Fiber optic pressure and temperature (P/T) sensing technology for multizone fracturing and production monitoring is enabled by a new feed-through (FT) technology that integrates the optical fiber within the multiple elastomer elements of a compact, swellable openhole packer system to achieve competent zonal isolation.

It is important that a continuous length of optical fiber be installed across the multiple zones isolated by the swellable packer system. Splicing the fiber is problematic because the process is time c4onsuming, and the splice point degrades faster than uncut fiber. Over time, the splice presents a weak point that can limit system life. This is compounded in long, multizone completions that may require as many as 40 isolation points along the well.

Weatherford’s Fraxsis FT technology facilitates deployment of continuous lengths of optical fiber across multiple zones as part of a modular packer system made up of short (24-in.) swellable elastomer sections that provide high-pressure zonal isolation. The FT technology is also a key enabler in the development of a faster, spoolable fiber deployment capability.

Fiber optic monitoring of a fracture stimulation and the resulting production across every stage of the completion provides engineers with the information to improve stimulation and completion design, and optimize production over the life of the well. The FT technology enables fiber-optic monitoring using a proven packer technology that achieves high-pressure zonal isolation with a much shorter inflatable element, which reduces packer stiffness and makes the system easier to run.

Technical Details

The FT packer design is based on a modular approach that uses single or multiple swellable elastomer elements to create isolation points for the completion (Fig. 1 above). Each element incorporates a proprietary metal backup system to achieve a higher pressure rating with less than half the length of a conventional swellable packer.

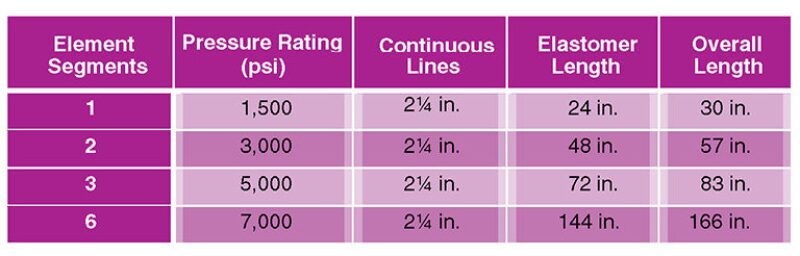

The metal backup system expands concurrently with the elastomer to prevent extrusion of the rubber element and form a higher pressure seal. Depending on the completion’s pressure requirements, 24-in. elastomer sections are added to the packer system to achieve 1,500 psi (one element), 3,000 psi (two), and higher-pressure specifications. As a result, the technology allows a packer only 7 ft long to seal up to 5,000 psi with the same hole-conformance of traditional swellable packers.

The base module is a 24-in. packer element with exposed back-up rings. Specifications for the initial 6.25-in. hole-size packer include a 4.5-in.-OD mandrel, 5.65-in.-OD element, and 5.75‑in.-OD gauge. A 5.5-in. open hole size is planned.

The new FT technology feeds two ¼-in. fiber lines through the packer elements: one for temperature sensing throughout the well, and one with integrated pressure gauges to provide pressure measurements along the wellbore.

Feed-through deployment of the optical fibers is achieved by incising two precise ¼-in.-wide slots approximately ½-in. deep and opposed 180° along the length of the element. The fibers are inserted in these grooves.

The cutting process produces an extruded strip of rubber that is approximately the same size as the slot. After the FT slot is incised, the extrusion is retained and replaced in the groove prior to wellsite delivery of the packer. The incision has a rounded profile to help hold the replaced extrusion in place.

Running Process

In the running process, the tool is made up with the string in the same manner as conventional swellable packers. The pre-cut rubber extrusions are removed from the FT slots in the element and the two fiber cables are inserted. The extrusions are replaced and pressed into the slot using a rubber extrusion insertion tool (REIT).

The REIT hand tool sets the rubber extrusion in place so that it covers the fiber cables and integrates them within the element. Sets of C-rings that are integral to the metal back-up technology are installed at either end of the element to further secure the fiber FT. Grooves in the C-rings ensure that the clamps provide the optimal pressure against the fibers as they exit the element. Full integration and sealing of the fibers within the elastomer is further enhanced when the elastomer swells and pushes against the formation.

Installation time is always a concern with the deployment of downhole monitoring systems. The FT installation requires less than 15 minutes per packer.

Testing

Successful testing of the FT packer system was completed in October 2013. The testing process applied the same standards used for conventional openhole packer designs. An oil-actuated, H4WON elastomer with a maximum 300° bottomhole temperature was used in the initial tests. Pressure was applied alternately to each end of the assembly according to modified V3 ISO 14310 cased-hole standards to achieve a less-than-1% pressure loss over a 15-minute period.

The modular system was tested in one-, two-, and three-element configurations. Tests proved that a maximum 7,000 psi can be achieved with a six-element assembly that has a combined elastomer length of 144 in. and an overall assembly length of 166 in. (Fig. 2).

Test results showed that the FT process of incising and replacing the rubber extrusion avoided any communication along the fiber FT channel. There was no leak path and the FT incision healed competently when the extrusion was replaced and swelling took place. The trials occurred during a standard 3-week period for swell-testing procedures.

Field Deployment

The success of the tests proved the tool was ready for field application and it is currently pending initial commercial deployment. Plans include manufacture of a 5.5-in. openhole tool, and completion of the development of a spoolable fiber system enabled by the FT capability.

Editor’s note: If you have a new technology introduced fewer than 2 years ago and would like to highlight it in Young Technology Showcase, please contact JPT Editor John Donnelly via email.