The complete paper discusses the natural-gas-dehydration performance of dehydration units in two different plants using a preinhibited glycol/antifoam/pH adjuster blend vs. neat glycol with periodic injection of antifoam and pH-adjuster inhibitors. The insights made with this new preinhibited-glycol-blend approach present an opportunity for significant reduction in both operating and capital costs for existing and future gas-processing plants as well as a decrease in corrosion rates with prolonged plant life.

Introduction

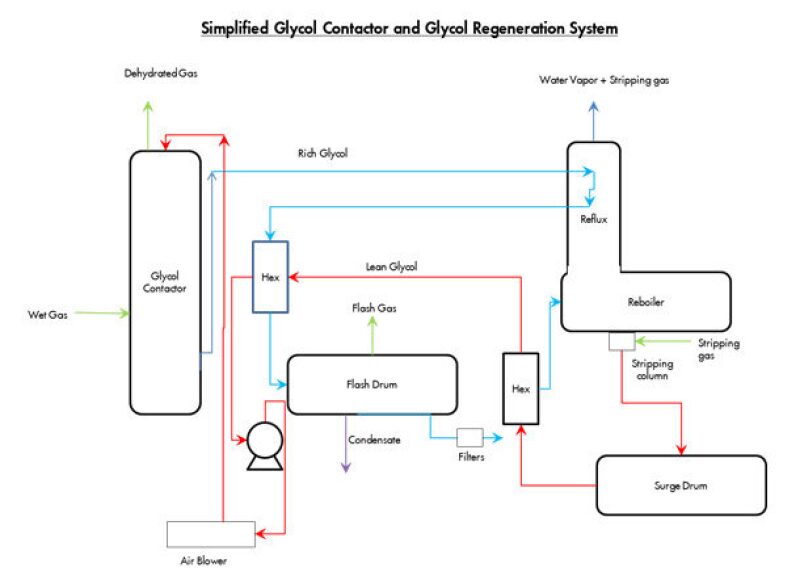

The use of triethylene glycol (TEG) to strip gas of its water content in an absorption tower (known as a glycol contactor) has gained prominence in the industry. This is because glycol can be regenerated and recycled back into the contactor, making it less operating-expense (OPEX)-intensive. However, this system is not without its disadvantages.