As operators produce more opportunity crude oils, oils that provide a higher refining margin relative to other crudes, dehydration of the oil becomes more difficult. Physical properties of the crude oil, such as API gravity, oil viscosity, and water density, determine the challenges and drive the selection of technologies to be used for effective dehydration.

Opportunity crude oils are generally heavy, described as crude oils with API gravities of approximately 20 or less. Very heavy oil is defined as below 14°API, and extra heavy oil is 11°API and below. Known problematic crude oils include Venezuelan Merey (16°API), Mexican Maya (21°API), and Doba (21°API), produced in Chad.

Characteristics of the heavy crude oils that contribute to difficulty in dehydration include reduced oil/water density differences that decrease the forces needed for separation of water droplets, higher crude oil viscosity, and smaller water droplets resulting from heavy crude oil production techniques.

To dehydrate crude oils with high viscosities, the dehydration treaters must be larger than those used for lower-viscosity oils or the temperature must be increased to lower the viscosity to achieve effective dehydration. However, there is an upper limit of approximately 300°F for most dehydration processes.

Higher operating temperatures require increased size of treater power units. Larger supply systems and substations are required to provide the power to these units. A disadvantage to this approach is that the increased power results in electrical current that heats the crude oil and causes other issues.

Electrostatic Technologies Used in Treaters

Typically, crude oil dehydration treaters use retention times, heat, and alternating current (AC) electrostatic technology to treat the oil. Paper SPE 156299 described methods of enhancing the electrical field in bulk oil treaters by the use of combined AC and direct current (DC) electrostatic technologies.

Crude oil conductivity affects the electrostatic fields inside the treaters. If the crude oil conductivity is very low, the electrostatic charge has difficulty reaching the dispersed water droplets. If conductivity is very high, some of the electrostatic charge may dissipate into the crude oil and never reach the water droplets.

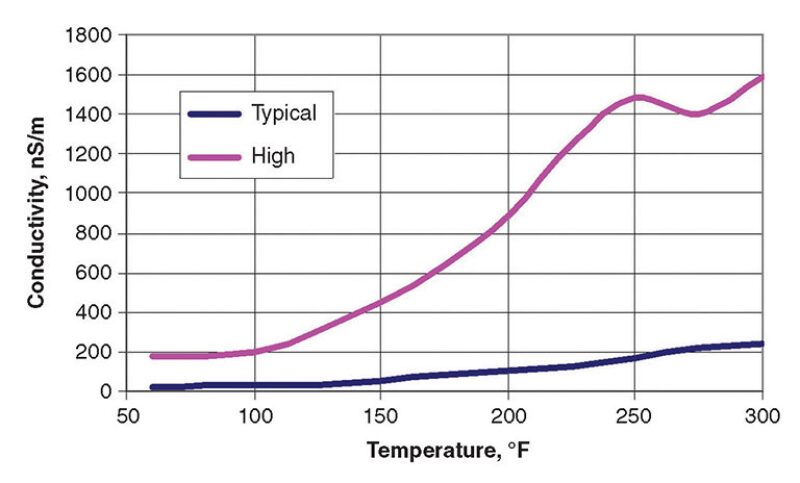

The process temperature in the crude oil treater affects the conductivity of the crude oil (Fig. 1). The crude oil conductivity can increase several times from ambient temperature to process temperature in the treater. The effect of increased crude oil conductivity in an AC treater is a decreased electrostatic field, leading to less effective dehydration because the lower voltage fields cannot reach the small water droplets.

Coalescence of water droplets dispersed in crude oil occurs when the droplets collide with enough energy to overcome barriers to coalescence, such as surface films adsorbed on the droplet’s surface, dispersion of fines around the droplets, and interfacial tension.

Electrostatic fields generate forces that can create conditions for improved coalescence of water droplets, resulting in improved separation of water from the crude oil.

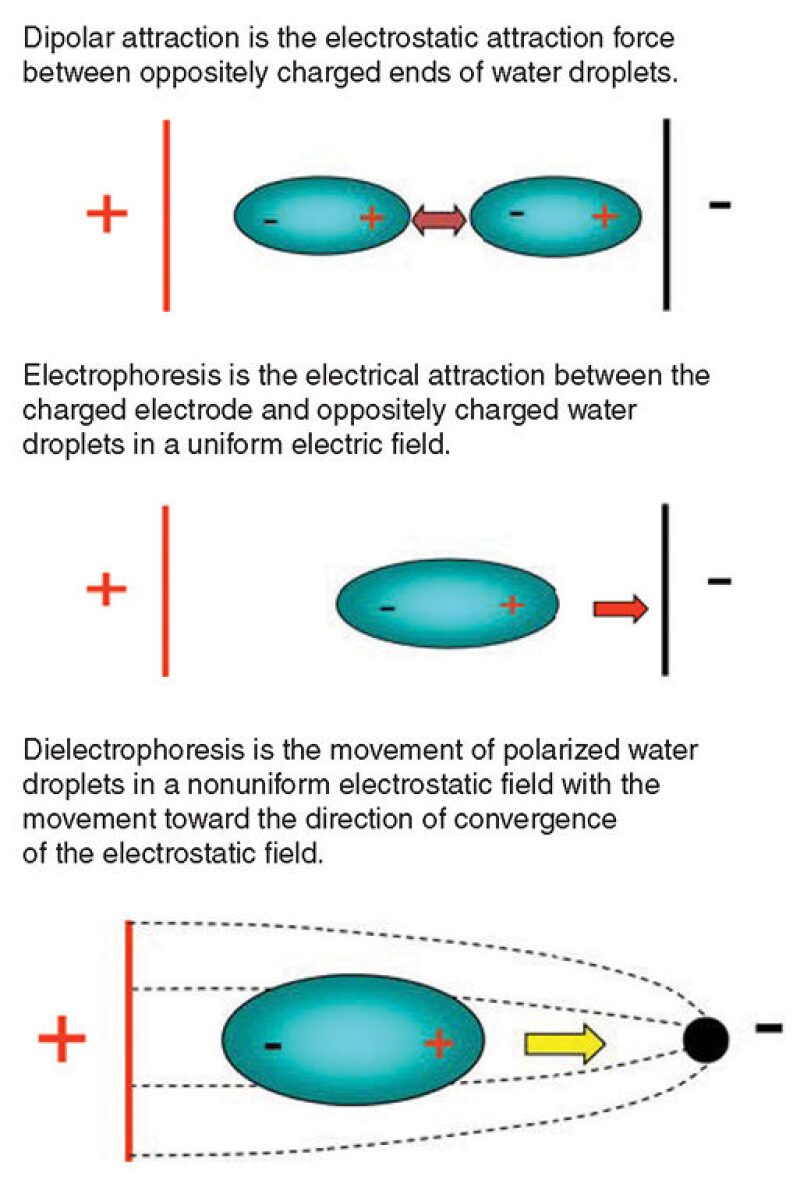

Paper SPE 156299 described three types of primary electrostatic forces (Fig. 2).

Dipolar forces result in the water molecules aligning themselves in an electrostatic field. A water droplet made up of such aligned molecules is polarized with a positive charge on one end and a negative charge on the other end. Polarized water droplets are attracted by other water droplets.

Dipolar attraction is effective for high-water-cut emulsions because the water droplets are larger and more closely spaced. When water droplets are smaller, as in a low-water-cut emulsion, dipolar attraction is less effective because the water droplets are smaller and farther apart.

Electrophoresis moves water droplets horizontally between electrode plates in a uniform DC electrostatic field. With a force of up to four orders of magnitude larger than dipolar attraction, the water droplets collide more frequently.

Dielectrophoresis, the weakest of the three electrostatic forces, is approximately half the strength of the dipolar attraction force. Polarized water droplets move in a nonuniform electrostatic field toward the direction of convergence of the electrostatic field.

Electrical Field Enhancement

AC crude dehydration technology applies an alternating electric field at 50 to 60 Hz to the emulsion, causing the water droplets to deform because of dipolar attraction force. The attraction force between oppositely charged ends of the water droplets speeds up their coalescence.

Treaters using AC fields are effective for bulk water removal, but their performance suffers when lower water cuts are processed. The lower water cut means the water droplets are farther apart, which weakens their dipolar attraction.

DC fields use electrophoresis to enhance water droplet collision rates and promote coalescence. Because the application of a DC field to an emulsion with significant water content results in electro-corrosion, the method is limited to treaters used in refined products.

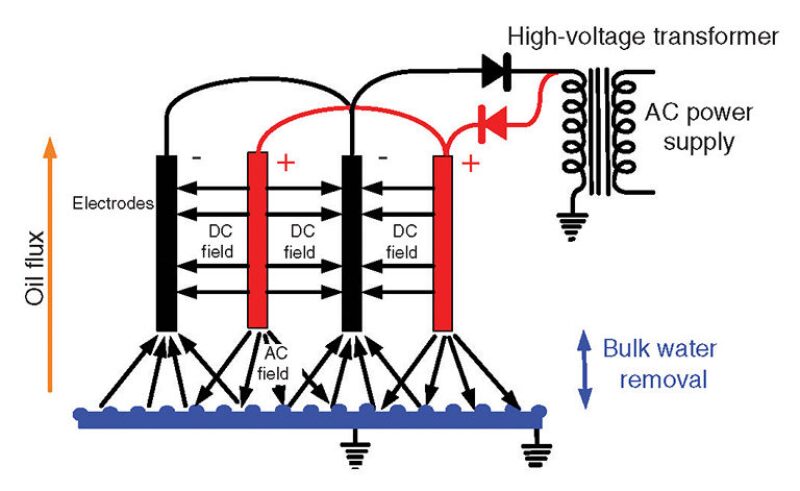

Dual polarity technology (Fig. 3) applies a weak AC field to remove bulk water, followed by a stronger DC field to remove remnant water droplets. The potential for electro-corrosion is eliminated because the DC field exists only between the electrode plates

In the DC field, the water droplets acquire a charge and are accelerated to the electrode of opposite polarity. The droplet then acquires the charge of that electrode and is accelerated back to the opposite electrode. The droplets’ movement in the DC field is mainly because of electrophoresis. The AC field’s dipolar forces aid in deforming the droplets. As the droplets collide, they become larger and separate out of the DC field, settling down to the separated brine phase in the bottom of the treater.

The most recently developed of the enhanced electrostatic field technologies is dual frequency. The dual frequency technology was developed by Cameron; the first patent was issued in 2004, Gary Sams, managing director of research and development at Cameron Process Systems, said.

In AC/DC treatment of crude oils with high conductivity, one set of electrode plates experiences charge decay while the alternate set of plates is being charged. The decay can result in the loss of the DC field. To minimize this effect, the time between charges must be decreased by increasing the frequency of the power source.

The DC field in a treater can be strengthened by replenishing the voltage on the electrodes at a faster rate. Dual frequency technology restores voltages on the electrodes at frequencies of 800 to 1,600 Hz compared to 50 to 60 Hz for a traditional AC system. As a result, “the benefit of the DC field is regained in high-conductivity crude oils,” Sams said.

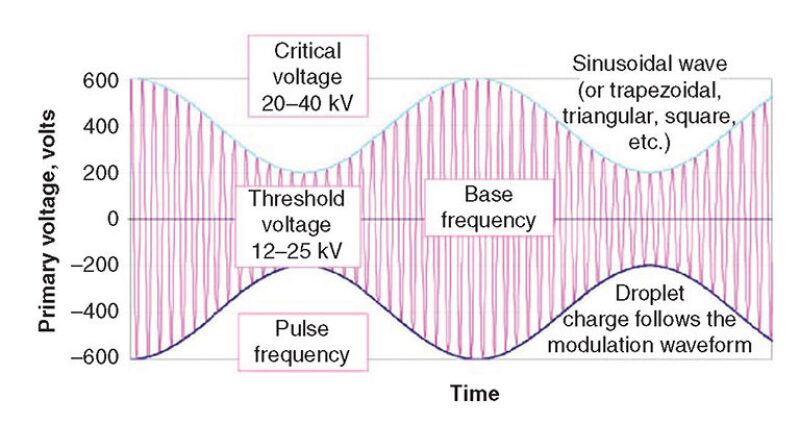

The low interfacial tension of many crude oils can be used to promote droplet coalescence by energizing the water droplet surface. Modulating the power at a frequency close to the resonant frequency of the dispersed water droplets can achieve this.

The frequency of the power supply (base frequency) is set to a value high enough to minimize field decay and is modulated (pulse frequency) at a rate sufficient to energize the water droplet surfaces. The high sustained field strength energizes the droplets so that they readily coalesce.

Fig. 4 illustrates the amplitude modulation of the base frequency possible with this technology. The bimodal frequency modulation in the dual frequency system uses the same electrode configuration as that used in the dual polarity technology.

Sams said that, for retrofitting a dual polarity unit to a dual frequency unit, the only physical changes required are the power unit and the electronic control system for adjusting the base frequency and modulating the DC field.

He said that there are more than 50 installations of the dual frequency technology worldwide, representing more than 100 transformers. “Some operators using the dual polarity technology have pushed it beyond its capacities or their oil proved to be more difficult than they expected it to be. Following replacement of the transformers at the existing vessel to convert to the dual frequency technology, operators typically see a performance benefit. They’re back to spec and can potentially push more crude.”

Process tests performed at the Cameron Technology Center in Houston verified that crude oil dehydration capacity (flux) can be improved by using AC/DC technologies instead of conventional AC technology.

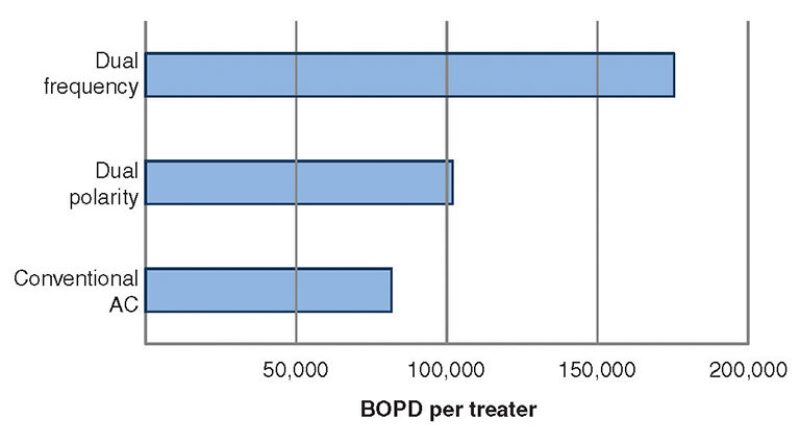

Paper SPE 156299 cited improvements of flux rate of 25% volume/volume by using dual polarity technology, and 125% volume/volume by using dual frequency technology.

Fig. 5 shows the dehydration capacities for three different treaters with identical size but using different electrostatic technologies (conventional AC, dual polarity technology, and dual frequency technology).

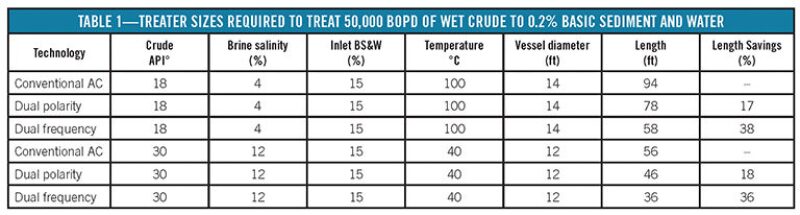

Table 1 shows treater size comparisons using the three electrostatic technologies on 30°API crude oil with 12% salinity formation water and 18°API crude oil with 4% salinity formation water at 50,000 BOPD, 0.2% basic sediment and water.

Besides requiring a smaller footprint, the use of shorter treaters on floating production systems is that trim issues with the floater will have less of a negative effect on the treater level control system. With longer treaters containing level sensors in one end of the treater, the effect of a 1° trim on the floater can push the oil/water interface outside the measuring range of the level sensor, requiring the operator to use manual level control of the treater interface.

Smaller treater size is also important for lower installation cost and projects with shipment size restrictions.

Implementation of Dual Frequency Technology

Operators of the dual frequency technology require initial training. “Once the technology is tuned and demonstrating that the parameters are operating successfully on the crude being processed, the parameters really don’t need to be adjusted again,” Sams said. “The operators need to understand that they shouldn’t be tweaking knobs for the sake of tweaking knobs, because that will get the process out of sync quickly.”

“Operators can also be reticent to make adjustments to the technology until they gain an understanding of what it can do for them. Once they have that understanding and realize that they have another tool available to them besides chemistries, temperatures, and reduction of flow rates, they realize they now have a means to tune their operations at a fairly modest cost. They are no longer incurring the same costs for chemistries or heating, and they’re not losing production,” he said.

For Further Reading

SPE 156299 Benefits of Using Advanced Electrostatic Fields in Crude Oil Dehydrators and Desalters by Erik Sellman, Gary W. Sams, and S. Pavan Kumar B. Mandewalkar, Cameron Process Systems.

OTC 23200 Field Implementation of New Electrostatic Treating Technology by John M. Walsh, Shell International, Gary Sams and Joseph Lee, Cameron.