An oilfield services company that has built a business sealing tiny leaks in cement is now trying to show it can use its technology to build and repair roads and runways in war zones.

BioSqueeze was recently awarded a contract by the US Air Force to test whether its technology, which uses a mix of chemicals and bacteria to create rock on demand, can be used to repair and build runways in difficult situations, according to a company release.

It is also in the second year of a similar contract with DARPA, an agency that manages research and development projects for the US Department of Defense (DoD). That project is seeking a method to stabilize the sand for beach landings to facilitate heavy equipment traffic.

In both trials the company must show it can create a strong surface using various types of water, soil, sand, or dirt, said Hayden Binde, BioSqueeze’s marketing and sales support manager.

So far, the testing has been confined to deep sand boxes soaked with Biosqueeze’s proprietary mix of chemicals plus a common variety of soil bacteria which serves at a catalyst to create calcium carbonate—the primary component in limestone—to test whether it can meet military specifications.

To get to the field testing, BioSqueeze will have to show the material can do the job and also develop the equipment needed to build a road or a runway with it.

“The biggest part of the job now is developing the specific equipment for these applications,” Binde said.

In an oil well, BioSqueeze injects small volumes of the fluid mix that follow leak paths, which are usually fractures too small for cement or other leak-stopping materials to enter.

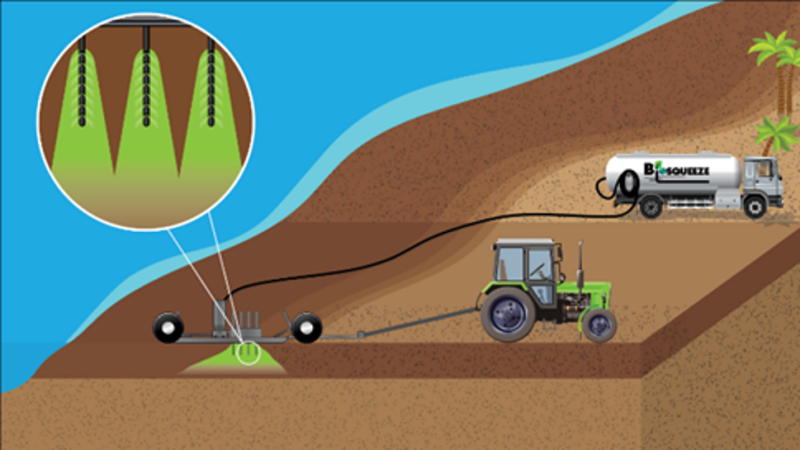

For field testing they are thinking about using modified farm equipment to control how much fluid is sprayed on, then till the soil to ensure the treatment gets deep enough to build a thick, strong surface.

The Air Force contract requires patching craters on battle-damaged runways. BioSqueeze needs to show its material can bond to the irregular edges created by a bomb blast. Binde said they do not expect that to be an issue because the bacteria create “a biofilm which by nature is sticky.”

Remote road building will require a supply of bacteria on demand, using durable equipment that is simple enough to be operated by soldiers on site.

BioSqueeze uses a strain of soil bacteria that can remain dormant during storage. When needed, soldiers will need to be able to reactivate the microbes and use an on-site bioreactor to multiply the microbes to the scale needed for the job.

When developing technology for the DoD, there are no guarantees. The $1.2-million contract with the Air Force is for the first 2 years of work. If this year’s work goes well and the problem it addresses remains a priority, the military may fund field testing.

If it clears all those hurdles, BioSqueeze hopes to use what has been learned to seek out commercial as well as miliary applications. In the oil industry, uses could include road building in remote places, well construction for new wells, or the life extension of older ones.