Unlike new-drill wells, refrac wells don’t offer operators any flexibility on drilling location or where to land a lateral. These factors are already decided, which makes the keys to success twofold: picking the right refrac candidates and executing them with minimal operational risk.

With over 300 refracs under our belt, Vertice Oil Tools has had a front-row seat to the evolution of refrac technology and its significant impact for operators in the Lower 48 states.

Our journey with refracs, specifically mechanically isolated, or “ISO refracs” as we call them, started in 2018 in the Eagle Ford Shale and now includes over 100 patents and patents-pending, a quarter of which are specific to our refrac technology.

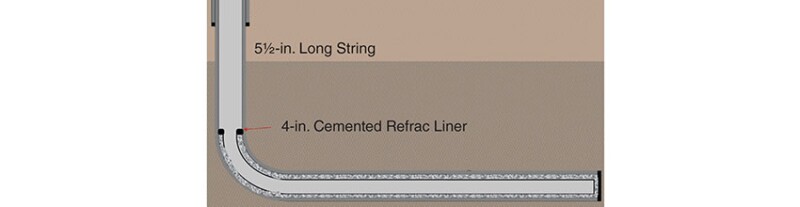

When we entered the market, operators were beginning to test refracs by cementing 4-in. casing inside of 5½-in. casing and then refracturing. Many of these first refrac pilots faced challenges. Oftentimes, the candidate selection might have been optimal, but the operational risk was high.

Refrac liner systems and other refrac tools have since matured and offer greater operational reliability along with lower costs.

At the same time, merger and acquisition activity in the tight-oil and gas industry has picked up as operators move to build up their inventory of new drilling locations. But one other driver that is emerging from the dealmaking is extracting more barrels from existing assets through refracturing.

At Vertice, we have identified what we believe to be almost 10,000 Tier 1 wells that are potentially prime candidates for refracturing. If properly executed, we estimate that refracs of these wells could generate more than $50 billion at a net present value at a 10% discount rate, or NPV-10.

At current commodity prices, the NPV-10 of a Eagle Ford or Bakken Shale refrac well is typically between $3.5 to $4.0 million with a payback between 1 to 2 years.

Given the fast cycle times of the shale sector, initial rates of return on refracs are also often north of 100%. With such returns, which often exceed those of new wells, refracs have increasingly become a key strategy for operators, and activity is expected to more than double this year.

With ISO refrac activity also expected to more than double this year, we believe the market is poised for continued growth.

While the Eagle Ford remains a hotspot, activity in the Bakken is catching up, and we believe other maturing basins will follow the trend as drilling inventory shrinks and refrac costs continue to drop.

We also see the industry moving towards more sophisticated refrac techniques, including protective refracs, where a refrac well is treated alongside newly stimulated wells on the same pad to achieve cost efficiencies and mitigate frac hits.

Understanding Refrac Candidate Selection

Refracs are gaining traction because they allow operators to enhance production from existing wells, leveraging known geology and established infrastructure. This reduces risks and costs compared to drilling new wells.

However, the past several years have also shown that the success of a refrac campaign depends heavily on selecting the right candidates.

There is a laundry list of factors to consider when evaluating candidates: rock quality, vintage, lateral length, stage spacing, offset distance, relative performance, fluid and proppant intensity, etc.

This said, the two biggest deciders of an ideal candidate tend to be those with good rock quality and the oldest vintage. Typically, that means wells drilled between 2008 and 2016 are considered “prime” candidates.

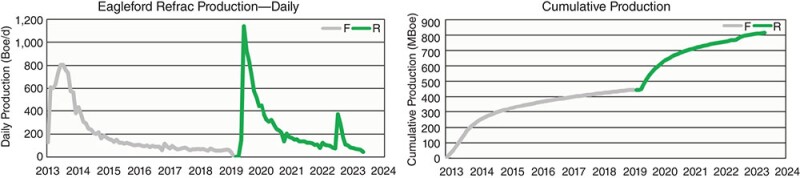

These early-generation wells often have suboptimal completion designs, making them ideal for a refrac completion. For example, in the Eagle Ford, wells with suboptimal primary frac jobs (i.e., less than 1,000 lbs/ft of proppant) but with excellent reservoir characteristics, have shown remarkable post-refrac production improvements (Fig. 1).

These insights are based on 6 years of field experience and an in-house comprehensive database of refracs and refrac simulator that we use for candidate selection. Our simulator analyzes and interprets historical well data to forecast refrac production and unit economics. Trained on approximately 600 mechanically isolated refracs, we have backtested the technology to help operators identify wells with the highest likelihood of success and best returns.

You Picked the Candidate Wells, Now What?

After selecting refrac candidates, your next step is to decide how to refrac them. There are two popular methods to choose from: bullhead refrac (also known as a “pump-and-pray” refrac) and mechanically isolated refracs, or ISO refracs.

Pump-and-pray refracs are still done today by some, but we argue that the consensus view among most operators involved in this space is that ISO refracs are the optimal approach for effectively restimulating an entire lateral section, which results in higher production uplift.

The attraction to bullheading stems from the low cost of pumping into an unisolated wellbore. And while that means ISO refracs come at a higher cost than the pump-and-pray approach, they also offer higher rates of return on average and are easier for operators to predict.

This brings us to the topic of cost efficiency, which is a major deciding factor for many operators.

This is also a factor that has shifted. If you tuned in a few years ago, you would have considered the cost of refracs as the chief barrier to adoption. But recent innovations in refrac liner equipment along with improved operational practices have lowered the costs by a significant margin.

With the new advancements and more streamlined processes, we have seen ISO refrac costs drop on a per-well basis from upwards of $6 million to as low as $2.5 million. This more than halving of costs is potentially a tipping point for the refrac market which must compete with new wells for capital.

Evolution of Mechanical Isolation Refracs

The most common refrac well architecture today is 4-in. casing inside of 5½-in. casing in the Eagle Ford (Fig. 2) and 3½-in. casing inside of 4½-in. casing in the Bakken.

Initially, liner systems and refrac tools were very limited in these sizes which meant operators had to resort to other methods to execute refracs.

Two common ways were to use expandable liners or run a long string of casing and then use intervention methods to cut the uncemented portion of the casing and retrieve it prior to the refrac. The ad hoc solutions were not necessarily low cost and proved to be complex, required significant well prep time, and introduced their own operational risks.

More recently we have seen the use of refrac liner systems and packers become standard practice in these specific well architectures to optimize refrac operations.

Purpose-built refrac liners designed for refrac well architectures significantly lower the number of days spent on a well and reduce operational complexity.

Operational Learning Curve

One of the biggest challenges operators run into when starting up a refrac program is the operational learning curve and knowing how to avoid the common pitfalls.

This applies to ISO refracs in that they are one of the few downhole approaches that require experience from most of the key engineering disciplines, including production, workover, drilling, and completions.

The first step of an ISO refrac is cleaning out the well. Thorough wellbore cleaning and preparation are crucial steps that, if inadequately performed, can lead to costly operational issues down the line.

The second step is to run refrac casing or a refrac liner into the well, followed by cementing it in place.

The final step is the hydraulic fracturing treatment. Standard practice involves a “plug-and‑perf” completion, similar to that of a new well. Leveraging the insights of in-house expertise as well as the experience of refrac service providers is also important to ensure operations run smoothly.

In sum, nothing is ever a “sure thing” in this business, but with careful candidate selection and the right operational execution, refrac outcomes can be predictable and significantly enhance production from existing wells at a fraction of the cost of new completions.

Alex Goodwin is the vice president of sales and operations at Vertice Oil Tools and has more than a decade of experience in the oil and gas industry. Based in Houston, Goodwin has held key roles at Vertice since 2018 and was previously a global account manager for international drilling contractor Nabors Industries. At Weatherford he was involved in the Sakhalin Island project. His career began at Shell Oil Company as an intern. He holds an MBA in finance and marketing and a BS from Louisiana State University.

Alex Nguyen is the chief financial officer at Vertice Oil Tools, a position he has held since March 2018. With a background in finance and investment, Nguyen has been pivotal in steering the financial strategy of Vertice. Previously, he served as an analyst at Citadel Investment Group, where he honed his expertise in financial analysis and investment strategies for nearly 6 years. His career also includes significant roles at Lime Rock Partners as an associate and at Simmons & Company International as an analyst. Based in Houston, he holds a master’s of professional accounting (MPA) degree and a bachelor’s degree in business administration (BBA) in accounting and finance, both from The University of Texas at Austin McCombs School of Business.