The industry’s experience thus far drilling offshore the Arctic is a powerful argument to build a new generation of vessels and drilling rigs purpose built for operations in heavy ice. Many of the new exploration concepts that seek to overcome challenges in the Arctic were presented at the recent 2014 Arctic Offshore Technology Conference in Houston. Alexander Brovkin, a facilities and logistics adviser at the Chevron Arctic Center, agrees that while new vessel technology is needed for exploration drilling in the Arctic, first the resource must be proved by the drill bit. “An operator must first have a portfolio of Arctic wells before making a significant capital investment to design or build something new,” he said, adding that companies will be pushed to make decisions soon in order to comply with the terms and deadlines set by their offshore leases.

Following Shell’s recent experiences, Arctic exploration off North America is at the moment paralyzed. Considered to be two of the most promising Arctic areas, development in the Chukchi and Beaufort Seas offshore Alaska has stalled out despite there being dozens of leases in those areas set to expire over the next couple of years.

And after spending billions of dollars on its Arctic drilling program to date, Shell canceled all operations in the area for this year. The decision followed a series of accidents during the company’s Alaskan expeditions that began 2 years ago, one of which involved a drillship running aground, and a United States federal court decision that created uncertainty over the terms of its leases. ConocoPhillips and Statoil followed suit and have indefinitely postponed their Arctic drilling plans off Alaska. However, in the Russian Arctic, ExxonMobil and Rosneft are pressing ahead with a joint venture using conventional semisubmersible technology, which limits their operations to the open water season.

Han Tiebout, manager of product development at the offshore engineering and design firm Gusto MSC, said the offshore industry will be keeping a watchful eye on how the companies perform in the Russian Arctic and to see if they hit their mark with their drilling programs. “Our feeling is that they will have to make a few new discoveries before they start investing in purpose-designed Arctic rigs,” he said. “Only at that time will we know if the Arctic can compete with the other investment opportunities that the operators have, and as we know, the Arctic is not the cheapest of areas to do business in.”

Despite the barriers, the Arctic’s rich reserves have justified continued exploration work. But to enhance the capabilities of the industry beyond what current vessels and rigs offer, Gusto MSC has developed a portfolio of drillship concepts and other vessels designed to allow drilling operations to be carried out for several months at a time, instead of several weeks. The “systems approach” Gusto MSC has devised complements the Arctic drillship, or an Arctic jackup, with a multifunctional vessel capable of well intervention operations to provide backup services to the drillship, such as tophole drilling or emergency well response.

Chevron has too adopted the idea that to access the Arctic efficiently, the challenge must be approached using a series of vessels working together as a system to provide the self-sufficiency and redundancy required for such harsh conditions and remote operations. To assist in the development of Arctic exploration, Chevron is working on its own concept of an Arctic drilling system that includes up to three ice-class support vessels, an ice-class wareship, and an ice-class Arctic drilling rig. Based on estimates, such a system could end up costing approximately USD 2 billion to build and would have a limited operating season dictated by ice conditions.

Ice Dictates Design

To best counter the effects of Arctic sea ice, both Chevron and Gusto MSC have concluded that a ship-shaped drilling rig is superior to a semisubmersible in many ways and is likely to be the design concept of choice in the Arctic going forward. By selecting a ship-shaped design, operators will also have more deck-load capacity than a comparable semisubmersible, which is a critical capability in the Arctic because the unit needs to be as autonomous as possible. Drillships are also capable of mobilizing to and from remote Arctic operating areas under their own power and faster than other drilling platforms. And by using azimuth propellers to pivot, a drillship can orient itself so that the bow faces the direction of oncoming ice floes to reduce the area exposed to impact. “Whereas a semisubmersible is anchor moored and will not weathervane,” Tiebout explained. “Because of all the bracings and columns, [a semisubmersible] will attract more ice loading as the ice gets clogged up in frames above and below the water line,” thus attracting more ice forces.

Drillships normally rely on dynamic positioning thrusters to maintain station, but this may not be the best option in the Arctic because those systems are not designed to compensate for the forces that ice can impose on a vessel. Without the ability to counteract movements caused by ice, the drillship could begin to drift off-site, overstressing and damaging the drilling riser. The passive turret mooring system that Gusto MSC proposes is preset and tensioned up to the expected ice loading forces that the vessel may encounter. This gives the system some flexibility of movement, but within the limits that allow drilling to continue. If the ice forces become too great, then the drillship would be forced to release its turret mooring system to ensure the drilling riser is not compromised. “It would be the same situation as an FPSO (floating, production, storage, and offloading unit) in the Gulf of Mexico (GOM) trying to avoid the extreme forces of a hurricane,” Tiebout said.

Arctic Drill Mode

Gusto MSC’s Arctic drillship hull design is based, among others, on the compact Bully drillship hull designs that it developed for a joint venture between Noble and Shell. While similar in many ways to those rigs, an Arctic version would be significantly larger in order to hold enough stores and supplies to drill two wells before returning to port. And despite the myriad of challenges involved with operating in the Arctic, the drilling operation itself is perhaps one of the least complicated. “The wells in the Arctic are not challenging from a geological standpoint,” Tiebout said, comparing the region to the deepwater reservoirs found in the US GOM or the pre-salt areas offshore Brazil. “People who have drilled [in the Arctic] tell us that the wells are pretty straightforward.”

In shallow water Arctic drilling, operators will be required to use surface blowout preventers (BOPs). Locating the BOP on the drilling floor, as opposed to the seabed, avoids the risk of scouring by slow-moving and deep-gouging icebergs that may move into the area of operation. As an added benefit, Tiebout said that this will give operators much greater access to the BOP for maintenance and more direct control over the pressures inside the well. “Subsea BOP control systems are a major headache for everyone in the drilling industry, because they incur the most downtime on a floating drilling rig,” he said. “Surface BOP drilling, if you talk to the drilling engineers, seems to be a safer option for drilling than with a subsea BOP.”

Capabilities Come at a Cost

The estimated prices for new designs built years in advance are impossible to predict, but in general, such a platform should be expected to cost at least 50% more than a conventional drillship, which can average around USD 600 million per unit. The added expense is not only a result of adding the steel required for a sufficiently high ice classification, but also from the turret mooring system, the ice-worthy azimuth propulsion system, and winterization of the decks that will protect both the crew and equipment from freezing temperatures.

As there have been no such Arctic drillships built to date, Tiebout said that more understanding and research is needed to create regulations concerning the ice loading effects on floating vessels. At present, these standards only apply to fixed leg platforms. Gusto MSC has completed general testing on its Arctic drillship models, but would need more advanced simulations to be carried out if the concept is selected for a specific Arctic area. “There are no two Arctic areas alike, they are all different from an ice point of view,” Tiebout said. “So any development on floaters in the ice needs to be supported by extensive ice model testing.”

Arctic Marine Support

A next generation Arctic drillship would also need to be complemented by a next generation Arctic support fleet. Chevron’s Arctic marine support system encompasses nearly every aspect of a development—except for the drilling—and can be broken down into three categories: ice management, self-reliance in remote areas, and oil spill response. “Everything starts with ice management,” said Brovkin of the Chevron Arctic Center. “You need a vessel capable of icebreaker duty to bring the rig into the area of operations, then to make sure it is protected from the effects of ice—allowing it continuous station keeping while drilling.”

This vessel, called an Arctic multi-support vessel (MSV), serves as the cornerstone of Chevron’s Arctic marine support system. In addition to ice management operations, the other support functions the vessel needs to provide an Arctic drilling rig include resupply, towing, anchor handling, remotely operated vehicle deployment, diving support, and emergency standby duties in case of an evacuation or well control problem. Driving the need for such a vessel is the fact that among the world’s inventory of support vessels, Chevron found that none have been designed to operate in the heaviest of ice conditions with the type of capabilities it is seeking.

Filling this gap in the vessel market will come at a high cost. To be successful, the vessel must marry the capabilities of a typical offshore support vessel with those of an icebreaker, which means adding a thick layer of steel to strengthen the hull against the kinetic punishment endured while sailing through ice, and more horsepower to push through that ice. With an estimated price tag of between USD 180 million and USD 250 million, an Arctic MSV has the potential to be the most expensive support vessel ever built. “The higher capital required to build this vessel, so it can operate in the Arctic, drives the increase in the day rate for this vessel,” Brovkin said.

And to provide an adequate level of reliability, Brovkin thinks that at least two Arctic MSVs are required per drilling rig, and possibly up to three for emergencies. Adding more vessels to the system is one way that Chevron is trying to avoid the “Swiss Army knife effect,” whereby so many capabilities are added to a vessel that its core functions become diluted as a result. “While this vessel will not be charged with each single operation,” Brovkin said, “it needs to be capable of them so the vessels can be interchanged, to provide redundancy.”

Because such a vessel might cost up to a quarter of a billion dollars, Brovkin said this would induce the vessel’s owners to require an operator to agree to a long-term continuous charter for 5 to 10 years. This creates a challenge for operators who must figure out what to do with such an expensive, high ice class vessel for most of the year when the ice is too thick for it to operate. If deployed to a non-Arctic zone, an Arctic MSV’s performance and day rate would not be competitive against conventional support vessels, leaving operators with the choice of cold stacking the vessel or find ways to effectively use it on other projects to mitigate the financial loss.

Remote Operations

Given the remote nature of most Arctic drilling sites, and the hazards of transiting through ice, vessel designers plan to store enough supplies for at least 90 to 120 days. In theory, this would give the drilling flotilla enough time to drill one or two wells at the most.

To provide the highest level of self-sufficiency in the most remote areas of the Arctic, Chevron’s support system includes a high ice class storage vessel, or wareship, to house enough food, water, fuel, and equipment to supply all the vessels in the flotilla and the rig for up to 4 months. “If you are in the open water for only a short period of time, you want to be able to use every single day you have and get as close to 100% productivity while you are there,” Brovkin said. In basic terms, “You do not want to go there and find out that you don’t have the materials or tools to do the job.”

Arctic Spill Control

The last major component to Chevron’s vision of an Arctic support system is well containment and spill response. “From the time of when your accident started, up until the relief well is drilled, you have quite a significant spill going on,” Brovkin said. “So we are saying that we need some kind of mechanism as part of the Arctic system that will stop the flow right away.”

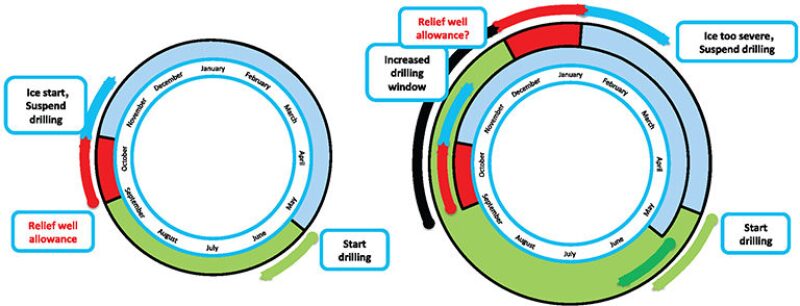

The mechanism might be similar to the capping stack system used to contain oil and gas from the Macondo well that suffered a blowout in the GOM in 2010. In the Canadian Arctic, companies are already required to demonstrate that in case of a blowout, they are capable of drilling and completing a relief well within the same operating season. “This is a very, very challenging requirement,” Brovkin said. “Number one, you have to have another rig that is capable of this operation. Number two, the length of the season may not be long enough to drill two wells.”

Because of this dilemma, there is one school of thought in the offshore industry that said the containment system should remain onshore in standby mode and only be mobilized after an accident has occurred. “But once again, we are operating in very remote areas and the hardware is quite large and heavy,” Brovkin said. “So depending on where you operate, it might take 2 to 3 weeks or more to mobilize it to that area.” Finding such a mobilization time unacceptably long, Chevron’s Arctic solution dictates that a well containment system and response equipment to be stored in-field for deployment by an Arctic MSV.

In the event of a blowout, and no matter how quickly the operator responds, there will be a spill. To respond effectively, the support vessels will potentially be responsible for tracking the spill and tending to it through the winter months using tactics designed specifically for the Arctic.

For Further Reading

OTC 24633 Next Generation to Break the Ice—The Oblique Icebreaker by M. Hovilainen and Arto Uuskallio, et al, Aker Arctic Technology

OTC 24616 A New Jackup Unit Concept to Extend the Arctic Drilling Season by Maria Urycheva and Ove Gudmestad, et al, University of Stavanger

OTC 24632 Increasing Role of Marine Support in Arctic Offshore Exploration Drilling by Don Connelly and Alexander Brovkin, Chevron Canada.

OTC 24667 Results Using Azipod Propulsion in Ice Management Operations by Samuli Hanninen and Torsten Heideman, et al, ABB Marine

SPE 166848 Development of Solutions for Arctic Offshore Drilling by Alain Wassink and Remco van der List, et al, Gusto MSC.