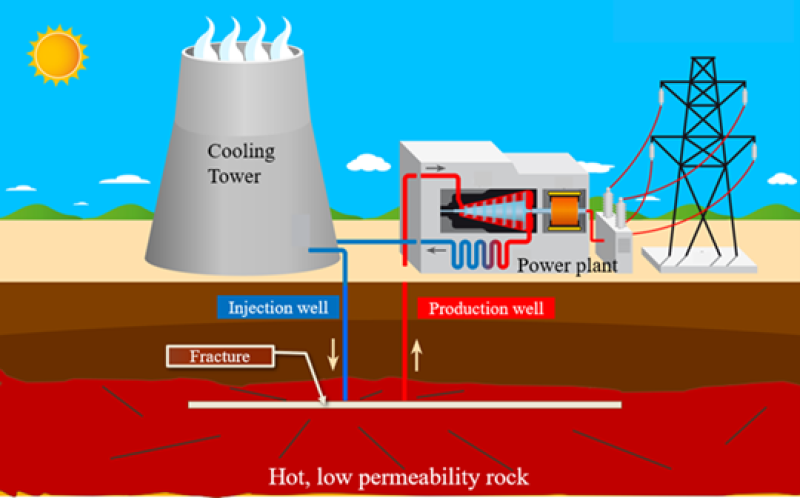

Enhanced geothermal systems (EGS) make it possible to produce geothermal energy from hot rocks that do not naturally contain enough fluid or permeability. Instead of relying on existing hydrothermal reservoirs, EGS create artificial flow paths through stimulation, allowing injected fluid to circulate through hot rock and recover heat. This approach greatly expands where geothermal energy can be developed, but it also raises important questions about how heat should be extracted to avoid rapid thermal decline. The visual representation of EGS is shown in Fig. 1.

EGS are commonly operated under continuous circulation, where cold fluid is injected and hot fluid is produced simultaneously to maximize power generation. While this approach is operationally simple and aligns well with baseload electricity delivery, it often accelerates thermal breakthrough in fractured, low-permeability reservoirs. Numerical simulations and field-scale modeling show that continuous flow preferentially cools dominant fracture pathways, leaving large volumes of rock thermally underutilized once breakthrough occurs. This behavior is clearly illustrated in long-term continuous EGS simulations, where production temperature declines sharply after breakthrough and stabilizes at a significantly lower level despite ongoing injection (Sekar and Okoroafor, 2024).

Recent research has revisited an alternative operational strategy adapted from unconventional oil and gas development: the huff-‘n’-puff technique. In geothermal applications, huff-‘n’-puff introduces cyclic injection, soaking, and production phases that intentionally pause fluid circulation (Fig. 2) . These pauses allow heat to conduct from the rock matrix back into fractures, partially recharging the thermal system before production resumes. Fully coupled thermo-hydro-mechanical simulations demonstrate that this cyclic operation fundamentally alters heat-transfer dynamics by increasing fluid residence time and reducing short-circuiting through dominant fractures (Sekar et al., 2024).

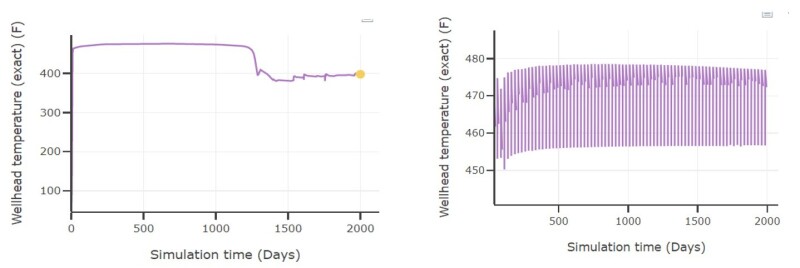

The thermal benefit of this approach is evident when comparing production temperature histories between continuous and huff-‘n’-puff systems. In comparative simulations using identical reservoir and stimulation parameters, the continuous case exhibits a pronounced temperature drop after approximately 1,200 days, followed by a long-term plateau at a lower temperature.

In contrast, the huff-‘n’-puff case maintains elevated wellhead temperatures with negligible long-term decline over the same cumulative injection volume. This contrast is shown in the production temperature comparison (Fig. 3), where the huff-‘n’-puff system sustains temperatures nearly 100°F higher than the continuous system well beyond the continuous breakthrough point.

The underlying reason for this improvement lies in the role of soaking periods. During soaking, pressure gradients dissipate and conductive heat transfer dominates, allowing fractures and near-fracture rock volumes to re-equilibrate thermally. Sensitivity studies on soaking duration show that while excessively long soaking reduces cumulative production, moderate soak periods are sufficient to restore thermal gradients without significantly penalizing energy recovery. Simulation results indicate that increasing soaking time beyond an optimal range yields minimal additional temperature benefit while reducing total produced fluid, emphasizing the need for balanced cycle design (Sekar and Okoroafor, 2024).

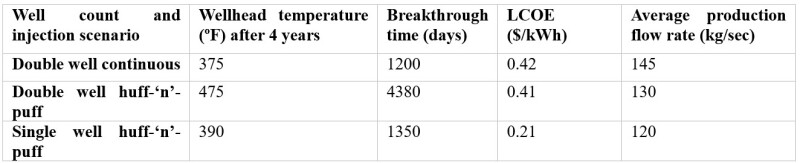

The economic implications of these thermal trends are nuanced. Techno-economic analysis using the Flexible Geothermal Economics Model (FGEM) indicates that in double-well configurations, huff-‘n’-puff systems achieve levelized cost of electricity (LCOE) values comparable to continuous systems despite lower capacity factors. This is primarily due to delayed thermal breakthrough and sustained production temperatures, which extend the economic life of the reservoir. In single-well configurations, huff-‘n’-puff systems show substantially lower LCOE, driven by reduced capital expenditure and lower pumping requirements (Sekar et al., 2024).

Importantly, huff-‘n’-puff is not universally superior to continuous production. Continuous operation remains favorable in reservoirs with sufficient permeability and distributed flow paths, where thermal sweep is efficient and breakthrough is delayed naturally. However, in tight or fracture-dominated EGS reservoirs, where early thermal decline governs project viability, huff-‘n’-puff provides a mechanism to slow depletion and recover heat that would otherwise remain inaccessible.

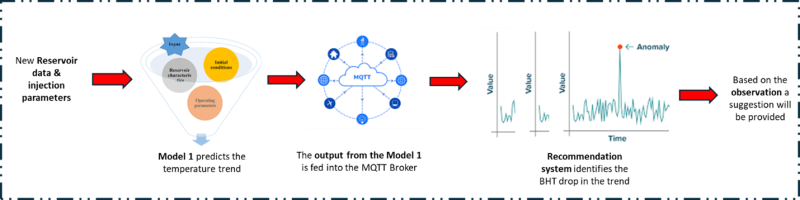

Recent advances in data-driven modeling suggest that the choice between continuous and cyclic operation does not need to be static. Machine-learning proxy models trained on coupled simulations can detect early deviations in bottomhole temperature trends and predict impending thermal breakthrough. These models enable adaptive operational strategies, where an EGS can operate continuously during early life and transition to huff-‘n’-puff as thermal decline begins, maximizing both short-term output and long-term recovery (Sekar and Okoroafor, 2025).

The typical proxy modeling workflow to predict thermal breakthroughs and change the injection pattern is shown in Fig. 4.

As geothermal development expands to deeper, tighter, and more heterogeneous formations, operational flexibility will become increasingly important. Huff-‘n’-puff should not be viewed as a replacement for continuous EGS, but as a complementary strategy that can be deployed when reservoir physics demands it. By reframing geothermal production around heat management rather than fluid throughput, operators can unlock more value from the same subsurface resource.

For Further Reading

Numerical Investigation of the Impact of Fracture Aperture Anisotropy on EGS Thermal Performance by E. Okoroafor, Stanford University; C. Co, Chevron; and R. Horne, Stanford University.

Maximizing Geothermal Energy Recovery From Enhanced Geothermal Systems Through Huff-and-Puff: A Comprehensive Simulation Study by L. Sekar and E. Okoroafor, Texas A&M University.

Assisted History Matching Using Bayesian Inference: Application to Multiwell Simulation of a Huff-'n'-Puff Pilot Test in the Permian Basin by E. Eltahan, R. Ganjdanesh and W. Yu, The University of Texas, et al.

Optimizing Flexible Geothermal Energy Generation: A Techno-Economic Analysis Using FGEM for EGS Huff-'n'- Puff by L. Sekar, M. Aljubran, and E. Okoroafor, Texas A&M University.

AI-Driven Framework for Adaptive Thermal Management in Enhanced Geothermal Systems by L. Sekar and E. Okoroafor, Texas A&M University. Geothermal Rising Conference 2025 Proceedings, Vol. 49, pp. 277–286.