The hydrogen economy could be a boon to the oil and gas sector in numerous ways. “Supplying hydrogen could potentially become a huge new market that oil companies could dominate quickly thanks to their existing expertise in transporting and selling gas,” said Bloomberg-NEF in a recent report.

The scale and cost advantage of H2 production from fossil fuels today suggest that a major fraction of hydrogen production in the near term will come from fossil fuels with carbon capture and storage (CCS) to achieve decarbonization. Blue hydrogen is not only an easier way to pivot to clean energy than going full-on renewables; it could also establish new businesses and generate tremendous revenue by leveraging the industry’s knowledge and expertise in geoscience, chemistry, materials science, and drilling and production.

“It’s a way to avoid having stranded assets from the current fossil-fuel-based system,” said Pierre-Etienne Franc, who leads hydrogen projects at French chemical giant Air Liquide.

“We’ve built this competence over decades,” said Steinar Eikaas, vice president of low-carbon solutions at Equinor. “If you want to store CO2 safely, there is no other industry but oil and gas that can do it.”

Equinor is participating with Vattenfall and Gasunie to convert Vattenfall’s gas-fired power plant in the Netherlands to run on blue hydrogen. When it opens, the plant will replace carbon emissions with water vapor, which could reduce Dutch CO2 emissions by up to 4 million tons per year. The partners expect the first of three units at the plant to be converted by 2023. Equinor will supply the hydrogen needed to operate the plant’s turbines and will store resulting CO2 in underground facilities deep in the Norwegian North Sea, where it has stored captured CO2 from the Sleipner field for more than 20 years. Equinor is also a key participant in numerous other projects in the Netherlands and the UK.

BP and its solar joint venture Lightsource BP are exploring a potential 1.5-GW wind-and-solar powered plant in Australia that will convert green hydrogen into "green ammonia" and be exported internationally. A pilot phase would produce 20 kilotons annually (ktpa), with the full-scale commercial operation producing 1,000 ktpa of green ammonia. BP is also pursuing hydrogen projects in some of its refineries. In 2018, the company’s Lingen refinery in Germany became the world’s first to use green hydrogen from water electrolysis to meet a portion of its hydrogen demand.

Neptune Energy and Eneco are partnering on the PosHYdon pilot, the world’s first offshore green hydrogen plant, in the Dutch sector of the North Sea. In the pilot, electricity from offshore wind farms 25 km north of the Neptune-operated Q13a platform could ultimately power hydrolysis, in which seawater is converted into demineralized water and then into clean hydrogen. The green hydrogen will be pumped onshore over existing pipelines as far as northern Germany.

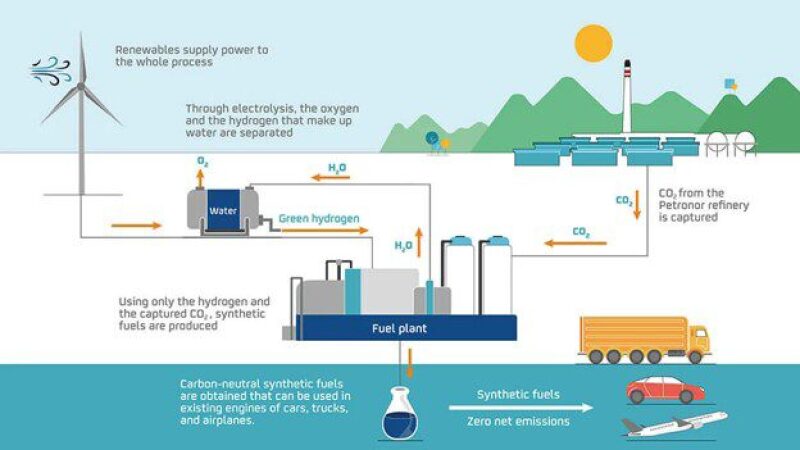

Repsol announced plans in June to build one of the largest net-zero-emissions synthetic fuel production plants in the world, based on green hydrogen. The Spanish facility, which is expected to be fully operational in 4 years, will combine green hydrogen with CO2 captured from the nearby Petronor refinery as the raw materials in the process.

Shell is developing hydrogen stations in the UK, the Netherlands, and Canada. The company began feasibility work in February with Gasunie and the Port of Groningen on NortH2, which could become the largest green hydrogen project in the world. Plans call for 3 to 4 GW of offshore wind capacity to be established in the North Sea by 2030 purely for the purpose of manufacturing green hydrogen and could be expanded to 10 GW by 2040. Electrolyzers will be based in Eemshaven on the Netherlands’ north coast, and potentially offshore. Shell also has four hydrogen filling stations in California and is partnering with Toyota, with the support of the State of California, to further develop its hydrogen refueling network.

Read more in: