Oilwell leakage poses significant environmental, economic, and operational challenges to the oil and gas industry. Remedial operations in oil and gas wells are quite challenging, especially for narrow apertures, and often require treatment materials tailored to specific challenges encountered in downhole environments. Geopolymers represent a low-carbon and environmentally friendly alternative to conventional cement, which can be explored for remedial operations.

This paper presents the development, characterization, and comparative analysis of Geoseal, a metakaolin-based geopolymer, as a candidate treatment material for remedial operations. In this study, laboratory experiments were conducted to evaluate the rheological, mechanical, and sealing performance of Geoseal at the sealant/casing interface.

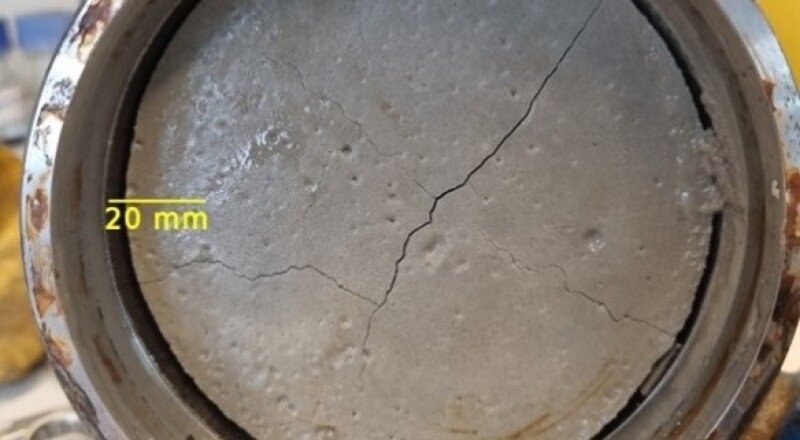

Microannuli sealing performance was evaluated by injecting the treatment fluids under simulated downhole conditions into naturally formed microannuli at the sealant/casing interface. Three sealant materials—neat G cement (S1), granite-based geopolymer (S2) (Fig. 1), and expansive cement (S3)—were considered.

The effectiveness of Geoseal in sealing narrow microannuli apertures was also compared with that of conventional remedial materials such as thermosetting resin and silicate solution. The comparative assessments focused on injectivity, sealing integrity, and material compatibility with the existing set sealants at the microannuli interface.

While each treatment fluid exhibited unique advantages and limitations, the results highlight the potential of Geoseal for effective microannuli remediation. However, its adoption in apertures narrower than 6 µm presented notable injectivity issues.

The findings of this paper provide practical insights for industry practitioners and researchers seeking to enhance the effectiveness of remedial interventions of cementitious sealants in oil and gas wells.

This abstract is taken from paper SPE 228407 by Adijat Ayobami Ogienagbon and Mahmoud Khalifeh, University of Stavanger. The paper has been peer reviewed and is available as Open Access in SPE Journal on OnePetro.