Maximizing the efficiency and safety of subsea robotics demands more than just advanced underwater vehicles: it requires a support infrastructure.

Universal charging will enable consistent power for future subsea-residency applications, while passive asset identification could improve accuracy in low- or no-visibility conditions. And as the domain of underwater robots expands, a proposed standardization of descriptions will help clarify the capabilities of the subsea fleet.

Keeping subsea resident drones ready to operate requires keeping them powered up through subsea charging.

One vision is for fully interoperable subsea charging locations so any underwater vehicle can land on the docking station to power up through wireless inductive charging technology.

While presenting OTC 35570 at the Offshore Technology Conference (OTC) in Houston in May, Unplugged Chief Operating Officer Thomas J.J. Meyer compared such subsea docking stations (SDS) to land‑based gas stations.

“These charging stations are not so different from the ones you may find topside, not so different in the sense that any drone—any drone from any vendor—can land, dock, charge, and also communicate with the rest of the infrastructure,” he said.

Interoperable SDSs allow underwater intervention drones (UIDs) to remain stationed on the seabed, reducing the reliance on surface vessels and human intervention for launch or recovery of the unit for each mission. This approach reduces costs, improves safety, and reduces emissions. It also eliminates the need to wait out unfavorable sea-state conditions for robot deployment because the subsea vehicle is already stationed on the seabed.

The authors suggest that where repeated missions are planned, or in situations where owned UIDs might be transferred across fields, placing an SDS on the seabed for a capital expenditure of $1 million to $2 million presents a compelling business case over repeated deployments of a remotely operated vehicle (ROV) or autonomous underwater vehicle (AUV) from a vessel.

But deploying an interoperable SDS comes with challenges. Subsea units often feature proprietary docking and charging systems, making standardization difficult. Additionally, efficiently transferring power and data underwater remains a technical hurdle.

These challenges are ones that operators like Equinor would like to see overcome. Equinor, with its numerous projects on the Norwegian Continental Shelf (NCS), has supported subsea residency efforts in the area. During two deployments, Saipem’s Hydrone-R was resident on Equinor’s Njord field for more than 8 months, completing a cumulative total of 240 days of continuous operations and more than 280 docking missions from an SDS. Currently, there are two other SDSs in place offshore Norway, with two additional installations planned and about a dozen more under consideration.

In 2019, three SDSs were built and tested with different underwater vehicles. The Saab Seaeye Sabertooth AUV was used at the Saab test center in Sweden, while Saipem’s Hydrone-R UID was tested in Saipem’s test center in Italy. Oceaneering’s Freedom, Stinger Technology’s eponymous Stinger UID, and the M-series snake-shaped drone from Eelume were all tested at the Tau Autonomy Center near Stavanger, Norway.

“How can we be so successful in putting charging stations on the bottom of the sea? Well, the secret sauce is: there is no secret sauce. You can come to me after the meeting and ask for the CAD (computer-aided design) drawings of the charging station, and I will give them to you. It’s all open standard,” Meyer said. “The charging station itself follows the API 17F standard, meaning that the structure itself can last 25 years at the bottom of the sea.”

The base must be resilient enough to accommodate repeated landing impacts and remain operable, he said.

He said the station’s communication protocol and electrical interfaces meet the Subsea Wireless Group (SWiG) Standard and that prominent drone manufacturers have incorporated couplers compliant with the standard, ensuring compatibility.

“It means that if your drone manufacturer follows the SWiG Standard, your drone will dock and charge on the same charging station, exactly what you would expect with your car. This explains why Saipem drones, the Saab drones, and the Oceaneering drones, they all dock and charge on the same charging station,” he said.

An early decision in power transfer was choosing between wet-mate connectors and wireless technology. A wet-mate connector is similar to on-land charging but has limitations, such as the need for precise alignment and the amount of force required for the mating and de-mating operations. Its operational functionality tops out between 500 and 1,000 mating cycles, so daily use would limit its lifespan. Finally, the pins in a wet-mate connection are susceptible to corrosion.

Wireless charging technologies considered included capacitive, inductive, radio frequency, and optical methods, with inductive deemed the most viable option. While modern on-land wireless inductive systems deliver high power capacities and efficiency, subsea capabilities lag. The subsea power-transfer capacity of 2.5 kW has been chosen for recharging UIDs. A modern work-class UID’s battery pack ranges from 20 to 80 kWh and requires from 8 to 32 hours to charge fully. Because there is typically sufficient downtime between missions, the charging time is of limited concern, the authors wrote.

The current SDS wireless technology is qualified for a 15-year design life, operates in 3000‑m water depth, and transmits data at a rate of 100 Mbps.

Looking ahead, the authors noted that the SDS offers a clear path toward establishing a universal standard for subsea drone operations—similar to the interoperability seen with on-land refueling stations. However, industry collaboration will be required to further refine SWiG standards and promote their global adoption. They also see the continued evolution of subsea technology as helpful in addressing current limitations like raising inductive power-transfer rates from 2.5 kW to 5 or 10 kW, and scaling data transfer rates from 100 Mbps to 1 Gbps or higher to support more data-intensive missions.

Beyond Toll Booths

Passive ID Tags Could Reduce Subsea Errors

Technology used in daily life to recognize individual items, like a car passing through a toll booth, might one day be used to identify subsea infrastructure.

The idea of using a passive identification technique subsea is appealing because it can minimize the amount of time an underwater vehicle spends looking for a specific asset as well as minimize the chance that maintenance is carried out on the wrong equipment, Marcelo Brack, technical consultant at Petrobras, said while presenting OTC 35706.

Petrobras and Brazilian startup I-DUTTO partnered through the Connections for Innovation Program to assess the feasibility of using radio frequency identification (RFID) technology in offshore environments. According to the paper, results from the year-long research project indicate the possibility to overcome one of the chief barriers of using RFID underwater: the high attenuation of radio electromagnetic waves in a subsea environments, which limits the communication range between devices.

Historically, subsea assets have been identified visually, using cameras to recognize alphanumeric codes, bar codes, or QR codes painted or attached to surfaces. However, these markers can be damaged by subsea conditions or during handling and installation—and they can be difficult to spot in low- or no-visibility conditions.

Brack said the goal is to one day be able to integrate an RFID reader device into an autonomous underwater vehicle (AUV) that could energize and pick up radio signals from a passive battery-free tag on subsea infrastructure. Such a setup could help lower costs, minimize identification errors during underwater operations—even in low- or no-visibility conditions—and enhance automated navigation and positioning capabilities.

But RFID must overcome several challenges beyond signal transmission range to be effective in saltwater environments. Challenges include antenna design and ensuring the durability of passive tags, which may face marine growth, fouling, burial in seabed sediment, or detachment from the infrastructure.

To determine the feasibility of using RFID technology subsea, Petrobras and I-Dutto began by testing commercially available readers and tags in 13 different configurations in a small tarpaulin pool. The goal was to see whether the system could achieve a minimum communication range of 40 cm—a safe distance to prevent the vehicle from colliding with tagged infrastructure.

“These configurations depend on the frequency—the adopted frequency—the power, some geometric parameters, and the dimensions of the tag,” Brack said. “We varied all these parameters to establish the configurations.”

In the initial testing, three of the configurations achieved communications ranges between 30 and 40 cm, while a fourth exceeded 40 cm. The next round of testing for the fourth configuration occurred in a larger, saltwater-filled pool.

While the minimum targeted communication range for the project was 40 cm, round two testing revealed the possibility of achieving communications at almost 60 cm.

“We have reached here almost 60 centimeters. It was, for us, a bit of a surprise, because in the beginning of the project we expected smaller values,” he said.

Surpassing the 40-cm goal by 40% was significant, he said, because of concerns that an underwater vehicle may not approach the tag from a head-on orientation. The second round of testing showed that even when a device reader on an underwater vehicle approached at an angle of up to 60°, it still maintained a communication range of more than 40 cm between reader and tag, he said.

“The results indicate the feasibility of applying this technology,” he said, noting the goal is not to replace visual-based identification with the RFID‑based method, but rather to complement it.

Brack said the expectation is to move toward prototype and field testing with RFID devices requiring additional development. As the companies work to further develop the technology’s capabilities, he said, the idea is to achieve a minimum communication range of at least 1 m, focusing on operations with AUVs.

“It depends basically on developing new devices and also perhaps having higher power levels,” he said.

Other work could focus on encapsulating the tag electronics, developing tools for attaching tags to subsea infrastructure, designing hardware to integrate reader devices on underwater vehicles, and other related advancements.

“Our expectation is to reduce costs and risks with deficiencies of exclusively visual methods” of identifying subsea assets, Brack said.

Navigating the Nuances

Making Sense of the Subsea Robotics Landscape

Once, it was clear what an underwater vehicle’s basic capabilities were. With the proliferation of new robotic offerings, it can be difficult to compare functionalities using traditional differentiators like control method or task.

The newer generation of subsea vehicles, designed to overcome specific limitations of remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs), may be referred to as underwater inspection or intervention drones (UIDs).

A standardized classification system would make it possible to avoid confusion, particularly as hybridization blurs the line of traditional functionalities, Giovanni Massari, head of Sonsub, which is Saipem’s subsea robotics development and operational center, said while presenting OTC 35846.

“Subsea robotics is changing quickly. So, we are moving from a conventional ROV and AUV market that is well known to something different, where there are multiple different solutions,” he said.

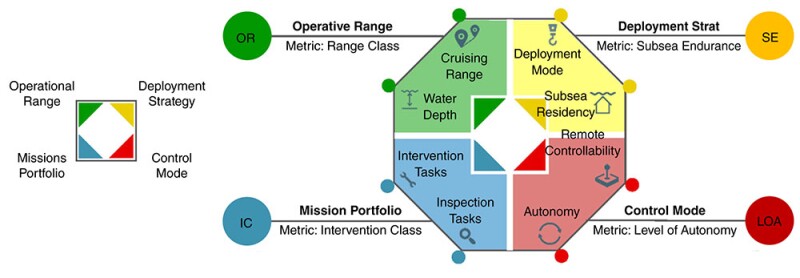

Massari and his coauthors propose a common language focused on a quartet of parameters: mission portfolio, operating range, deployment strategy, and control mode.

To describe the mission portfolio, the authors propose five intervention class (IC) designations related to noncontact or contact inspection, level of tooling, and manipulation capabilities, ranging from IC 1 indicating contactless measurements and unintrusive inspections to IC 5, indicating heavy-work-class capabilities, complete with heavy tooling and manipulation ability.

Regarding control modes, the authors propose six levels of autonomy (LoA) related to the extent of human involvement, the portion of the task performed autonomously, and the level of communication required. An LoA 1 would indicate fully manual operation. The degree of autonomy increases through the levels to assisted (LoA 2), delegated (LoA 3), supervised (LoA 4), collaborative (LoA 5), and fully autonomous (LoA 6).

The operating range class (RC) categorizes vehicles based on a combination of water depth—from shallow to deep—and cruising range from short to long distances. An RC 1 vehicle would operate in shallow water within 1 km of its point of deployment, while an RC 4 vehicle would operate in deep water more than 20 km from its launch site.

The subsea endurance level (SE) defines the deployment strategy, ranging from a single-mission dive (SE 1) to operations involving multiple missions while remaining subsea for more than 6 months (SE 4).

Massari said Saipem was proposing the classification system based on lengthy discussion with different players “as a way to define and to compare different underwater robotic solutions.” The proffered taxonomy, he added, “should be considered like a starting point” that could lead to further refinement through a collaborative effort aimed at codifying a common language.

For Further Reading

OTC 35570 Enabling Resident AUV and ROV Subsea Operations: The Role of Wireless Inductive Charging and Docking Stations by T. Meyer, H. Mubasier, and K. Humborstad, Unplugged; H. Eide, Subsea USB; A. Vasilijevic, Norges Teknisk Naturvitenskapelige Universitet; J. Torvestad, Equinor.

OTC 35706 Underwater RFID Applications for Agile, Accurate, and Safe Identification of Subsea Pipelines and Equipment by M. Brack, C. Lima, R. Ribeiro, and M. de Souza, Petrobras, and V. Carneiro and G. Colvero, I-DUTTO.

OTC 35846 The Final Method to Sort Out Underwater Drones Classification Problem by G. Massari, F. Cavallini, and G. Zornetta, Saipem Spa; C. Marras, Saipem Ltd; and J. Torvestad, Equinor ASA.

Click here to read related story about subsea resident drone technology.