This case study involves a project between a technology developer and a large independent exploration and production (E&P) company, Devon Energy, to find solutions for downhole rod pump systems impaired with gas interference. This case study is focused on unconventional wells.

As its number of wells grows, maintaining base production has become a key priority for the E&P company. As a solution, the operator has adopted a conventional, low-risk approach to operations that delivers measurable impact while staying within budget. This strategy keeps declining wells economically viable and ensures efficient field management.

Field Background

In the Williston Basin, the company manages approximately 2,100 wells across 430,000 net acres, primarily targeting the Bakken and Three Forks formations. One of the key challenges involves controlling natural decline in production, particularly in the Bakken Formation where wells often see rates fall between 70 and 90% compared with their initial yield within just 3 years.

To address this, the operator employs a two-part strategy that relies on the steady drilling of new wells along with a focus on optimizing production from existing wells.

Production operations rely on low-cost, high-impact interventions to extend total life, improve artificial-lift systems, and recover additional hydrocarbons. This ensures stable output from newer wells while controlling lifting costs and keeping legacy assets productive despite reservoir decline.

Problem Statement

Sustaining production through artificial-lift optimization brings operational challenges tied to produced fluids and downhole conditions. High‑salinity water with dissolved gases such as CO2 and H2S accelerates corrosion, particularly due to high chloride content. These factors increase rod-pump failures.

Longer laterals and larger fracturing jobs generate more solids, causing pump wear, sticking issues, and system failures. Rising gas production from newer rod-lift wells also worsens slugging and increases solids transport, compounding mechanical stress.

These conditions highlight the need to reassess downhole production systems, identify root causes, and implement more resilient, efficient designs.

System Analysis and Methodology

The primary objective of the project was to identify and mitigate factors limiting artificial-lift efficiency in the operator’s rod-pump wells in the Williston.

Specifically, the team aimed to address recurring issues with gas interference and solids-related wear by analyzing the downhole production system holistically.

To gain a complete understanding and implement an effective solution, the operator applied a system-level approach, evaluating not just individual components, but the interaction between the reservoir, wellbore, and artificial-lift system.

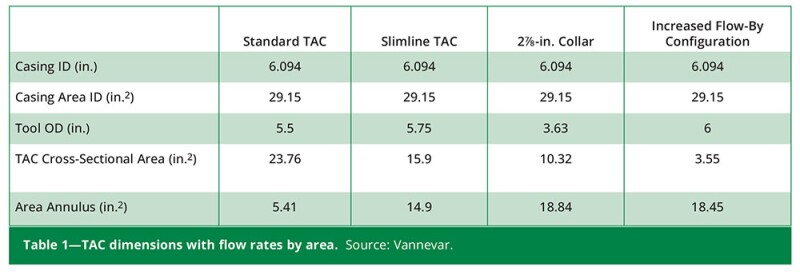

Previous industry studies have proven that gas can build up under tubing anchor catchers (TACs) causing additional backpressure on the reservoir, reducing drawdown, and limiting production (Fig. 1). Gas buildup can occur even in higher flow and smaller diameter TACs (Fig. 2 above and Table 1).

Historically, gas separators, desanders, and TACs were deployed as standalone tools. However, few vendors offered integrated solutions combining these functions.

Instead of assessing components in isolation, the team focused on the interplay between gas separation, solids handling, and annular flow dynamics. This approach clarified how these factors influence each other and affect pump efficiency and production performance.

The analysis showed gas accumulating beneath the TAC, even in reduced outside diameter (OD) or increased flow-by configurations, restricting annular gas flow and disrupting fluid intake. As a result, the operator undertook a comprehensive analysis of the downhole bottomhole assembly (BHA).

The solution was a BHA design that allows gas to flow through the TAC, which creates a larger flow area.

This process was used in niche cases since 2016 but never built into an available system that included updated gas separation and more-modern sand-separation techniques.

Conventional BHAs have a degasser section, and more-modern separators add hydrocyclones to increase gas separation.

When designed correctly, hydrocyclones generate larger gas bubbles resulting in separation of different media densities, in turn creating a smoother flow regime. The larger gas bubbles have a higher buoyancy force to aid in separation. Secondary high-velocity hydrocyclones are added at the lower end of the degasser section for solids separation.

Description of BHA Adjustments

Prior to dedicating focus on Bakken BHAs, the team predominantly ran full-size and slimline TAC units set hundreds of feet above the pump.

The team started adjusting the design with slimline anchors and quickly transitioned into building the TAC into the upper end of the degasser/desander with the inner tube running up to the upper end of the new BHA, right below the seat nipple.

The new BHA with updated components was rolled out across a portion of the field over 2 years. Its performance was backed by production data and flow modeling done during design.

Results and Business Impact

As of late 2025, the new production system has been rolled out across a few hundred wells.

Results shown in this case study compare installations between a mix of different types of TAC units set above a modern degasser desander. Not all installations demonstrated this level of increase, but the analysis is indicative of what a simple BHA swap accomplished during normal field interventions.

The sample wells each had different “modern” gas separators with some form of desanding function. A variety of TACs were used with the separators. The tubing pulls were due to normal well-failure issues, and no other large remedial work was done during the tubing pull.

Performance Analysis Across Test Wells

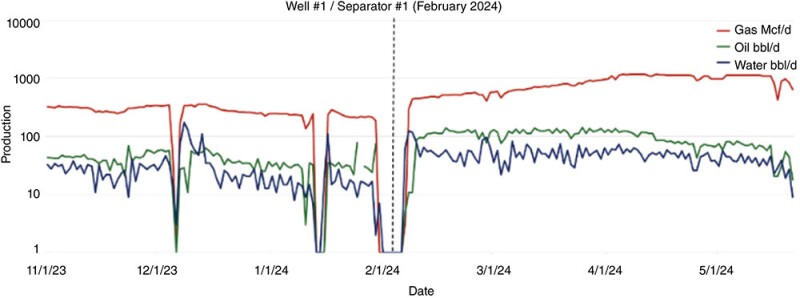

Well #1 (Fig. 3) had a hole in tubing, which required the tubing to be pulled. The BHA that was pulled was a conventional TAC set 70 ft above the improved degasser. A flow-through BHA was installed at the same depth with the seat nipple using a similar pump.

Following the February 2024 intervention, gas production increased sharply from pre-job values of between 200 to 300 Mcf/D to a steady-state average around 1,100 to 1,200 Mcf/D, representing an approximate 290 to 310% increase. Oil production rose from roughly 30 to 40 B/D to 110 to 130 B/D, showing an increase ranging from 250 to 270%. Water production also increased moderately from 15 to 25 B/D to 40 to 60 B/D, an increase of between 150 to 180%.

The post-job uplift generated additional revenue for the lease, driven primarily by improved gas/liquid separation and stabilized flow. This analysis excluded all nonproduction days and assumed no major surface or subsurface operational changes during the timeframe.

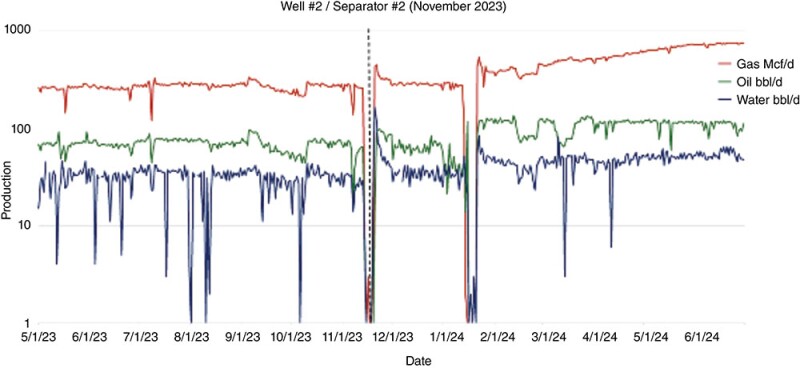

Well #2 (Fig. 4) had a hole in the tubing, requiring it to be pulled.

The BHA that was pulled was a ¼-turn full-size conventional TAC set 173 ft above the improved degasser desander. A flow-through BHA was installed at the same depth with the seat nipple using a similar pump.

Well #2 showed a significant improvement in production after the installation of a modern gas separator with a ¼-turn TAC in November 2023. In the months following installation, gas volumes increased by 37%, and oil and water by 200% to 300%, respectively.

This uplift in volume and associated revenue has been sustained for more than 18 months. The analysis excluded zero-production days and assumed no major surface or subsurface operational changes during the timeframe.

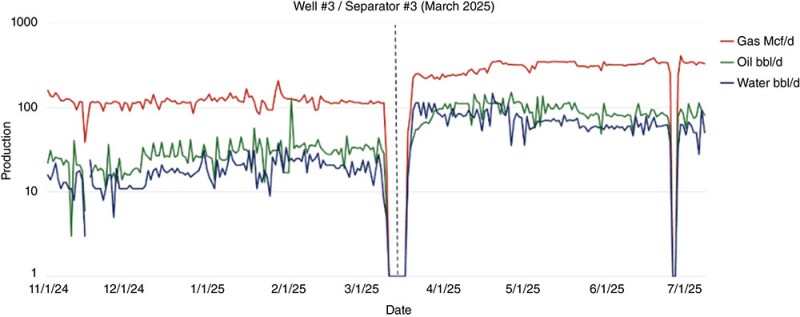

Well #3 also had a hole in tubing which required the tubing to be pulled.

The BHA that was pulled was a ¼-turn full-size conventional TAC set 324 ft above the improved degasser. A flow-through BHA was installed at the same depth with seat nipple using a similar pump.

Evaluating production trends before and after installation, the lease sustained an increase in gas rates by 120%, oil by 138%, and water by 185%. As with the other examples, the associated revenue increase contributes directly to the lease’s bottom line and overall field/asset management.

Conclusion

A system-level evaluation of the BHA focused on maximizing flow area, while still maintaining modern gas and solids separation, was key to improving production performance.

Analysis showed gas accumulation below the TAC impaired pump efficiency and fluid intake, limiting drawdown, which was difficult to previously address. By redesigning the BHA to allow gas to flow both through and around the TAC, the operator reduced gas interference and stabilized reservoir drawdown, thereby increasing production and associated revenue.

Following the pilot’s success, the operator continues to implement the optimized BHA across other Williston assets and explore adaptations for higher-pressure wells. Ongoing data collection and long-term monitoring continue to support broader deployment.

These improvements align with the operator’s goals of increasing production, lowering lifting costs, and improving uptime. The project also represents an example of effective base production optimization made possible through industry collaboration. JPT

Colter Henderson, SPE, is a senior production engineer for Devon Energy, where he leads field optimization and production operations in the Williston Basin. With nearly a decade of experience spanning drilling, artificial-lift optimization, and emissions management, he has served in multiple roles including production foreman and operations excellence engineer supporting Devon’s Decision Support centers nationwide. Henderson holds a BS in petroleum engineering from Texas Tech University and is an active member of SPE and the American Association of Drilling Engineers.

Aaron Aab, SPE, is a production engineer at Devon Energy with 17 years of experience specializing in production optimization for unconventional reservoirs in the Permian Basin and Bakken Shale. His work focuses on applying new technologies to address the distinct challenges of unconventional reservoirs compared with conventional fields. Aab holds a BS in petroleum engineering from the Colorado School of Mines.

DJ Snyder, SPE, is the founder of Vannevar, a company specializing in downhole production systems compatible with all artificial-lift methods. He holds six patents related to artificial-lift hardware and production optimization and has authored more than 30 technical papers and trade‑press articles on oilfield technology, artificial lift, and well performance. Snyder has 19 years of industry experience spanning new-product engineering, operations supervision, and company building from seed stage through sale. He holds a BS in petroleum engineering with a minor in business from Montana Tech.