Installing qualified cross-sectional cement barriers is a difficult task. One needs to ensure that cement is displaced evenly along the required length and fills the annulus completely, which may prove difficult in some scenarios such as unknown annular content and wells with eccentric casings.

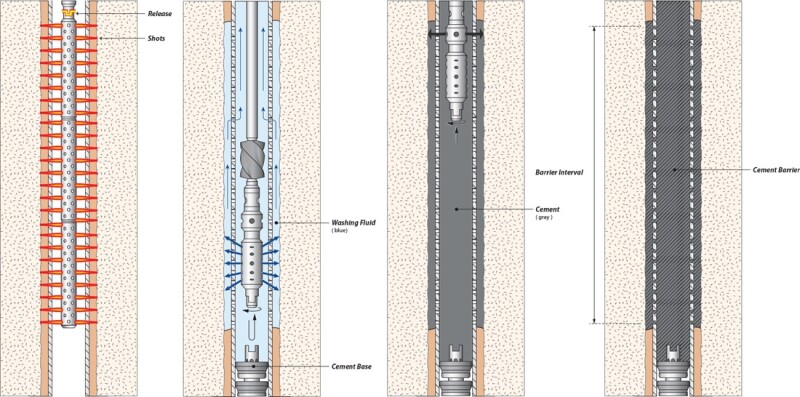

Traditional methods, such as section milling and cement squeeze, have been ineffective in delivering good results in terms of time, cost, and quality, and, as such, new techniques have been developed. In this review article, we discuss perforate, wash, and cement (PWC), a method of installing a cross-sectional cement barrier that is being deployed widely around the world for remediating poor cement and performing plugging and abandonment (P&A) jobs.

Abandoning wells will be an enormous undertaking in the short term, thus installing safe and cost-effective barriers is of utmost importance. In this context, we review PWC in terms of reported field deployments, modeling techniques with computational fluid dynamics, qualification processes according to existing standards, the establishment of track records, and the efforts to go rigless.

We conclude that establishing track records through qualification matrices is fundamental for reducing costs without incurring reduced safety as well as that performing rigless P&A through PWC could save significant costs and time in the context of thousands of wells to be plugged in the near future.

This abstract is taken from paper SPE 226204 by M. A. Jaculli, M. Iuell, E. Engelsgjerd, E. A. Knudsen, S. Amdal, P. Andersen, S. I. Haukelid, and S. Vemmestad. The paper has been peer reviewed and is available as Open Access in SPE Journal on OnePetro.