Enhanced recovery

Operators are turning to new gas-lift and nanoparticle-fluid technologies to drive up production rates.

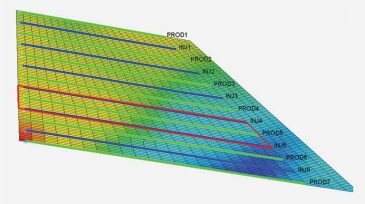

This paper addresses the difficulty in adjusting late-stage production in waterflooded reservoirs and proposes an integrated well-network-design mode for carbon-dioxide enhanced oil recovery and storage.

This work presents the development of fast predictive models and optimization methodologies to evaluate the potential of carbon-dioxide EOR and storage operations quickly in mature oil fields.

-

In recent years, some effort has been made to use EOR techniques, particularly CO2 injection, to extract additional oil and gas from unconventional resources. This has the potential to change the dynamics (again) of oil production from these tight and difficult reservoirs.

-

One of my best moments is to have made the technical case for polymer flooding and to see the fruits of this several decades later. As is so often the case in our industry, my contribution stands alongside those of many others in the intervening years who have all made the EOR journey possible.

-

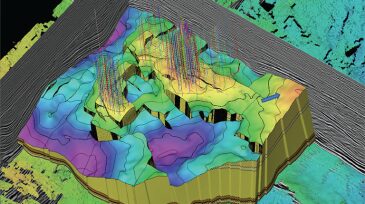

A thermal asset in Oman is characterized by a large-scale steam-drive/cyclic-steam-soak development project, underpinned by extensive data gathering.

-

This paper discusses an enhanced-oil-recovery (EOR) polymer-flood pilot at the Captain field in the UK North Sea during 2011–2013.

-

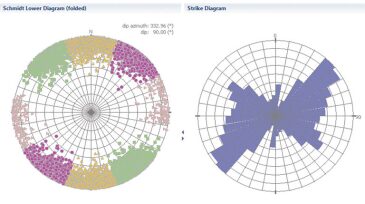

This paper discusses the operation of the largest offshore high-pressure water-alternating-gas (WAG) injection pilot using hydrocarbon (HC) gas, with a gas-injection capacity of approximately 100 MMscf/D, in the giant Al-Shaheen field offshore Qatar.

-

There is every reason to believe that enhanced oil recovery through huff-and-puff injections in US tight-oil plays could be a technical success across large numbers of wells. However, widespread economic success remains uncertain.

-

Aker Solutions and FSubsea have agreed to a joint venture, named FASTSubsea, to help operators increase oil recovery.

-

SponsoredMesser and Nissan Chemical recently introduced a new Huff ’n’ Puff process that combines CO2 or N2 gas and nanoparticles for synergistic multi-spectrum recovery enhancement from aging, depleted wells.

-

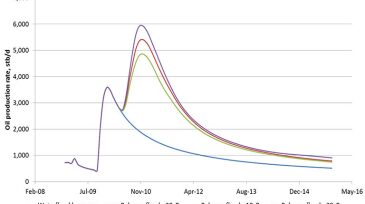

This paper covers the staged field-development methodology, including analysis and evaluation of various development concepts, that enabled the company to optimize both completion design and artificial-lift selection, reducing downtime and lowering operating costs by nearly 50%.

-

This paper shares experience gained in the Ashalchinskoye heavy-oil field with a two-wellhead SAGD modification. As a result of a pilot for this technology in Russia, the accumulated production of three pairs of these wells is greater than 200,000 tons.