The migration to ultra-mature production and concern about rising greenhouse gas emissions mean that the implementation of carbon capture and storage projects are coming into sharper focus than ever before in the Middle East.

Capturing carbon dioxide (CO2) and using it in enhanced oil recovery (EOR) is one strategy being widely adopted. Studies showing the region having one of the world’s highest per capita environmental footprints have led governments to look for ways to improve their rankings in greenhouse gas emissions.

So far, Oman is the only country in the region to have launched EOR programs on a large commercial, rather than pilot, scale in a bid to stem and reverse years of declining crude production. In Abu Dhabi, tertiary gas injection has been under way for decades at the Total-operated Abu Al Bukhoosh field with great success. As production in the region matures, more countries are expected to implement EOR programs.

The application of CO2 EOR provides two advantages for companies in the Middle East. It allows natural gas that would otherwise be used for injection into oil fields for secondary recovery to be freed up to meet domestic requirements, such as power generation and industrial use, or to limit the costly import of liquefied natural gas. Moreover, it helps limit emissions in the region.

The oil and gas industry is using technology for mapping oil and gas fields to find sites suitable for CO2 storage. The most effective way to ensure permanent, safe storage is to choose sites of sufficient depth (typically deeper than 800 m) with adequate capacity and an overlying sealing system to ensure containment.

Currently, there are 23 active and 53 planned carbon capture and storage (CCS) projects worldwide. They include Sleipner and Snovit in Norway, Weyburn and Zama in Canada, K12b in the Netherlands, Blue Lake in the United States, and Ketzin in Germany. In Salah in Algeria was recently suspended because of leakage.

UAE: CCS as a Necessity

The UAE grapples with the challenges of managing soaring domestic energy demand and meeting ambitious clean energy targets laid out in its National Vision 2030. The government has said that CO2 injection by EOR soon will become a necessity rather than an option for the country. At the Abu Al Bukhoosh field, EOR by tertiary gas injection was deployed about 20 years ago. But now, with a tightening gas supply-demand balance and the obligation to reduce its carbon footprint, the UAE is looking actively for CCS projects, which will be costly given the infrastructure needed to be put in place in the initial project stages.

A key issue facing Abu Dhabi is the lack of clear pricing for carbon. That led to the collapse of a CCS project planned by BP and Masdar in 2010, which was to produce CO2 for injection into oil fields from a hydrogen-fueled power plant, after Masdar and Abu Dhabi National Oil Company (ADNOC) failed to agree on a carbon price. From ADNOC’s perspective, the problem was clear: Why pay a higher price for CO2 for injection when it was cheaper to use subsidized conventional natural gas instead.

But the economic value of EOR and CCS projects is changing. Abdul Munim Saif Al-Kindy, chief executive officer of Abu Dhabi Company for Onshore Oil Operations (ADCO), said that carbon sequestration for EOR will likely play an increasing role in the company’s onshore development program. “If we can technically assert the value of CO2 in terms of enhanced oil recovery, then we may start a much wider EOR scheme at one of our major fields by 2016,” he said recently.

In January, Maersk signed a memorandum of understanding with Masdar to collaborate on carbon capture. Through this deal, Maersk hopes to bring its TriGen technology, a form of carbon capture technology that generates water and power in addition to carbon dioxide for injection into oil reservoirs, to the emirate, which is seeking projects to help boost oil production capacity from under 3 million BOPD to 3.5 million BOPD.

In addition to the Maersk project, Masdar Carbon, one of the five integrated units of Masdar, and ADNOC announced in November 2013 that discussions on a carbon capture (usage and storage) facility adjacent to the Emirates Steel complex at Mussafah have produced an agreement allowing the project to proceed to tender. The carbon capture facility is part of a collaboration between Masdar and ADNOC to explore the feasibility of joint projects to reduce the carbon footprint of the emirate and make available CO2 for EOR operations in the future. A CO2 injection pilot project on EOR at an onshore field 2 years ago and the data collected over the period encouraged the two partners to go ahead with the Emirates Steel project.

In the next stage, Masdar intends to issue requests for proposal for the facility that will capture nearly 800,000 tonnes per annum of CO2 prior to emission from the Emirates Steel’s Phase 1 and Phase 2 lines. The CO2 feed stream from the Emirates Steel plant, containing 90% of CO2, will be transferred to a common compression and dehydration facility at the project site in Mussafah. The feed stream will be compressed, delivering a CO2 stream of more than 98% purity, and will be injected in an onshore field operated by ADCO.

“This carbon capture usage and storage project can have upside potential and bring additional benefits to the emirate of Abu Dhabi in the long term if the CO2 pilot proves to be successful as an EOR mechanism,” said Mohamed Butti Al Qubaisi, E&P director of ADNOC. “We are keen to move ahead to better realize the mechanisms of CO2 injection and production in our fields.”

ADNOC, the parent company of ADCO, also plans a carbon dioxide conversion project in Al Rumeitha in 2015, a carbon dioxide project in Bab field in 2015 and one in Bu Hasa in 2018, and an offshore carbon dioxide project in LZ in 2020.

Saudi Arabia: A CCS Road Map

Saudi Aramco is currently evaluating the use of CO2 injection and has planned a series of pilot programs in mature fields such as Ghawar. Although full-scale EOR implementation is still 20 to 30 years away, the feasibility studies form part of Saudi Aramco’s carbon management road map, in which it wishes to be engaged in developing EOR technology for global carbon management.

Saudi Aramco plans to inject 40 MMscf/D in the Uthmaniyah area of its largest oil producing field, Ghawar, beginning this year. Saudi Arabia is a long-standing member of the Carbon Sequestration Leadership Forum (CSLF), a ministerial-level international climate change initiative focused on the development of cost-effective technologies for the separation and capture of CO2 for transport and long-term safe storage.

Regarding the need for EOR, Saudi Aramco believes that careful reservoir management, new drilling technology, and state-of-the-art information gathering can significantly extend the conventional production life of many of its fields.

King Abdullah University of Science and Technology’s Global Research Partnership, along with Cornell University, is funding a USD 25 million Center for Energy and Sustainability, which will focus research on the use of organic and inorganic nanoparticle materials and their applicability to CCS and other uses.

Kuwait: Looking for Recognition

Kuwait’s first CCS projects began in 2012 and include a plan to capture 450 tons of carbon dioxide daily from its existing facilities. Equate Petrochemical, a venture of Dow Chemical and Petrochemical Industries of Kuwait, are the operators.

In addition, Kuwait Oil Company and the Kuwait Institute for Scientific Research have a joint research project for assessing CO2 hydrocarbon injection projects for EOR application in Kuwaiti reservoirs. And Japan Oil, Gas and Metals National Corporation signed a memorandum of understanding with Kuwait Petroleum Corporation to cooperate in a joint research project on CO2 enhanced oil recovery.

Qatar: CCS R&D Institute

Qatar has several CCS-related initiatives:

- Qatar has pledged USD 70 million for an R&D project related to CCS, which is part of its efforts to reduce CO2 emissions. The 10-year project will explore new storage technologies for CCS and is a collaboration of Shell, Qatar Petroleum, Qatar Science and Technology Park, and Imperial College London.

- Since 2005, RasGas, through its acid gas reinjection program, reinjects about 1 million tonnes of CO2 every year into saline aquifer formations.

- Oryx GTL is funding and providing expertise to support the Gas Processing Center’s CO2 capture research project titled “Process Development for CO2 Capture: Bench Scale Tests of Selected Chemical Solvents,” which will evaluate the performance of different chemical solvents in capturing CO2 from the flue gas of natural gas-fired power plant.

Algeria: Rethinking CCS

Algeria was one of the leading countries in deploying a commercial CCS project through the In Salah Gas (ISG) project in Algeria, which was the first industrial-scale CO2 storage project in the region. It was in operation from 2004 to 2012, but the project was shut down because of leakage.

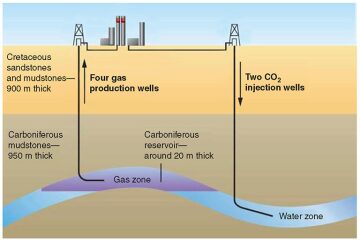

In the project, CO2 from several gas fields, which had a CO2 content of 5% to 10%, was removed from the production stream to meet the sales gas export specification of 0.3% CO2. Rather than venting the separated CO2 to the atmosphere, BP and its joint venture partner, Sonatrach, invested in a project to compress, dehydrate, transport, and inject the CO2 into a deep saline formation. Statoil joined the venture at production startup in August 2004.

The CCS at the ISG project had been active at the Krechba gas field in Algeria between 2004 and 2012. “By the end of 2011, over 3.8 million tonnes of CO2 had been securely and geologically stored in a deep saline formation,” said Fayçal Selama of Sonatrach during a recent workshop in Kuwait.

The site has been identified by the CSLF as one of three industrial-scale monitoring and verification demonstration sites worldwide. But in 2010, a seismic survey and risk assessment signaled a high probability of CO2 injection-induced fractures and that the continued high-rate injection could lead to leakage. Injection stopped shortly thereafter. Sonatrach and the Algerian Ministry of Energy and Mines are assessing future CCS projects.