Approach Resources Inc. is an independent oil and natural gas company headquartered in Fort Worth, Texas. The company focuses on exploring and developing unconventional oil and gas reservoirs.

Founded in 2002, Approach’s core operating area is in the Permian Basin in west Texas, where it has drilled more than 695 wells since 2004. The company targets multiple oil and liquids-rich formations in the Permian Basin, and operates more than 165,700 gross acres.

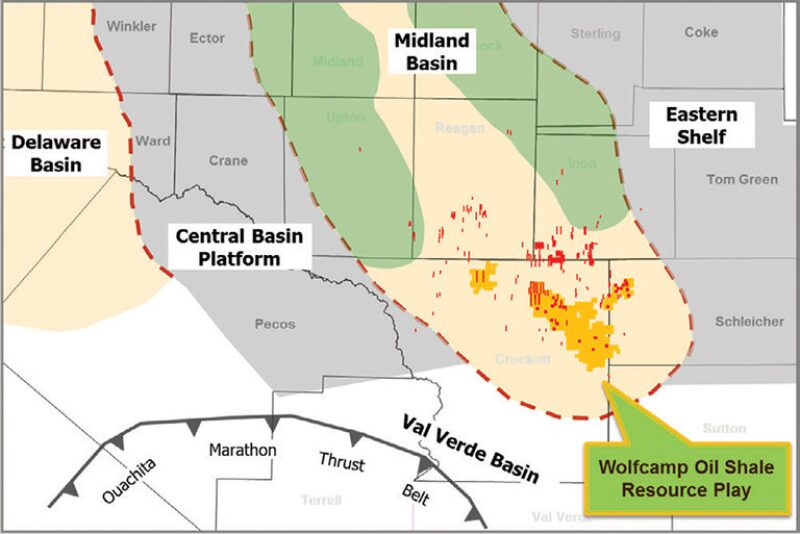

The Emerging Wolfcamp

According to Yang, “an evaluation program was launched in 2009 to see if there was oil and gas in the shallower formation.” The company worked with image logs, cores, 3D seismic, and detailed petrophysical data for about a year and determined the Wolfcamp had a significant amount of oil and gas (Fig. 3).

“We determined there was approximately 118 million BOE per 640-acre section,” said Yang. “This was surprising to us.”

He said the company’s team has experience working in different shales, such as the Bakken and Eagle Ford. “These are very good shales,” he said. “But the in-place volumes are not close to what we were seeing for the Wolfcamp. We thought we’d made a mistake in the calculation for oil-in-place for the Wolfcamp shale.”

However, he pointed out, “We have a very thick column—more than 1,000 ft and in some places as much as 1,200 ft. The column height is what makes the area so prolific.” The Clear Fork adds additional oil in place, he said.

“We began to launch a test program,” said Yang, “whereby existing wellbores completed for the Canyon, Strawn, and Ellenberger would be recompleted targeting the Wolfcamp formation. We would come up hole, perforate, and hydraulically fracture. The results were encouraging.”

Working Up to Development

Beginning in 2011, the company started drilling horizontal wells—new wells, new drilling. Approach initially hydraulically fractured the wells with gel. The results, he said, were not spectacular, but encouraging—in the range of 170 BOE to 300 BOE/D. “We then changed completion techniques and used slickwater fracturing instead,” he explained. “The results improved to between more than 500 BOE/D and more than 1,300 BOE/D.”

Now Approach is forecasting 450,000 BOE for the life of the wells, with a greater than 30% to as much as 50% rate of return.

“Approach has gone from the idea stage to the data collection stage to a pilot program,” said Yang. “Now we’re beginning the development stage.”

The company is actually going to drill multiple stacked horizontals. Right now, according to Yang, the company is sorting out a detailed development plan to optimally develop the area to maximize recovery. “We estimate there’s at least a half a billion BOE recoverable,” said Yang. “And there could be more than that.”

“In 2 to 4 days, we can drill the vertical portion of the horizontal well relatively easily and efficiently,” he said. “So for each stacked horizontal, we’ll drill a new vertical well. For each drilling pad, we’ll drill two to six wells.”

Tricky Geometry

According to Yang, the geometry to figure hole placement, trajectory, depth, and horizontal length is complex. “Take a section that’s 5,280 ft wide (1 sq mile),” he explained, “seven to eight horizontal wellbores could be drilled targeting the Wolfcamp Bench A, Bench B, and Bench C, for around 21 horizontal wellbores in a section, each 7,500 ft long. Then we’ll do 24 to 28 slickwater fracturing stages, with 8 million lb of proppant per well (300,000 to 350,000 lb of proppant per stage) and 210,000 to 250,000 bbl of water.”

Approach works with a small fracturing company called Pumpco, whose headquarters are in Valley View, Texas, and which has operations also in the Bakken and the Marcellus. “Sand supply is not the issue it was a couple of years ago,” he said. “And hydraulic fracturing crews are moving from the Haynesville and Barnett shales to the more liquids-rich plays like the Wolfcamp.”

“We’re drilling 7,500-ft laterals across one-and-a-half sections of 1 sq mile each,” said Yang. “The drilling pad is in the middle of the section. Most of our 148,000 net acres are contiguous, so we’re building in a row across them.”

Going forward, he said, Approach’s objective is to get well costs down to USD 5.5 million per well. Infrastructure will be in place by the end of first quarter 2014, and the company has de-risked 100,000 acres of a total 165,700 gross acres. “In the last couple of years,” he explained, “we have drilled to confirm that the area is commercial, with a nice rate of return. But now we’re in transition to develop it.”

Approach added a third horizontal rig in January to aid in developing the Wolfcamp Bench B in full-scale exploitation mode. The company’s 2013 program is to drill 35 to 40 horizontal Wolfcamp wells, with an average spud-to-total-depth time of 10 to 12 days. Targeting the vertical Clearfork and Wolfcamp, Approach will use one rig to drill 12 vertical wells and plans to recomplete 10 wells.

Control and Success: Improving Economics

In most of its acreage, Approach has a 100% working interest and is the operator. In some of the acreage, according to Yang, “we used to have partners. But we bought them out because we like the high degree of control this gives.”

“We’re a USD-1-billion to USD-1.3-billion company,” he said. “To develop vast acreage, if we choose to accelerate the program we might solicit partners. However, for the time being we have sufficient capital and will be cash-flow positive by late 2014, so we do not have to take a partner.”

Yang said the company has learned a lot over the past 3 to 4 years. “We’re pleasantly surprised by the shale prospect,” he said. “The transition from pilot program to development program went a lot faster than we expected and certainly a lot faster than some other major US plays.”

He pointed out that EOG Resources has a lot of experience in the area and Approach learned a lot from them. Yang cited how to design an effective fracturing program as one area Approach learned from EOG. “EOG has certainly been instrumental in helping develop this play into a commercial play,” he said.

The area used to be gas-producing. “We could truck away the oil in the past,” Yang said. “But now that 58% of production will come from oil for the life of the well, we’re investing in an oil pipeline.”

Approach recently added new gas gathering lines—0.5‑mile, 3.1-mile, 3.5-mile, and 5.5-mile pipelines whereby it can transport Approach gas to a DCP Midstream gas line at better terms. The company is also doing all it can to cut costs. For example, it is transferring water across the field, sourcing it rather than trucking it. And it is reusing wastewater—recycling fracturing water—as well as drilling a saltwater disposal well.

According to the Railroad Commission of Texas, the Permian Basin has produced approximately 30 billion bbl to this point. “What is interesting,” said Yang, “is that we keep finding new ideas, new technologies, new opportunities. From concept to reality, if we only recover a small percentage of the original oil in place—7 or maybe 14 billion bbl—this puts the Wolfcamp into one of the largest plays in the US. As good or better than the Eagle Ford or Bakken.”