Improving oil production from mature fields is a significant challenge because of rising recovery costs and fluctuating crude oil prices. Although large investments are made in finding new reserves, typically more than 60% of discovered oil is left behind. Thus, the use of enhanced oil recovery (EOR) technologies is necessary to bring more of this oil into production. This article describes how the use of a biological EOR technique that applied produced water for reservoir flooding in a mature field led to rapid and substantial increases in oil production.

Glori Energy’s Activated Environment for Recovery of Oil (AERO) technology is a biological EOR method in which customized nutrients are injected into the reservoir to activate native microbes. The ensuing microbial activity improves oil mobility and leads to increased production in waterflooded sandstone reservoirs.

Use of the technology involves minimal capital spending and low operating costs, and applications can use existing field infrastructure. Reservoirs respond quickly to the use of the method, showing higher oil rates and increased oil cuts. Recovery is increased, and the economic life of the field is extended.

Oil fields are screened in a two-step process that includes reservoir analysis and treatment design. Reservoir analysis involves geological assessment to determine key characteristics such as porosity, permeability, structural alignment, net pay, oil gravity, injector/producer continuity, and historical production response. The analysis allows for a quick review of multiple fields to select the one predicted to benefit most from biological EOR.

Treatment design comprises biochemical testing and nutrient formulation. The process starts with the sampling of reservoir fluids under controlled conditions, using specialized equipment from pertinent locations such as injection, production, and source-water wells. Chemical analysis is begun immediately upon the sample’s arrival to determine the physicochemical characteristics of oil and water. Biological testing comprises assessing the viability of native microbial populations, developing a customized nutrient blend tailored to the field, and confirming the suitability of injection water for supporting microbial activity.

The achievement of residual oil recovery results from the stimulation of specific indigenous microbial communities exclusively in the near-injector region. A low concentration of low-cost, inorganic nutrient is added continuously to the injection water to stimulate growth of the resident microbial populations on residual oil. The growth disrupts the interfacial tension between oil and water, improves oil mobility, and enhances the sweep of the flood by diverting water into previously unswept channels that contain residual oil.

Because the goal is to stimulate growth in the formation at the oil/water interface, the injection water must be largely free of bioavailable carbonaceous compounds (e.g., oil, organic acids) or the nutrients will be consumed independent of their growth on residual oil. Thus, produced water for reinjection (PWRI) can require conditioning to reduce the concentrations of free oil and total organic carbon.

Case Study

Biological EOR was implemented in a small pilot area of a large, mature waterflooded Southern California field (SCF) through continuous nutrient injection into the PWRI. The project planning began with reservoir analysis and fluid sampling to assess biogeochemical compatibility.

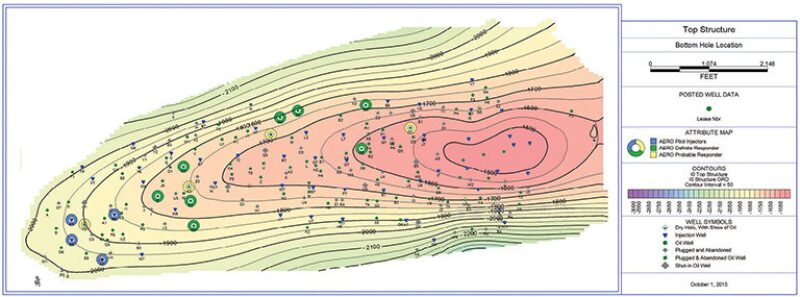

Geological assessment characterized the SCF as an east-west trending anticline, plunging toward the southwest and truncated on the northeast by a regional fault. The field was found to produce from a stratigraphically complex formation at depths of 2,000 ft to 4,100 ft. Strata were coarse clastic turbidites deposited in a deepwater environment on submarine fans. The rock types included sand, shale, silt, and conglomerate with interbedded sand-silt and shale.

The formation was divided into four zones and 16 individual reservoir units, with four original oil/water contacts. The net reservoir thickness varied from 25 ft to 120 ft, the porosity averaged 20% to 26%, the oil gravity ranged between 20 °API to 36 °API, and the permeability was between 200 md and 1,300 md, with continuity between injectors and updip producers. All features were considered favorable for implementing biological EOR.

Biochemical testing showed that while most water quality parameters were favorable, free oil content and aqueous organic carbon were above the permitted levels. This indicated the need for a free oil removal process. Biological experiments revealed that the aqueous organic carbon was not bioavailable and would not compete for nutrients with the biological EOR process. Additional biological experiments were used to validate a nutrient solution that stimulated growth of the indigenous microbial communities on oil and this was developed for field application.

As a consequence of the biological studies, a surface system for water conditioning and nutrient injection was designed to remove oil from the PWRI and deliver customized nutrients to each of the four target injection wells. The oil removal system consisted of 19 depth-style polyester filter elements situated within a horizontal housing that coalesced the free oil from the PWRI.

The horizontal configuration of the housing created additional rising time for the coalesced oil, which was directed to a storage tank. A volume surge tank, from which the oil had been removed, served as the injection water storage tank for the triplex injection pump. The nutrient injection skid consisted of a high-pressure, low-volume dosing pump in addition to an air compressor and receiver.

Nutrients were injected into the water suction line of the triplex pump and pumped into a four-way manifold for continually delivering water and nutrients to each injector. In addition, precisely controlled air from the nutrient injection skid was delivered by means of mass flow controllers to each wellhead. Operational stability was maintained through regular field quality control assessments and satellite monitoring of the nutrient injection system.

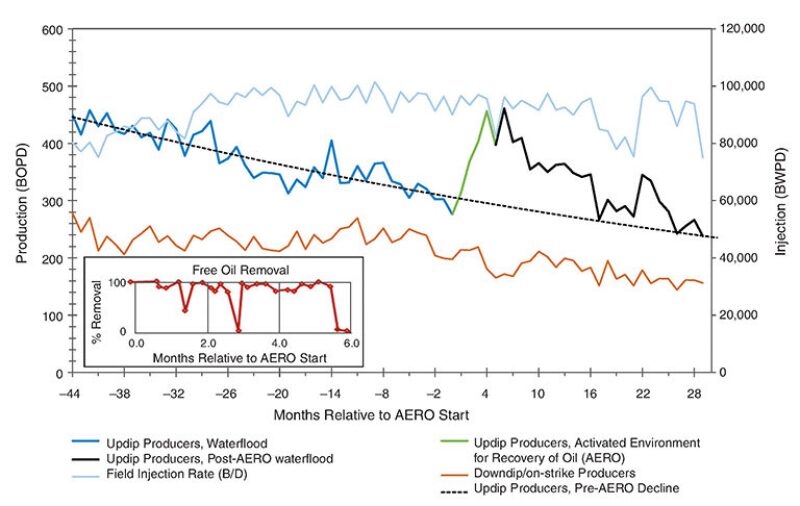

Oil production was assessed in wells considered by the operator to be in the monitoring area, representing an output of about 500 B/D. Enhanced production was first noted 3½ months into the project and peaked between 5 and 5½ months (Fig. 1). A decline in the final month coincided with a downturn in field injection and production volumes.

Assessing the response exclusively from full-field production data, the increase was almost 130 B/D in wells updip of the injection wells. However, monthly changes in injection volume complicate the short-term analyses. Individual production well data were statistically noisy, but when average production over the 4-month window (including the 2 weeks following the pilot project) were compared with the 7-month, pre-project period, eight wells had demonstrable increases.

The eight responding wells showed a 1.2- to 2.5-fold increase in oil cut and a 1.4- to 3.5-fold increase in oil rate, which equated to a 66 B/D increase in oil production.

Another four wells with similar production patterns had a 25 B/D production increase over the same period. However, because of statistical noise and the short project duration, we consider these to have been probable rather than certain responders to the pilot treatment.

Thus, even with monthly data resolution and a short, 6-month pilot, we were able to identify a 1.6- to 2.0-fold increase in oil rate and a 1.5- to 1.7-fold increase in oil cut, resulting in a 66 B/D to 91 B/D increase in production from select production wells.

While these production increases are less than the 130 B/D increase observed in monitored field production during the pilot project, the difference of 40 B/D to 70 B/D could have resulted from month-to-month variations and/or the sum of enhancements too small to resolve in a 6-month period. Viewed against the decline shown in Fig. 1, these changes are even more favorable, with the pilot project showing a marked deviation upward that remained above this baseline for almost a year.

In addition to the overall production increase, the response pattern was notable. In previously published results from projects performed with this technology on waterfloods in Kansas (Bauer et al. 2011) and Alberta (Havemann et al. 2015), responding wells were structurally updip and distant from the injectors. This project was similar, in that the responding wells were updip of one or more treated injectors, and some were more than 2,000 ft away (Fig. 2). This is consistent with the response patterns observed in core experiments (Jones 1985; Sunde et al. 2012) where oil travels much faster than the injected water, resulting in a rapid response from a drop in pressure.

Based on the positive results obtained from the current and several other field applications, biological EOR is an effective and economic approach for recovering trapped oil in mature, waterflooded fields that are approaching their economic limit. Furthermore, the application of PWRI to the method has now been validated through the use of established water conditioning technology on only a fraction of the total injection water.

References

Bauer, B.G., O’Dell, R.J., and Marinello, S.A. et al. 2011. Field Experience from a Biotechnology Approach to Waterflood Improvement. Presented at the SPE Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 19–21 July. SPE-144205-MS.

Havemann, G.D., Clement, B.G., and Kozicki, K.M. et al. 2015. New Microbial Method Shows Promise in EOR. J Pet Technol 67(3): 32–35.

Jones, S.C. 1985. Some Surprises in the Transport of Miscible Fluids in the Presence of a Second Immiscible Phase. SPE J 25(01): 101–112.

Sunde, E., Asa, S., and Lillebø, B. et al. 2012. Towards a New Theory for Improved Oil Recovery from Sandstone Reservoirs. Presented at the SPE Improved Oil Recovery Symposium, Tulsa, Oklahoma, 14–18 April. SPE-154138-MS.