Artificial lift systems arae among the most widely used production technologies in global oil and gas operations. Wells that cannot produce liquids to surface under their own pressure require lift technologies to enable production. Some liquid wells need lift assistance from the beginning, and almost all require it sooner or later. Rod pump, electric submersible pump (ESP), and gas lift technologies are the most common methods of providing artificial lift to these wells. Gas wells also require artificial lift methods in most cases to pump liquids to the surface, chiefly water but also oil, so that free gas can flow through the wellbore without impediment.

There is no global repository of artificial lift statistics; however, industry observers estimate that 90% to 95% of the world’s producing wells currently use artificial lift, said Bill Lane, vice president of artificial lift systems emerging technologies at Weatherford. “It is trending more toward 95% than 90%, and probably 100% of producing wells would use artificial lift at some point in their lives, except for wells shut in prematurely because of economic factors.”

With the ubiquity of artificial lift, “there are so many engineering opportunities in this field,” said Shauna Noonan, wells technology supervisor at ConocoPhillips and SPE technical director for production and operations.

Those who embrace those opportunities will face abundant challenges, many of them related to the integration of artificial lift into unconventional horizontal wellbore designs and frontier subsea projects in deep water.

Horizontal Well Challenges

“Today, our technologies to sweep liquids through the lateral sections of horizontal wells are very limited,” Lane said. “To understand the challenge, note that a 5,000-ft lateral with a cased 4-in. inside diameter has the same slenderness ratio as a ¼-in. drinking straw as long as a football field. Along that straw are numerous undulations, each of which results in a sump in which liquids collect. Wherever this phenomenon occurs, the pressure beyond each sump must increase until the collected liquids are blown further toward the heel of the producing zone. This phenomenon is particularly evident in gassy liquid wells, less so in primary liquid producers.”

In a perfect world for artificial lift, “the obvious solution would be toe-up straight lateral sections free from undulations,” Lane said. “But that is easier said than done.” Making wellbores straighter would help from a pumping standpoint. However, other factors usually take precedence. Bores must target the reservoir’s “sweet spots” with the most total organic content. Petrology and geophysics determine where stimulation can be most effective. Well pad designs and lease boundaries can also constrain well placement and design.

Mechanical pumps have been deployed into lateral wellbore sections with limited success, experiencing higher than normal failure rates when operating on their sides and encountering problems in keeping gas separate from liquids—a necessity for efficient pump operation. Pumps with single intakes can only pull liquids from one low spot. Thus, locating a pump along a lateral bore with multiple sumps becomes a matter of compromise. For the most part, mechanical pumps are landed in the vertical or near vertical sections of horizontal wells, and are typically not landed beyond 60° deviation.

A Critical Need in Shale Reservoirs

It is hard to overstate the importance of artificial lift in the development of shale reservoirs, in which so many production wells are being drilled. High initial production (IP) rates typically fall off rapidly, so artificial lift is required early in the lives of these wells. Continued rapid production declines may require changing to alternate lift forms in the first few years of production. Thus, project teams must consider artificial lift over the life of the well as part of their upfront planning for well location, well construction, and completion design.

“I need to get the pump intake pressure as low as possible, and for that the pump must be as close as possible to the horizontal section,” said John Patterson, global production engineering chief at ConocoPhillips. “If the well completion forces the pump to be set higher, then the well may start loading up with water and be in danger of dying. In any case, it will have a higher operating cost. So while we achieve the high IP rates, we may be sacrificing the ability to produce these wells in year 2, 3, and beyond.”

Casing diameter can be an issue as well. Excessive gas intake impairs pump performance. Production tubing can serve as a natural separator for gas and liquid, with gas sent to the tubing casing annulus—through which it flows freely to the surface—and liquids pumped through the tubing. The annular space is a key variable.

“We struggle now with the impact of completion decisions to run 5½-in. casing vs. 7-in. casing,” Patterson said. “The diameter of difference between the equipment and the casing means a tremendous change in how much gas you can handle. The bigger the casing, the more gas that can flow to the surface without taking it into the pump.”

Casing also affects equipment size. As casing diameter narrows, pumps must be lengthened to provide the same amount of horsepower. “That makes them harder to install and maintain for optimal performance and increases the risk of pump damage as they are handled in the hole,” Patterson said. “Wellbore paths also affect this. We can drill fancy wells, big stepouts, and we can turn the corner from vertical to horizontal really fast, as with many of the unconventional wells. But if you turn the corner that fast, it becomes pretty difficult for the artificial lift equipment to make the turn. This again can risk pump damage and affect performance.”

Importance of Life Cycle Analysis

“In the projects and facilities world,” Noonan said, “people use the term ‘management of change.’ If a change is recommended, the team does a full look back to see what effect it would have.” A similar life cycle analysis approach in the drilling and completions community would be helpful, she said. “People should ask, ‘If we are going to leave the operations staff with these wellbores, what impact will that have?’ ” Noonan said. Big offshore development projects such as those in Brazil often have large multidisciplinary groups that examine questions of this type. However, that is not necessarily true for much US onshore activity. “Sometimes, decisions made to save a small amount of money will result in huge costs later in equipment reliability,” Noonan said.

Another challenge is to use data more effectively to optimize production from artificial lift wells. “There is probably a greater opportunity in the near term to improve production through optimizing existing wells than through new installations, especially in unconventional wells where production conditions change rapidly,” Lane said. “However, this involves managing levels of data that are increasing exponentially. One operator has gone from 20 data sets per well per day 4 years ago to almost 200,000 data sets per well per day today.”

Efforts such as this require a sophisticated production management system that can perform well surveillance, manage the data, alert field personnel on well issues and opportunities, and provide integrated analysis for optimizing single or multiple wells.

“Systems exist that provide all of this and that integrate reservoir analysis, manage field services, and track key performance indicators,” Lane said. “The challenge is not in developing the technology but in transitioning to it. This requires a long-term commitment between the producer and the system provider, in which training and procedures development are key success factors.”

An additional factor of growing importance is the need to reduce field emissions, which affects artificial lift along with other production operations. Many wells operate on stand-alone internal combustion engines that run on produced gas. Converting to centralized electrical generation can improve an operation’s carbon footprint by reducing emission points to a single location at which to install improved control technologies, Lane said. More efficient power sources such as fuel cells may also play a future role, as their use in industry expands and costs decline, he said.

Innovations Expand the Technology

As operators seek additional ways to meet specific field production needs, a number of innovations are expanding the artificial lift technology envelope.

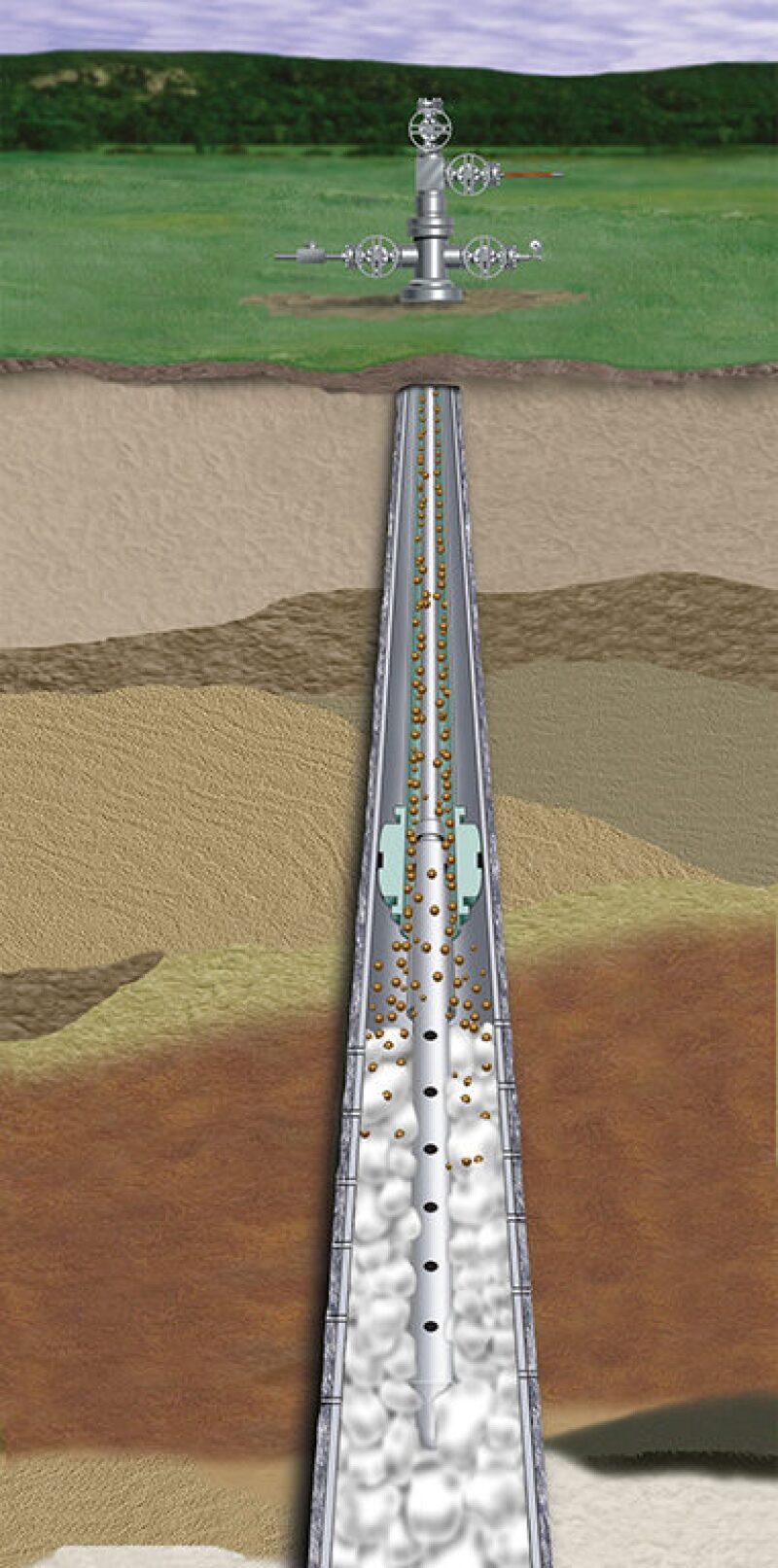

In gassy wells, one promising technique for removing produced liquids is velocity enhancement. Inserting tubing called a velocity string or dead string into a horizontal wellbore can increase gas velocity by reducing the flow cross-sectional area to help the gas flow sweep liquids to the heel.

Gas injection from the surface into the horizontal section can also increase gas velocity temporarily, as long as the injection pressure exceeds the flowing bottomhole pressure. However, the inflowing production fluids will become restricted as the injection pressure approaches the static bottomhole pressure (SBHP). Eventually the SBHP will decline to the point at which velocity enhancement by velocity strings and gas injection is no longer effective.

Foam lift in horizontal sections holds some promise. Surfactants can be used to turn liquids into foam so that gas flow in the well can more easily push liquids through the lateral section and to the surface. Foam lift has yet to see wide use because of difficulties in deploying capillary tubing and achieving optimum surfactant concentrations in laterals that have multiple production inflow points. Weatherford has been successful in using foam to dewater 4,000-ft-long laterals in the Barnett shale, so the technology could begin to have a broader application in shale plays, Lane said. There also is potential to combine foam lift with velocity enhancement, he said.

In new pump technology, the geared centrifugal pump (GCP) is similar to an ESP, but is rod driven from the surface by hydraulic, electric, or internal combustion power. The GCP removes the operating risk of a downhole electric motor and power cable while pumping at rates comparable to an ESP and in some cases with greater efficiency, particularly in narrower casing. In liquid production, the GCP is more tolerant of gas inflow than an ESP.

“We are also doing things like through-tubing installations of ESPs in areas where rig and downtime costs are high if you have a heavy failure,” Patterson said.

However, the latest pump-related innovations are largely niche applications, and not all of them are new technology, Patterson said. “Some of these things were tried 30 years ago, but what has made them new is improved materials—new elastomers, new steels that allow us to take things to higher loads. Those types of things have taken equipment that would not work for very long and made it fairly reliable.”

More Knowledge of Current Technology Needed

While new technology is welcome, it may not be the most pressing need. “We don’t need new widgets for the most part, even though some in the industry may be calling for that,” Noonan said. The biggest advancement may lie in improving the industry’s knowledge of currently available technology: its capabilities and the proper selection, installation, and operation of the equipment.

“A lot of the equipment is the type of thing that has been around for ages—ESPs, gas lift—and we still need to understand how it operates,” Patterson said. “We need to understand the boundaries of how we can use it with these new well geometries. We don’t really know that.

“How much can I push a piece of equipment through certain doglegs? We have some calculation methods; unfortunately, they are extremely conservative. They tell us, ‘You can’t do that,’ but we’ve already done it. How do we handle gas separation in these wells? How do we handle slugging wells by type of lift—rod pump, jet pump, gas lift, and ESP? How can we push this equipment to maximize our production and handle some of these wellbore environments?”

Changes in reservoir conditions also have an important influence. “When you start an ESP or rod pump at high fluid levels, it operates differently than when you get down to very low levels of fluid, very low intake pressures—and we need to understand that,” Patterson said.

Understanding Failures

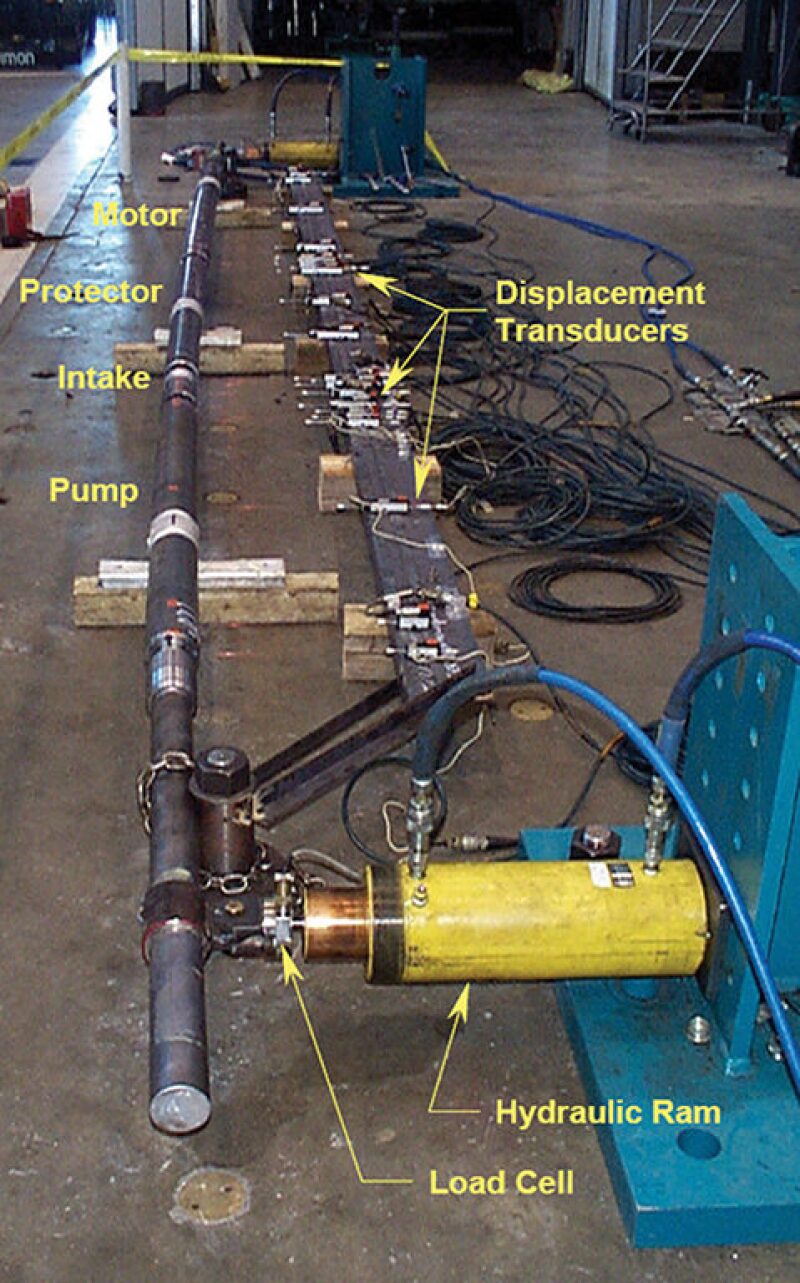

C-FER Technologies, a nonprofit engineering, testing, and applied research organization in Edmonton, Alberta, Canada, maintains an extensive failure database for ESPs and progressing cavity pumps (PCPs) as part of two joint industry projects. (PCPs are rod pumps commonly used in artificial lift.)

Francisco Alhanati, managing director of C-FER, said, “Certain conditions can be harsher on the equipment, like high temperatures. In very few instances, however, is there evidence of the equipment wearing out. In most cases, the circumstances leading to the failure are associated with issues involving the equipment design/selection or use, including installation and operation. There are also cases associated with equipment manufacturing, including quality control, but these are not the majority.”

Equipment standards have not been as broad in artificial lift as in some other industry sectors. “Until recently, the only standards that existed were for beam pumps and gas lift,” Noonan said. “For other types of artificial lift, there were just recommended practices until the past few years. Now some of those standards are being developed and published.” The establishment of these standards should have a positive effect on manufacturers and operators.

Experience within the artificial lift discipline is another important issue for the future. Many within the industry, including veterans such as Noonan and Patterson, consider the sector’s experience level low. As with the rest of the industry, a sizable portion of the experienced workforce is close to retirement. Thus, knowledge transfer is critical. At the same time, the artificial lift community is probably busier than ever. With so many wells being drilled and the steep early decline rates of unconventional wells, the need for artificial lift will remain high and likely increase. Those who develop the necessary experience will be in great demand. Said Noonan, “Graduating engineers choosing artificial lift as a specialty could make it a really rewarding career.”