Like money, there’s a time value to design ideas. A dollar earned sooner, and concepts produced faster, have added value. This is important because inflation will inevitably reduce a dollar’s buying power over time.

Generating design concepts faster can allow offshore projects to begin producing oil and cash flow sooner, and that is not the only way that faster offshore planning work can pay off, based two recent papers.

ExxonMobil evaluated a digital approach to generating and evaluating more design concepts faster, giving it a better chance of identifying the highest-value design concept, as described in a presentation of paper SPE 210288 at the 2022 SPE Annual Technical Conference and Exhibition (ATCE).

After that paper was presented, Occidental Petroleum offered methods that slashed the time required for a three-person team to evaluate the subsurface redevelopment options for an offshore platform (SPE 210199).

“This probably was a couple year type of project done in 6 months’ time,” said David Work, development excellence technical lead–geology for Occidental, who advised the team.

For Occidental, the quick turnaround was required because it was nearing the field’s 20-year design life. The three-person subsurface team was asked to find ways to profitably revive production and provide an understanding of the potential for future development.

ExxonMobil tested a computerized method for generating and evaluating offshore design concepts because the method promised to deliver hundreds of options in the time it would take a design team to generate a handful of options.

In this case, the time value of faster design could deliver a greater chance of finding and recognizing the most-valuable design concept.

“If you have a good concept, then your project value can he hugely higher," said Yifei Zeng, senior research engineer at ExxonMobil. During a presentation at ATCE where he introduced the theme of the day, he said, “Finding the highest-value concept can be really, really challenging.”

In both cases, the papers reported the new approaches delivered on their promise.

Using computer-generated ideas and evaluation, ExxonMobil create 120 design variations and evaluated the cost and value of these designs based on the high and low estimates of future production.

Based on that test using a hypothetical field created using actual offshore development and production data, this method is now being offered to the company’s development teams as a way to check the value of their design concepts, Zeng said.

The company that developed the idea-generating method, Deep Seed Solutions, has been advising clients on greenfield and brownfield offshore developments in Brazil, Gulf of Mexico, North Sea, and Africa, said Leandro Basilio, CEO for Deep Seed Solutions.

Since the work described in the Occidental paper, the team has moved on to other things. Work is now the Gulf of Mexico development excellence technical lead for Occidental, promoting methods like those described in the paper.

“My thought is we need to start applying it on other projects,” he said.

Computer-Generated Options

Generating just one design concept for an offshore field development is a time-consuming effort.

There are so many variables to consider, each of which can have long-term consequences that matter in different ways to the many people who will have roles over the life of the field, which means they will have conflicting views on how to develop it.

Developing multiple solutions to such a complex puzzle where critical pieces are uncertain—particularly future production—can be a slow-moving process.

“Using the current method, three to five development concepts can be developed in 8 to 9 months,” said Zeng, who delivered the paper. This limited number of options leaves decision makers wondering if they are choosing from among the best ideas on complex projects where the number of possible permutations is staggering.

The paper described a test of a faster way to generate and evaluate far more concepts offered by a partnership of the Strategic Decisions Group and Deep Seed Solutions.

Strategic Decisions is an established US consultant whose advice is built around a six-point method for sound long-term decision making, beginning with defining the objective and keeping it in mind throughout the process and ending with ensuring that key stakeholders are involved.

The partnership with Deep Seed offers what looks like an objective answer to the fifth point of Strategic Decision’s list: “Are we using a well-structured, logical method of evaluating the alternatives and reflecting uncertainty?”

The young Brazilian company, whose coauthors on previous SPE papers have included Shell Repsol and Sinopec, created the AI-based method that quickly assembles compatible design concepts based on its database of more than 250,000 items used for deepwater development, including their specifications, capacity, and price and evaluates how they are likely to perform.

The paper by ExxonMobil described how a computer was able in weeks to create 120 configurations based on differing inputs for five variables and also estimated their likely net present value (NPV) and capital expenditure (Capex) based on lower and higher production projections.

“Once you run this tool, this can rank which ideas are at the top in terms of NPV and investment” to determine the best value, said Sang-Won Kim, a partner in the Strategic Decisions Group. He added, “The best ideas are the best under many different evaluations.”

Based on the simulations, the difference in the value of the best and worst ideas was large.

Deep Seed’s Field Layout Concept Optimizer (FLOCO) was asked to create and evaluate design options based on five variables for ExxonMobil. A synthetic field was created for the test using subsurface and production estimates provided by the company, as is normal for the company which evaluates surface design concepts.

Since long-term field production levels are notoriously unreliable, they did two simulation runs for each design concept: one based on production 20% higher than expected and another assuming it was 10% lower.

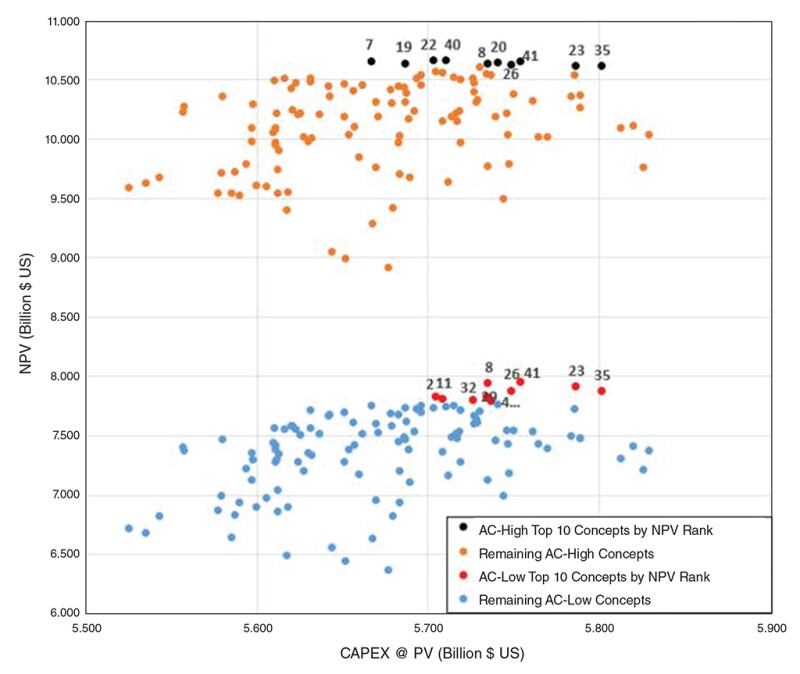

The 240 results were displayed as an array of dots plotted on a chart based on the Capex and the NPV (Fig. 1). Two clouds of dots based on the oil production estimate were evident and indicated that higher production means higher value.

The best concepts delivered an NPV that was as much as $1.6 billion greater than the lowest-performing ideas in both production scenarios, the paper said

Among the top designs, they highlighted five that ranked at the top, both when oil production is higher than expected and also when it is lower.

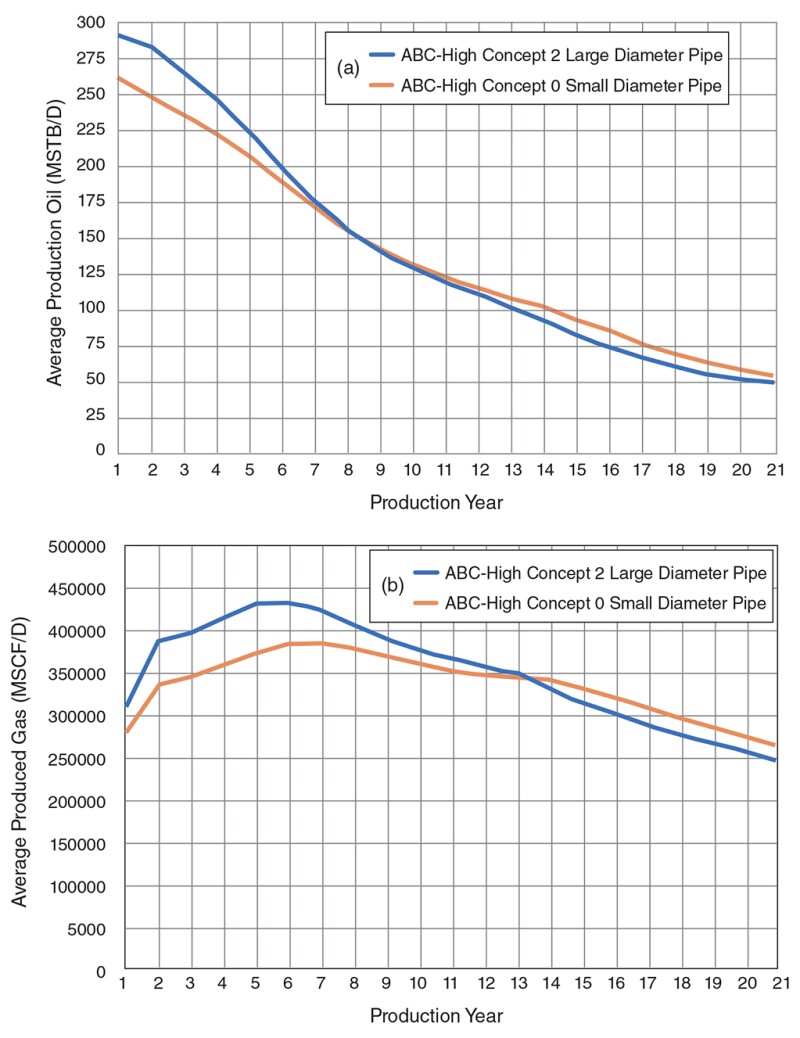

Of the five variables considered, the one with the largest impact on NPV was using a large-diameter pipe over a narrower pipe.

The reward for the larger-diameter pipe is not surprising—it would allow higher production during the peak early-production years—when the value of the dollars generated is higher. And this also would allow greater production over the life of the project, even though it was expected to mean lower production later than the smaller-diameter pipe (Fig. 2).

That is a benefit an experienced project planner would likely see as well, which begs a question the paper cannot answer: How would the best ideas from the computer run compare to the preferences of actual project planners, if they were asked to offer options?

Humans creating plans also would be aware of conflicting points of view about the goal of a good design. Greater pipe capacity early on can maximize returns, but big pipes will create problems for production engineers trying to maximize production when the field pressure and oil flow drop below the capacity of those lines.

The paper said this all argues for the value of have more options to consider upfront.

“You want to know you are making a good decision when you make the decision because you are not going to be able to adjust,” Kim said.

An Agile Scrum

A geologist and a geophysicist were put on a team and told they had 6 months to evaluate the remaining production potential of a field nearing the end of its 20-year design life.

This subsurface evaluation of the unnamed platform was part of a larger effort by Occidental to look for ways to maximize the value of the Gulf of Mexico fields bought from Anadarko, many of which were reaching the age where it was time to decide whether to extend their life (OTC 32122).

Their instruction was: “Let’s look through these fields to make sure we have turned over every stone. And make sure it is all documented,” said Work.

The subsurface information suggested there could be more oil and gas to find, but there were just so many stones to turn.

“There is a tremendous amount of stacked pay in the first field we looked at. There were 14 reservoirs to consider,” said Natasha Jeansonne, geological advisor for Occidental, who worked on the team. That, plus the tight deadline, made the assignment “daunting at the beginning. We were trying to figure out the best way to tackle it.”

The immediate task was to find cost-effective ways to revive older wells to generate more cash flow to justify the continued presence of the floating platform at that location. In the process they were expected to create a detailed subsurface analysis to allow a more-informed judgment on the field’s potential and guide any future development.

A solution to that daunting problem arrived with a petroleum engineer who’d been in a group at Anadarko developing digital oilfield technology, Subash Kannan, who is now a program manager at Occidental.

In his previous job, he had been on a team that used a pair of related methods developed to speed software development such as an agile scrum—very Silicon Valley sorts of names.

Scrum referred to a way for a group to push ahead effectively, like a scrum in rugby where teammates need to fight together to grab the ball. Agile referred to a work-planning process that allowed them to adapt to the changing challenges ahead.

Underlying the clever labels were mainstays of project management—regular meetings, goal setting, database building, and progress reports provided to management.

Each workday, the three team members would hold a scrum meeting online from their home offices during the COVID-19 pandemic. The key item on the agenda was setting their minimum viable product. Jeansonne described that as the “deliverable essential for a given team member to reach their next day’s goal.”

That required recognizing each other’s needs, to ensure the work they did allowed the others to keeping moving ahead.

For example, the geophysicist interpreting the seismic data needed the well log analysis from the geologist to accurately identify the rock in the layers mapped by the seismic signals. And the geologist needed the seismic interpretation to define the stratigraphic outlines of the producing rock in the area where they are both working.

In a larger sense, the minimum viable product is a simple working version of an evolving product.

Rather than building a version of the final product they created a series of rough, workable versions to ensure each one worked. And that allowed them to change the final product as needed. Or to use another favorite bit of startup jargon—to pivot.

On that project, they needed to pivot when oil prices went down then back up again, when Hurricane Delta battered the central Gulf of Mexico, and when new technology became available to lower the cost of well work.

Along the way there were weekly update meetings with Work and monthly reports to senior management, which were used to track their progress and sell their evolving ideas for adding production.

Along the way, they were building a detailed database that filled gaps in the subsurface record which had developed over time.

The final plan offered nine ways to add production, which proposed recompleting two wells; three wells with a sidetrack and a recompletion; and four wells where remediation would be sufficient.

And it was all completed on time. “Most projects get pushed to right, but this project was executed on time,” Jeansonne said.

For Further Reading

SPE 210199 Agile–Scrum-Based Approach To Identify and Evaluate Opportunities in a Mature Field by Subash Kannan, Natasha Jeansonne, and David Work, Occidental.

SPE 210288 Finding the Right Concept via a Decision Quality Framework With Rapid Generation of Multiple Deepwater Conceptual Alternatives by Y. Zeng, S. Ryu, C.G. Chaney, ExxonMobil Upstream Research Company; S. Kim, Strategic Decisions Group; L.Basilio, Deep Seed Solutions; and J.E. Bickel, University of Texas at Austin.

OTC 32122 Maximizing Value From Mature Assets in Deepwater Gulf of Mexico by Clay Thompson, Manoj Jegannathan, and Natasha Jeansonne, Occidental Petroleum Corp.