sector to escape pilot mode and scale up gas huff ’n’ puff operations.

-

Before the giant Johan Sverdrup field had produced even one barrel of oil, operator Equinor and its license partners set a recovery ambition of greater than 70% for the field.

-

The complete paper discusses optimization of a development plan involving low-salinity water injection.

-

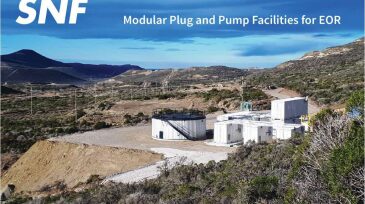

SponsoredPolymer flooding increases the RF up to 20% at $3 to $6 per extra bbl of oil. It also contributes towards reducing CO2 emission by 3–6 times per bbl. It’s a proven technology with more than 300 projects worldwide. SNF offers modular plug and pump facilities connected to existing infrastructure.

-

Add Denbury Resources to the list of oil companies filing for bankruptcy protection with a plan that may make for a quick trip through the debt-reduction process.

-

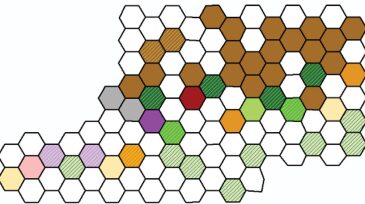

The complete paper presents a large-scale work flow designed to take a vast amount of data into consideration. The work flow can be scaled for projects of any size, depending on the data available.

-

What the industry needs at this stage is a willingness to work together, share best practices, conduct innovative research, and focus on disruptive technologies that lower cost of capture and make our operations more sustainable.

-

Duri Field in Indonesia is the largest active steamflood project in the world. The field produces 73,000 BOPD, and 10,000 optimization jobs are executed annually to support base production.

-

In difficult times, there is naturally a focus on maximizing the operational efficiency of existing assets, including enhanced-oil-recovery (EOR) operations and looking for capital-efficient ways to increase the resource base in existing assets.