Michael Dunkel, vice president for CH2M, believes water management for upstream will transform over the next few years. As shale plays become more established and commodity prices begin to recover, producers are looking for more-efficient and lower-cost water solutions for the longer term. In many cases, more-effective water management is only possible with water infrastructure. Water pipelines and storage facilities bring environmental and sustainability benefits. These water systems allow for the low-cost movement of water and facilitate water reuse, the use of distant nonfresh water sources, and the potential of options for distributing water that must be injected into disposal wells. While there are challenges to building water infrastructure, there are many benefits for the producers and other stakeholders. Water sustainability is an important part of industry’s “license to operate,” and it affects community, regulatory, and investor support.

Dunkel presented his paper “Sustainability Aspects of Water Infrastructure” (SPE-184445) at the 2017 SPE Health, Safety, Environment, and Social Responsibility Conference—North America in New Orleans in April.

Sustainability Aspects of Water Infrastructure

By M.R. Dunkel, CH2M Hill

Abstract

This paper analyzes the benefits of water infrastructure in various onshore regions as it relates to stakeholders and sustainability. Company and stakeholder benefits, impediments, and other trends are discussed, as well as the sustainability aspects of water infrastructure for specific projects. Business sustainability is often defined as managing the triple bottom line—a process by which companies manage their financial, social, and environmental risks, obligations, and opportunities. These are sometimes referred to as profits, people, and planet. (Financial Times 2017.)

The evaluation process included analyzing public disclosures and interviews with oil and gas companies, regulators, service companies, and other stakeholders.

The oil and gas industry continues to move a significant percentage of water by trucks in most US basins. Discussions with leading companies suggest that more infrastructure is being planned by operators and third parties. In many cases, companies are sharing water infrastructure and planning to use infrastructure jointly. The benefits of water infrastructure include lower costs, more flexibility to use multiple sources of water, aggregation of larger volumes of produced water to allow efficient water recycling facilities, reducing community effects by reducing trucks on the road, reducing air emissions, reducing freshwater use, and reducing water disposal by the ability to recycle more effectively. Impediments to building water infrastructure include up-front capital costs, regulatory constraints, obtaining rights of way, and the planning cycle for producing companies. In spite of the impediments, successful infrastructure projects are being planned and developed. In fact, a new trend is showing multicompany projects where several producers may share the infrastructure. Specific projects are highlighted for their sustainability.

What is striking about the different regions of the US is how their water challenges vary. Key limitations and parameters include insufficient source water, limited disposal capacity, regulatory variation, amount of contiguous acreage held by companies, topography, proximity to urban centers, and availability of public roads. Additionally, variations in the targeted formation depth, rock properties, and formation fluids necessitate different hydraulic fracturing practices, which put different constraints on water-management plans. Because of these variations, generalized strategies are not practical; rather, customized solutions are best designed and engineered to meet an area’s unique and specific needs.

History of Water Management for Unconventional Oil and Gas

Unconventional shale development started in the Barnett Shale in the 1980s; however, significant drilling activity did not begin until gas prices increased in the late 1990s. Devon Energy acquired Mitchell Energy in 2002 and established itself as the leading producer from the Barnett Shale. (Railroad Commission of Texas. 2017.) From the early days, water management was normally an afterthought. Typically, water was sourced locally from groundwater or surface sources. Because water volumes were small compared with that used in today’s hydraulic fracturing, there was little or no effect on local resources. Producing companies were still determining technical and economic viability, so little emphasis was placed on long-term planning. As new shale plays were being developed from 2005 and beyond, the priority for operators was to prove a region would produce effectively.

As the US horizontal rig count climbed above 900 for the first time in 2010 (Baker Hughes 2017), sustainability became more of an issue for unconventional development. Stakeholders from Pennsylvania to Texas were increasingly concerned about groundwater contamination or use of source water for hydraulic fracturing. The Environmental Protection Agency (EPA) announced in March 2010 that it would conduct a research study of potential effects of hydraulic fracturing on drinking water resources. (Environmental Protection Agency 2017). In 2011 and 2012, both Texas and Oklahoma experienced extreme drought. (Amico 2012). State officials and stakeholders worried that water use by oil and gas was depleting critical resources. Activist investor organization Ceres published a report in 2014 documenting a link between unconventional development and water stress in parts of the US. (Freyman 2014).

Induced seismicity, often defined as earthquakes caused by human activity, was a developing concern in parts of Ohio, Arkansas, Texas, and Oklahoma. While each situation was unique, regulators and other experts often linked deep well injection of produced water as the likely cause (USGS 2016, Office of the Oklahoma Secretary of Energy and Environment 2017). In the cases of Ohio, Arkansas, and Oklahoma, the regulatory authority reduced water injection to lessen potential effects.

Some regions developed common water management practices to reuse produced water. Water reuse or recycling solves both the sourcing demand and disposal challenge. In recent years, operators in the Marcellus Shale in Pennsylvania and West Virginia pioneered large-scale water recycling technologies—an accomplishment that is good for both the environment and industry (Marcellus Shale Coalition 2017). Other regions, especially in Texas, made strides to use nonfresh water for hydraulic fracturing source water. Some of the successful efforts to manage water more effectively are documented in the Energy Water Initiative (EWI) case studies report of 2015 (Energy Water Initiative 2015). More water management examples are discussed later in this paper.

While oil and gas companies often recognized the need for long-term water considerations, new plays were being developed and the best areas to drill were being continuously refined. The lack of a consistent drilling plan in the “early days” of shale development made water management more challenging and almost impractical. The challenges of implementing water management are discussed later in this paper.

In the second half of 2014, oil prices fell from more than USD 100/bbl to less than USD 50/bbl. The price collapse had an effect on producing companies’ capital budgets overall and funding for water management initiatives.

Objectives and Benefits of Water Infrastructure for Unconventional Plays

The objectives and benefits of water management are the same. Most water managers and most companies are graded on cost-effective drilling and completions. Thus, cost is easily identified as a top priority in water management, especially when commodity prices are low, as they have been since 2014. Comparing different types of cost options can be challenging when one case requires little capital expense (local options) and another requires significant capital (water infrastructure). The dependability of the drilling forecast can become a significant uncertainty for the capital cost case; however, when the long-term drilling plans are relatively firm, water infrastructure can reduce transportation costs and allow reuse to replace local water sourcing and disposal. Having a water plan that keeps costs low is a key sustainability aspect.

Water infrastructure can make distant sourcing options viable and provide flexibility for operations. For example, brackish water is a more sustainable source than fresh water because it generally is unusable for agriculture or drinking without treatment for dissolved solids. Nevertheless, brackish water is often found only in certain areas of a play. Water pipelines conveying brackish water to areas without brackish water save the operator from using potable water. Oil and gas has tapped other nonpotable water sources, including effluent water from municipal water plants. Through an agreement between Pioneer Natural Resources and the city of Odessa, Texas, the energy company installed a water pipeline from the plant to get water closer to the well sites more easily. (Pioneer Natural Resources 2017, Paul 2016).

Water infrastructure allows low-cost aggregation of produced water for more efficient water treatment and distribution near the well site. From the earliest days in unconventional development with horizontal wells and hydraulic fracturing, water reuse was often attempted at a small scale without significant water infrastructure. One of the more notable water recycling efforts started in 2004, when Devon piloted its first water recycling project through a partnership with Calgary-based Fountain Quail Water Management in the Barnett Shale in Texas. Devon and Fountain Quail developed a recycling system that used evaporation and condensation to remove salts and other impurities so water could be reused in other well completion projects (Devon Energy 2017). In spite of Devon’s relatively long-running recycling project in Texas, most water reuse pilots and projects have been short lived because of the challenging economics of the small scale. Water infrastructure can tip the scale toward making reuse viable. The reuse of produced water is the pinnacle of sustainable development because it replaces source water demand and water disposal requirements.

Water hauling with trucks is widely considered the most visible effect of unconventional plays. Lawmakers in Texas have received more feedback from constituents about trucking than any other oil industry activity. Trucking on a large scale can contribute to traffic congestion and can adversely affect smaller roads not designed for heavy trucks. Water pipelines have not been part of the initial development in most unconventional plays for a variety of reasons discussed in the Challenges section of this paper. However, where water pipelines can be justified, the reduction of trucking can be substantial. For a 300,000-bbl well completion, a pipeline transporting water could replace approximately 2,500 truck round-trips to source water and potentially 1,250 truck round-trips to dispose of water over the life of the well. Having water sourcing and disposal pipeline connections could save approximately 113,000 miles of water hauling per well, if the average round-trip is 30 miles. Thus, water pipelines greatly reduce the effect on roads and emissions from hauling water.

Water infrastructure indirectly reduces stakeholder pressure. Stakeholders for an oil and gas producer include investors, regulators, environmental organizations, and citizens in the communities. When water infrastructure is in place, it facilitates many items that are important to these stakeholders.

Stakeholder concerns improved by water infrastructure include the following:

- Reduces long-term water sourcing and disposal costs

- Allows sourcing of nonpotable water that is not near the well site and saves potable water for other stakeholders

- Allows aggregation of water to make reuse and recycling more effective and reduces the need for source water and water disposal

- Reduces water trucked to and from well sites and tank batteries

Challenges to Reuse and Recycling of Produced WaterCost to Transport and Treat Water for Reuse and Recycling. Across many US unconventional plays, produced water from oil and gas operations is disposed into Class II disposal wells. This type of disposal has generally been a safe and low-cost method. Typically, the disposal wells can take large volumes of water, and, usually, minimal transportation costs are incurred because the well is near the producing wells.

For hydraulic fracturing operations to reuse produced water, the water must be transported from the tank batteries where the water is gathered to the new well site. Typically, the produced water must be treated to kill bacteria and reduce suspended solids and any scaling tendencies. Generally, the cost to transport and treat the water for reuse has been higher than the cost to dispose of the water. Thus, produced water reuse has slowly gained adoption in most regions, based on the costs and alternatives.

Because geology varies significantly across the US, some unconventional plays have more limited disposal reservoirs. Other basins may have had modest disposal costs so far, but concerns exist that higher oil prices will increase produced water production and demand for water disposal. Therefore, higher future disposal costs could tip the balance toward increased reuse and recycling.

Legal Uncertainty. In some cases, legal uncertainty in state laws has been an impediment to reuse and recycling. In some states, the ownership of the produced water, if it has value, is uncertain. Historically, the produced water from oil and gas wells has been a burden oil and gas companies must handle. Most commonly, the water has been disposed into deep underground injection wells at a cost to the operating company.

With produced water reuse, the producing company often absorbs new costs related to water treatment and conveyance. Occasionally, one producer may sell treated produced water to another company. Based on the historical and current situation with most unconventional oil and gas plays, the cost to treat and transport the water will far exceed the value of the water sold; the water sold may offset only about 25% of the costs to treat and transport, depending on many factors.

With the emphasis on water reuse, the ownership of the water has been called into question by some surface owners. Surface owners argue that, because most oil and gas leases do not include produced water, the value from selling produced water should be shared with them. Oil and gas companies, on the other hand, feel the value from the sale of water will not cover the cost of treating and transporting the water and, therefore, revenue sharing with the surface owner does not make sense. This is amplified by the fact that the surface owner does not have an obligation to pay for produced water disposal.

Regulatory and legal clarity is needed in some states so that this issue does not slow water reuse. Another legal uncertainty in some states is whether there can be a clear custody transfer if water ownership occurs in the reuse process. As produced water reuse increases, commercial water treatment facilities and their associated water pipelines are likely to become more common. It is important to have a clear legal custody and liability transfer to the commercial operator of the water infrastructure. If oil companies believe they risk being sued over a spill by the commercial plant, it would be a challenge to move ahead with such a commercial model; nevertheless, this approach is often the most effective method for multiple producing companies to operate in a given area, because overlapping water infrastructure operated by different producers is not practical.

Therefore, laws that support the legal transfer of custody of the water and the associated liability to the commercial water system operator would reduce the uncertainty of this issue. Some states have passed statutes to clarify that produced water ownership and liability can be passed to another company.

A third legal issue regarding custody of water relates to the legal classification of produced water if it is treated and transferred to another beneficial user. If desalinated produced water is transferred to a power plant, some uncertainty exists as to whether the power plant’s current permits need to be updated. In some states, the plant’s existing permits would apply and new permits or amendments are not needed. (Note: The power plant would still need to meet all of its existing discharge criteria.) Some experts are less confident that the treated produced water loses its classification when it is transferred to another user. Oil and gas producers want regulatory certainty before transferring water for beneficial reuse.

State Regulatory Challenges. As produced water reuse has evolved over the years, states’ regulations are slowly catching up to help promote environmentally sound recycling; but, unfortunately, some state regulations are still a major impediment to allowing producers to reuse produce water.

One success story occurred several years ago. The Texas Railroad Commission, the oil and gas regulator in Texas, took action allowing produced water impoundments to be permissible by rule, overriding the prior process, which required a long approval time and failed to meet the producer’s needs. The new rule allows produced water to be stored in impoundments if it meets certain criteria, and no waiting period is required to obtain a permit. Generally, impoundments are recognized as lower cost than alternatives for longer-term projects.

Other regulatory challenges affecting reuse include the need to have a recycling permit for each project and the need to track individual barrels of water.

Right-of-Way and Landowner Negotiations. Another significant and often-mentioned challenge to water reuse and recycling is right of way (ROW). Water pipelines and impoundments need authorization from surface landowners. Companies installing water infrastructure often must negotiate with numerous landowners and payments for the ROWs, which can be a time consuming and complicated. Frequently, producers’ lease agreements dictate that water must be sourced from the surface owner, with payment accordingly. Surface owners may capitalize on this economic disincentive to reuse produced water, greatly limiting the producing company’s economic options.

Federal Rules for Discharge to US Waters. Federal rules allow produced water to be treated and discharged to waterways west of the 98th meridian. National Pollutant Discharge Elimination System (NPDES) permits have been obtained from the EPA, or states granted jurisdiction, in a small number of cases for highly treated oil and gas produced water. The NPDES permits could be important in specific cases or in special economic cycles within the oil sector. If oil and gas were reusing a high percentage of produced water in the future and oil prices dropped substantially, the hydraulic fracturing reuse would diminish because of the lack of well completions, and the produced water would need an outlet. If disposal continues to be limited in a region, this sudden reduction in reuse could create an equally urgent need for NPDES permits to discharge water. The problem is that the current approval cycle for a NPDES permit is much longer than the typical time it takes for oil prices to drop and drilling to stop. Thus, shorter approval times or an easier process for obtaining a contingent permit that might be needed in the future are necessary.

Trends in Water Management

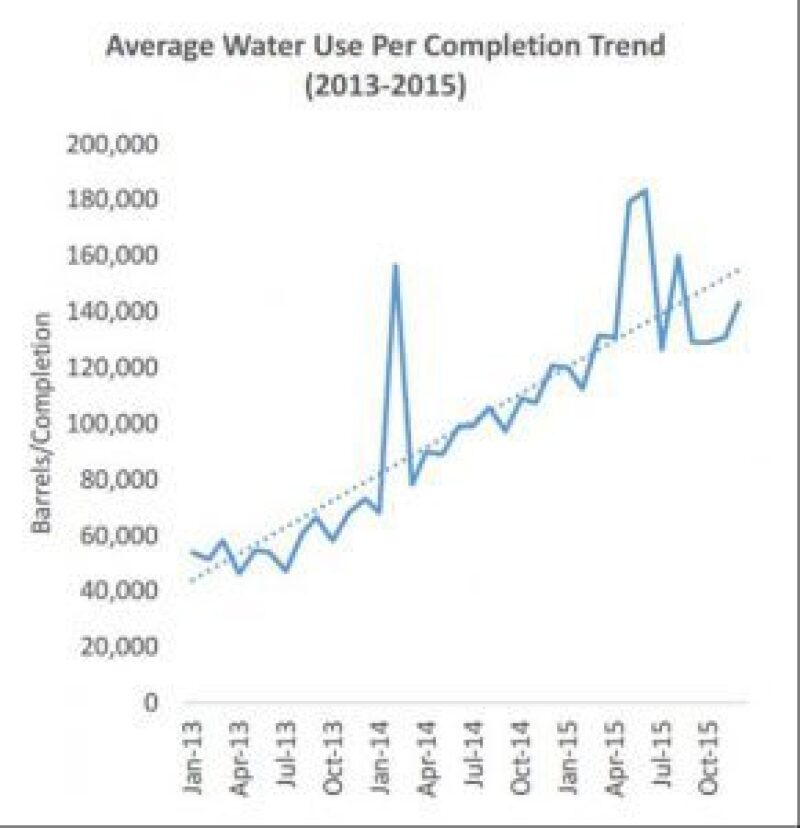

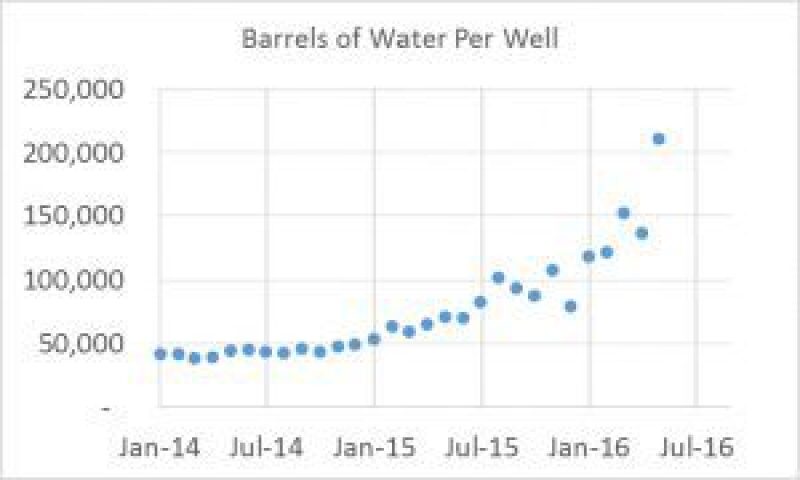

According to public records, such as those found at FracFocus (www.fracfocus.org), companies are using more water per well. The reasons for higher water use per well are longer laterals and more water used per foot. The additional water and proppant are providing higher expected ultimate recoveries than earlier wells. The trend of using more water per well potentially will put more stress on available water sources, creating a sustainability challenge. Water reuse could take pressure off the water sourced from surface and aquifers. Fig. 1 shows the water used per well in the Permian Basin (including vertical and horizontal hydraulic fractured wells). Fig. 2 uses FracFocus data for Oklahoma, showing a similar trend as the Permian Basin—progressively increasing water per well.

|

|

Low-capital-expense water infrastructure projects that reduce costs and have a short economic payout are another result of the low-oil-price environment. This trend has been observed when companies replace trucking of produced water with pipeline connections to a disposal well. The pipeline capital replaces the less-efficient operating costs of trucking the water. In some cases, producers are building the connecting lines to their company-operated disposal wells, and, in other cases, a third-party disposal well operator pays for the line to connect a producing company’s tank battery or wells.

Because capital budgets have been greatly reduced in recent years because of lower oil prices, few large-scale infrastructure projects have been constructed. Numerous companies are evaluating and planning larger-scale infrastructure for future development that will come with higher oil prices. The planned infrastructure may be primarily for a single company, but, increasingly, companies are evaluating how to share water infrastructure. The infrastructure allows aggregated volumes to produce economics of scale that reduce the conveyance cost and treatment costs per barrel.

Basin Comparison of Water Challenges

The various unconventional plays across the US have varying water practices and challenges based on the following:

- Amount of easily accessible source water

- Differences in geology for disposal wells

- Terrain differences affecting ease of pipeline installations

- Regulatory differences

- Amount of produced water relative to the water volume used in completions

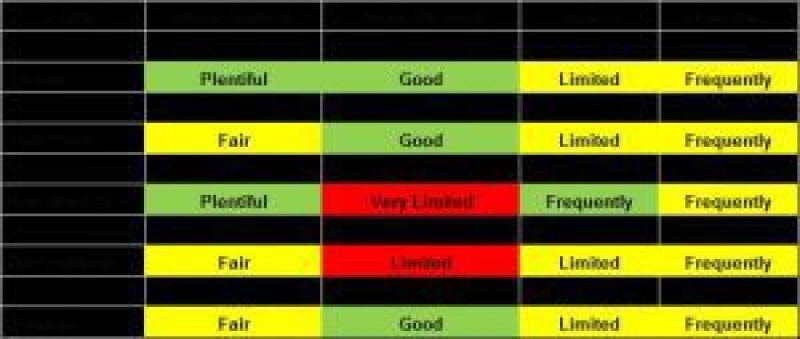

Table 1 is a qualitative comparison of water challenges across several oil and gas basins.

Water infrastructure that allows more water reuse has the sustainable effects of reducing the source water needed, reducing demands for water disposal, and reducing the need for truck transport.

Examples of Infrastructure and Planned Infrastructure

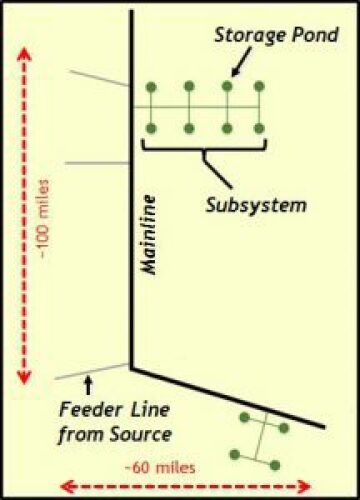

Pioneer Natural Resources, with the majority of its acreage in several counties in the Midland Basin, is using its dominant position to plan efficient water infrastructure. Pioneer has commenced construction on a state-of-the-art water sourcing and distribution system in West Texas. By flowing sourced water through a pipeline system, Pioneer will reduce the amount of truck traffic on county and state roads, while minimizing transportation costs.

When completed, the pipeline network will run approximately 100 miles north/south across Pioneer’s acreage, using 30- to 36-in.-diameter pipe (Fig. 3). The system will have feeder lines that connect to nonpotable water sources, such as contracted municipal wastewater plants.

Construction is expected to continue until 2019 in a phased approach. The system will consist of up to 20 water subsystems branched from the mainline, connecting 125 to 150 strategically placed, double-lined storage ponds that will support hydraulic fracturing operations and recycling efforts in the Midland Basin (Fig. 4).

Pioneer has committed to purchasing 391 million bbl from the city of Odessa over the next 11 years and expects to save approximately USD 100,000 per well (McEwen 2016, Pioneer Natural Resources 2016). In December 2016, Pioneer announced an agreement that will provide USD 110 million in upgrades to the water treatment plant in Midland, Texas. In return, Midland will provide Pioneer reclaimed wastewater for reuse. The water will be transported through Pioneer’s water distribution system in the Midland Basin and used for hydraulic fracturing. Pioneer is also using the existing water network to move brackish groundwater to well sites and plans to use the system increasingly for produced water reuse.

Oklahoma has much more fractionated mineral interests compared with the key four counties where Pioneer is planning its infrastructure. In fact, most US unconventional plays have interspersed acreage ownership, making it difficult for one company to plan a large infrastructure project for water. The Oklahoma oil and gas regulator, the Oklahoma Corporation Commission, has mandated reduced water disposal in key areas in 2015 and 2016 based on seismicity that has been linked to produced water injection (Wethe and Tobbin 2016). Oklahoma’s governor appointed a committee under the Oklahoma Water Resources Board to collaborate and find ways to promote produced water reuse and recycling (Oklahoma Water Resources Board 2017). Water infrastructure is expected to be an important component, facilitating the low-cost conveyance of water from where it is produced to where it can be reused.

Antero Resources announced plans to build a large water treatment facility in West Virginia (Antero Resources 2016) (Fig. 5). Veolia will design, build, operate, and maintain a 60,000 B/D advanced wastewater treatment facility under a turnkey contract for Antero in Doddridge County, West Virginia. Antero will own the USD-275-million treatment complex, which is expected to take 2 years to build. The complex will allow Antero to treat and reuse produced water rather than permanently dispose of the water in injection wells. The treatment facility will save Antero approximately USD 150,000/well on future completion costs. Combined with Antero’s existing freshwater pipeline distribution system, the advanced wastewater treatment complex creates environmentally conscious water management. Once fully operational, the facility will, on average, reduce water truck travel by more than 10 million miles annually. This nearly 50% reduction in water-related truck travel not only further reduces roadway effects but also will cut greenhouse gas emissions by an average of more than 30,000 t/a. Approximately 95% of Antero’s water will be treated at the facility, virtually eliminating the need for wastewater disposal wells. The facility will provide an additional freshwater supply of 41,000 B/D (1.7 million gal/D), which will positively offset withdrawals from West Virginia’s water resources.

Vision for Water Infrastructure Buildout

In the short history of US unconventional oil and gas development, water infrastructure and water planning have been relatively slow to develop for a variety of reasons. Chief among these reasons is the unpredictability of future drilling locations because of rapidly developing technologies. As unconventional oil and gas development evolves and more predictable planning takes place, water infrastructure becomes easier to justify and develop. Additionally, as industry demand for source water and disposal increases, water infrastructure will be a key part of the solution to allow water reuse and flexible water sourcing.

A model is developing where the most economically viable core of unconventional plays are able to justify and develop the initial water infrastructure. Over time, water pipeline additions will be added, often connecting to the initial pipelines. Where ownership is fractionated, multioperator cooperatives or third-party arrangements serving multiple operators could achieve similar sustainability and cost benefits but would bring additional commercial, water-rights, and environmental-liability challenges that framework to address is still developing.

The sustainability aspects of water infrastructure for unconventional oil and gas development are many. Over the next several decades, water pipelines are expected to be built out progressively, driven predominately by cost reduction and sustainability of sourcing and disposal of water.

References

Amico, C. 2012. Dried Out—Confronting the Texas Drought. StateImpact Texas, 5 June 2012, https://stateimpact.npr.org/texas/drought (accessed 9 January 2017).

Antero Resources. 2016. Antero Announces 60,000 Barrel per Day Advanced Wastewater Treatment Complex. http://investors.anteroresources.com/investors-relations/press-releases/press-release-details/2015/Antero-Announces-60000-Barrel-per-Day-Advanced-Wastewater-Treatment-Complex/default.aspx (accessed 9 January 2017).

Baker Hughes. 2017. North America Rig Count. http://phx.corporate-ir.net/phoenix.zhtml?c=79687&p=irol-reportsother (accessed 9 January 2017).

Freyman, M. 2014. Hydraulic Fracturing and Water Stress: Water Demand by the Numbers. Ceres, February 2014, https://www.ceres.org/resources/reports/hydraulic-fracturing-water-stress-water-demand-by-the-numbers/view (accessed 9 January 2017).

Devon Energy. 2017. Water Management a High Priority. August 2014. http://www.devonenergy.com/featured-stories/water-management-a-high-priority (accessed 9 January 2017).

Environmental Protection Agency. 2017. EPA’s Study of Hydraulic Fracturing for Oil and Gas and Its Potential Impact on Drinking Water Resources. https://www.epa.gov/hfstudy (accessed 9 January 2017).

Energy Water Initiative. 2015. US Onshore Unconventional Exploration and Production Water Management Case Studies. Oklahoma Water Resources Board, http://www.owrb.ok.gov/2060/pwwg.php (accessed 9 January 2017).

Financial Times. 2017. Definition of Business Sustainability. http://lexicon.ft.com/Term?term=business-sustainability (accessed 9 January 2017).

Marcellus Shale Coalition. 2017. Water. http://marcelluscoalition.org/marcellus-shale/production-processes/water (accessed 9 January 2017).

McEwen, M. 2016. Pioneer Natural Resources Honored for Water Deals with Odessa, Midland. Midland Reporter Telegram, http://www.mrt.com/business/oil/article/Pioneer-Natural-Resources-honored-for-water-deals-10591666.php (accessed 9 January 2017).

Paul, C. 2016. Pioneer Taps City Wastewater. Odessa American,http://www.oaoa.com/news/government/city_of_odessa/article_3477e9ae-c04b-11e5-87f5-d3dfa6dd7a5a.html (accessed 9 January 2017).

Office of the Oklahoma Secretary of Energy and Environment. 2017. Earthquakes in Oklahoma FAQs. https://earthquakes.ok.gov/faqs (accessed 9 January 2017).

Oklahoma Water Resources Board. 2017. Water for 2060 Produced Water Working Group. http://www.owrb.ok.gov/2060/pwwg.php (accessed 9 January 2017).

Pioneer Natural Resources. 2016. Investor Presentations December 2016. http://investors.pxd.com/phoenix.zhtml?c=90959&p=irol-presentations (accessed 9 January 2017).

Pioneer Natural Resources. 2017. Pioneer Water Management. http://www.pxd.com/operations/water-management (accessed 9 January 2017).

Railroad Commission of Texas. 2017. Barnett Shale Information. http://www.rrc.state.tx.us/oil-gas/major-oil-gas-formations/barnett-shale-information (accessed 9 January 2017).

USGS. 2016. Induced Earthquakes. https://earthquake.usgs.gov/research/induced/myths.php (accessed 9 January 2017).

Wethe, D., and Tobbin, S. 2016. Oklahoma Quake Matches Record Even After Fracking Restricted. Bloomberg,https://www.bloomberg.com/news/articles/2016-09-04/oklahoma-quake-matches-record-even-as-fracking-waste-restricted (accessed 9 January 2017).