-

Thermal imaging helps operators maintain regulatory compliance on methane-emissions requirements. Optical gas imaging technology may be an answer in allowing for faster, more efficient inspections, but there are hurdles to its adoption. How can its widespread use become a reality?

-

The Permian gets the lion’s share of attention when it comes to produced water, but other basins have a need to haul volumes off-site. How has the market changed in these areas recently? Is there a greater enthusiasm for pipelines, and can water midstream thrive?

-

As Permian production ramps up and saltwater disposal well capacity is pushed to its limit, companies see a need to develop collaborative, commercially viable methods of handling produced-water volumes. If reuse remains at its current rate of only 15%, operators could face a $30-billion tab.

-

The $30.5-billion project is expected to produce 18 mtpa of LNG once it starts up; commissioning is expected sometime in the mid-2020s. Canada’s investment includes $160 million to fund energy-efficient turbines, which the government says will minimize greenhouse gas emissions.

-

When surface water is scarce, communities and industries typically turn to groundwater to meet their freshwater needs. A new report from the Groundwater Protection Council indicates that produced water may be a new resource to reduce the use of fresh water for some of those needs.

-

Drones are becoming an important tool for energy companies looking to improve on-site safety and operational efficiencies, and the industry is looking for the best way to maximize their value. What are some the challenges in getting these programs off the ground?

-

The field startup is Hurricane’s first step to actualizing its potentially considerable resources in the UK North Sea. Lancaster is expected to produce an average of 17,000 BOPD by the end of the year.

-

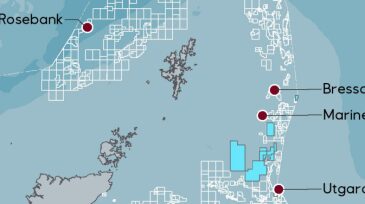

One of the largest pre-sanction fields on the UK Continental Shelf, Rosebank, could significantly bolster the company’s UK portfolio. However, the field’s water depth and harsh environment may run development costs into the multibillion-dollar range.

-

The criticality of above-water riser hull piping requires frequent inspections. Traditional manual inspection methods present safety and efficiency concerns, but work is being done to see if robotic technologies—such as drones and crawlers—can do the job as good as, or even better than, humans.

-

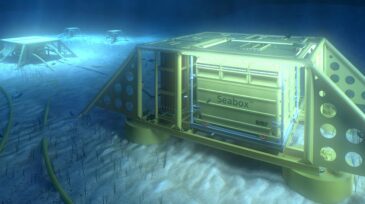

Operators are looking for ways to better handle water coming from subsea wells, which is typically treated at topside facilities. Subsea separation systems are not equipped to discharge water back into the reservoir, so how do companies close the gaps?