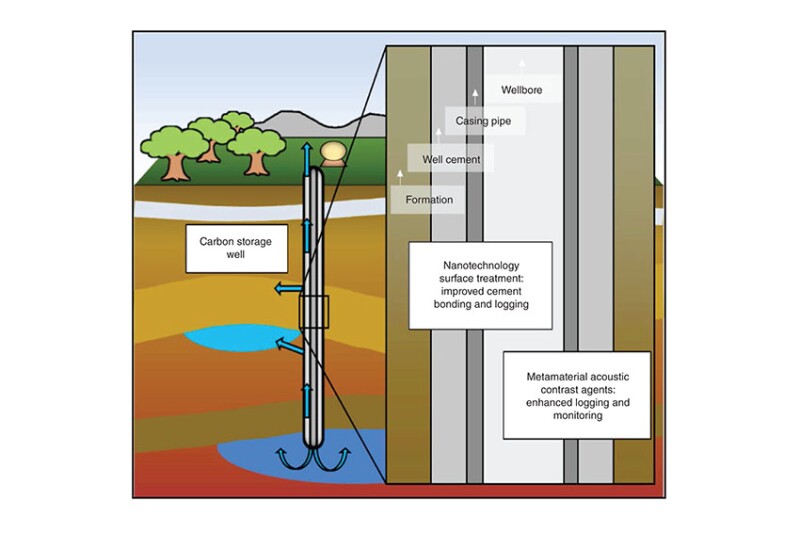

The success of CO2 injection operations, and the endurance of long-term storage, are partially dependent on well design and the materials used for well construction. The authors describe a stack of technologies they have developed that enable enhanced well robustness, monitoring of carbon-storage facilities, and modeling of their performance. The combination of these technologies enables the tracking of downhole and subsurface fluid distribution and flow. Furthermore, the scalable technologies can be used to exploit remaining reservoirs while preventing CO2-plume migration.

Introduction

Besides site selection and geological features that influence plume migration, well-construction design and materials have a major effect on successful storage.

×

Continue Reading with SPE Membership

SPE Members: Please sign in at the top of the page for access to this member-exclusive content. If you are not a member and you find JPT content valuable, we encourage you to become a part of the SPE member community to gain full access.