Effective heat management is essential in high-enthalpy geothermal drilling, where extreme downhole temperatures (often exceeding 150°C) can compromise tool reliability and operational efficiency. Traditional physics-based models offer accurate downhole temperature (DHT) predictions but are too computationally intensive for real-time use. To address this, a deep-learning framework using a long short-term memory (LSTM) neural network was developed to estimate DHT in real time under varying drilling conditions. This approach provides a fast, reliable alternative to numerical simulations and enables proactive temperature control during both circulation and pump-off phases, ultimately enhancing drilling efficiency and reducing costs.

As geothermal wells are drilled into deeper and hotter formations for commercial power generation, managing DHT becomes increasingly critical. Elevated thermal conditions can lead to tool failure, sensor drift, and reduced drilling performance, significantly increasing operational risk and cost. Thus, real-time DHT prediction enables timely decision-making and the selection of optimal cooling strategies, which eventually avoids drilling problems related to high DHT.

Drilling fluid circulation plays a central role in heat management during drilling operations. While continuous circulation aids cooling, mud pumps are routinely shut down for operational reasons, such as pipe connections (3–5 minutes), topdrive lubrication/repair (15–30 minutes), pump maintenance, or unplanned events such as stuck pipe and trips, which may halt circulation for hours. These pauses often lead to rapid downhole heat buildup, especially in high-temperature reservoirs.

Traditionally, the drilling industry has relied on high-fidelity thermal simulators to predict DHT for the different operational scenarios. Though accurate, these models are too slow for real-time applications. To overcome this limitation, a deep-learning solution is proposed that is capable of capturing full-scale thermal behavior efficiently. Trained on synthetic data derived from validated simulations of FORGE field scenarios, the developed model enables fast, accurate prediction of DHT under a wide range of geothermal drilling conditions. This paper details the model’s development, validation, and operational utility for real-time DHT monitoring in geothermal wells.

Model Development

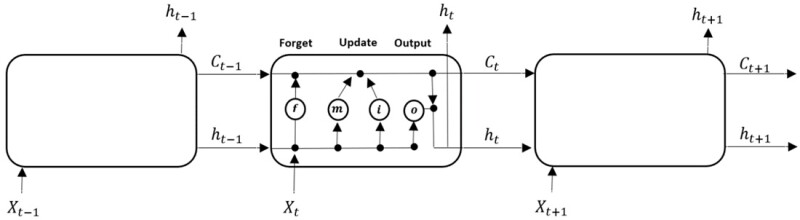

The predictive framework in this study uses LSTM networks, a class of recurrent neural networks (RNNs) designed to capture complex temporal dependencies in time-series data. LSTMs maintain and update internal memory through two key components: the cell state (C) and the hidden state (h). Information flow is regulated through three types of gates (Fig. 1): forget (f), input (i) with the memory cell (m), and output (o). A detailed description of the LSTM architecture and governing equations is available in paper SPE 217749.

A deep LSTM (DLSTM) model was developed and trained on synthetic data generated from a validated thermo-hydraulic simulator representative of FORGE field conditions. The simulator solves transient, one-dimensional conservation equations for mass, momentum, and energy, coupled with auxiliary equations that capture heat transfer and fluid behavior in the wellbore. It includes external heat exchange with the formation, liquid property submodels as functions of pressure and temperature, and a semi-implicit numerical scheme for solving the system. (Details can be found in paper SPE 210306.) Simulation cases covered both circulation and pump-off scenarios across a wide range of operational parameters, including mud flow rate; mud inlet temperature; reservoir in-situ temperature; horizontal lateral length; wellbore size; drillpipe dimensions; mud type, including water-based mud (WBM) and synthetic-based mud (SBM); viscosity; mud weight; and pipe insulation. Over 500 distinct scenarios were generated for model training and evaluation.

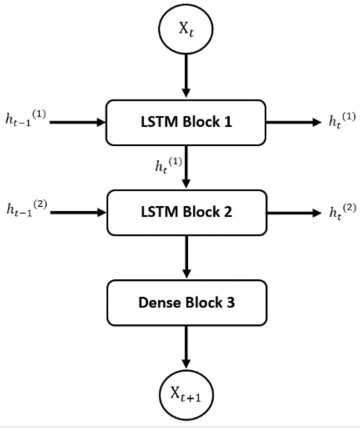

Data preprocessing included an 80:20 split for training and testing, along with normalization by mean removal and unit variance scaling. Model hyperparameters were optimized using Bayesian optimization, which builds a probabilistic model of the objective function based on prior evaluations to efficiently identify promising hyperparameter combinations, significantly reducing tuning time compared with grid or random search methods. A 3-minute lag window (three timesteps) was found optimal for capturing the transient nature of DHT without introducing overestimation. The final DLSTM architecture consisted of two stacked LSTM layers with 506 units each, followed by a dense neural network layer (Fig. 2).

In the DLSTM model, the first LSTM layer computes its hidden state using the current input and the previous hidden state. This output is passed to both the second LSTM layer and the next step. The second layer combines it with its prior hidden state to generate its output. Finally, the stacked LSTM output is combined with the original input features and passed through a dense neural network layer to produce the final DHT prediction. Initially, a high sampling frequency of 0.2 Hz caused overfitting, while lower frequencies missed key temperature behaviors. A sensitivity analysis across multiple sampling rates (0.2, 0.07, 0.03, 0.02, and 0.017 Hz) identified 0.017 Hz as the optimal rate, offering the best trade-off between prediction accuracy and generalization.

Results and Discussion

The DLSTM model was trained and tested on over 150,000 synthetic data points representing a broad range of geothermal drilling conditions. The model consistently demonstrated strong performance, with mean absolute errors (MAE) below 2.5°C and most predictions falling within a 15% accuracy envelope across both training and testing data sets.

To interpret the model’s behavior, Shapley additive explanations (SHAP) analysis was performed. Based on game theory, SHAP assigns important scores to input features, highlighting their contributions to individual predictions. The analysis identified prior DHT values, mud type, and horizontal lateral length as the most influential features, all showing positive correlation with predicted DHT. Additional contributing factors included drillpipe inner diameter, vertical depth, and mud weight. Note that, to handle mud type as a categorical variable, three fluid types were numerically encoded: WBM (1), SBM 80:20 (2), and SBM 90:10 (3). The positive correlation between mud type and DHT is attributed to the reduced heat capacity of SBM compared with WBM, which results in less effective cooling and higher predicted DHT.

In contrast, wellbore hydraulic diameter and fluid viscosity negatively influenced DHT predictions; larger wellbore diameters and higher viscosities generally lowered downhole temperatures. The effects of flow rate and pipe conductivity were dependent on scenario. While higher flow rates and insulated drillpipe typically reduce DHT, they can contribute to thermal buildup in extended horizontal sections because of frictional heating.

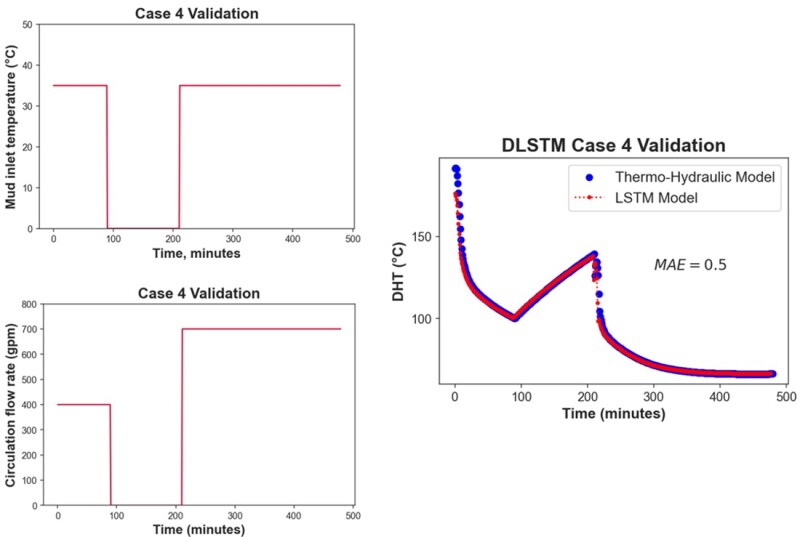

To evaluate the model’s generalizability, four validation cases (unseen during training) were generated using a thermo-hydraulic simulator representative of FORGE field conditions. These scenarios varied in fluid type, well geometry, pipe insulation, and lateral length. Across all cases, the DLSTM model accurately captured the full transient behavior of DHT, maintaining an MAE below 0.8°C. In Case 4, for example, a 1000 m horizontal well targeting a 200°C reservoir was simulated. Fluid was circulated at 400 gal/min for 1.5 hours through a 10.625-in. wellbore using 9 lbm/gal mud (7 cp viscosity) and insulated drillpipe. This was followed by a 2-hour pump-off period, after which circulation resumed at 700 gal/min. As shown in Fig. 3, the DLSTM model closely tracked the numerical model’s transient DHT profile, accurately capturing the sharp temperature rise during pump-off and the subsequent cooling upon circulation with an MAE of just 0.5°C. These results demonstrate the model’s robustness in capturing real-time DHT behavior under diverse geothermal drilling conditions, offering a fast and reliable alternative to traditional numerical simulations. Additional case details are available in paper SPE 217749.

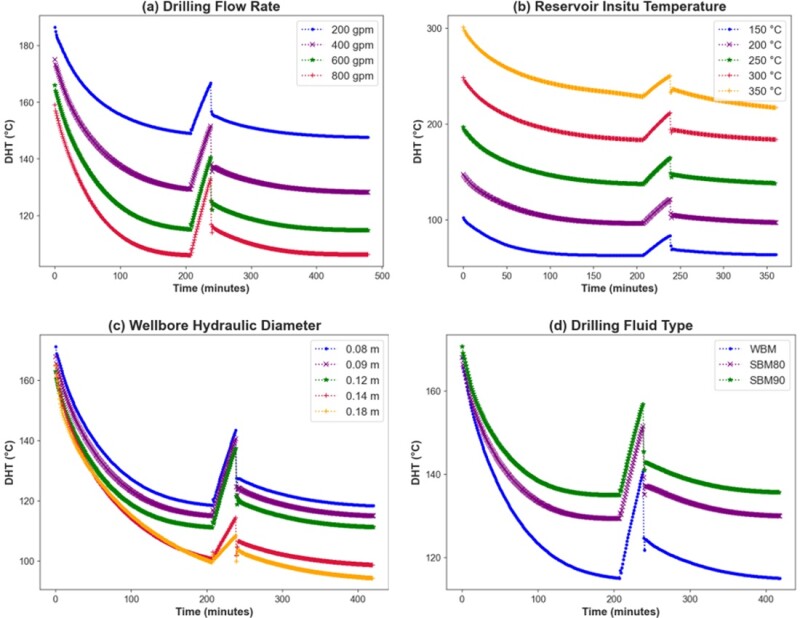

Finally, A parametric analysis was performed using the DLSTM model to evaluate its ability to replicate known thermal management strategies. Key operational parameters included drilling flow rate, reservoir temperature, wellbore hydraulic diameter, and mud type. As shown in Fig. 4, the model confirmed the following established trends:

- Higher flow rates significantly reduce DHT by rapidly displacing hot annular fluid and cooling the near-wellbore region during circulation (Fig. 4a).

- Targeting hotter reservoirs increases DHT because of greater heat flux from the formation (Fig. 4b).

- Larger hydraulic diameters reduce DHT by increasing annular volume and fluid resistance to heat transfer (Fig. 4c).

- WBM outperforms SBM in heat management because of its higher specific heat capacity that reduces heat interactions between the annular drilling mud and the formation (Fig. 4d). SBM refers to synthetic-based fluids with oil/water ratios of 80:20 (SBM80) and 90:10 (SBM90).

Notably, the DLSTM model generates these parametric insights (Fig. 4) in real-time, eliminating the long computational delays associated with physics-based simulators, which often require hours or days, depending on the scenario complexity and available resources. This efficiency makes the DLSTM model a practical and scalable alternative for capturing transient DHT behavior during different operational events. Its speed and accuracy enable continuous DHT monitoring, support the selection of effective cooling strategies, and empower proactive temperature management during geothermal drilling operations.

Conclusion

This study presents a DLSTM-based framework for real-time DHT prediction in geothermal wells. The model enables proactive temperature management and supports the selection of optimal cooling strategies, enhancing drilling efficiency and minimizing the risk of temperature-induced tool failures. Trained on synthetic data, it consistently achieved MAE values below 2.5°C under varied drilling conditions, demonstrating strong generalization and predictive accuracy. Key influencing features included prior DHT values, mud type, and lateral length. The developed DLSTM model offers a fast, scalable alternative to physics-based simulators for real-time geothermal applications.