Resilient supply-chain management plays an essential role in organizational success. While an effective supply chain is dependent on logistics, inventory control, and materials handling, it is also strongly interlinked with the use of new technologies that will enhance the complete supply-chain cycle. The complete paper develops a framework that introduces 3D printing in the oil and gas industry, taking into consideration the challenges that this technology is facing to penetrate a generally conservative industry and realizing its potential benefits.

Sourcing Materials Challenges (As-Is Situation)

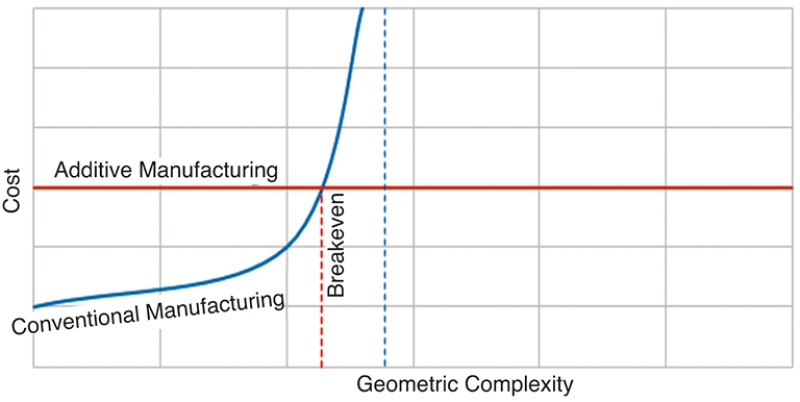

Additive manufacturing can play a vital role in resolving pains experienced by global aftermarket supply chains. It can help in dealing with obsolescence of materials after the end of service, when the materials are either not available in market, very costly, or missing technical drawings and data sheets.