As a rule, when it comes to evaluating models of how carbon dioxide (CO2) will behave after it is injected into a formation, beware of a “geologic model that looks like a layer cake.”

That advice was offered by Amanda Livers-Douglas, assistant director for integrated subsurface projects at the Energy & Environmental Research Center (EERC) at the University of North Dakota. She explained that models where “all the layers are homogenous” are a red flag because geology is rarely consistent.

It’s hardly news to petroleum engineers that reservoir models fail to convey where gasses will flow in the formations full of features that regularly do not show up in seismic and other tests. What is new is the sort of trouble that can be associated with getting that wrong in a CO2 storage project.

“When you start operations, if the gas finds an undetected high-permeability channel, the plume will act differently than predicted,” she said during a presentation at the recent CO2 Conference in Midland, Texas.

This becomes a problem for a storage project if the plume migrates into pores that were leased for storage.

In North Dakota, the worst-case scenario is “you may be in noncompliance of your permit and have to stop injection” because it has invaded pore space not leased for the project.

What is more likely gets complicated. North Dakota’s regulations set a process that anticipates this problem and the procedures for monitoring and permit modifications when storage sites grow outside the lines. Changes require public hearings “where the developer could face new opposition to the project from pore space owners and the public,” Livers-Douglas said.

Outside of North Dakota, which is one of the few states with a law covering subsurface units created for storage, plume growth outside the leased area can create a cloud of uncertainty over the project.

Based on long experience in CO2 enhanced oil recovery (EOR), runaway injections can lead to conflicts with neighbors with subsurface rights, such as lawsuits from nearby natural gas producers who are paying to remove rising levels of migrating CO2 from their production.

The factors that bedevil those predicting plume growth can also lead to problems in predictions of key project variables such as the expected gas-injection rate and the total storage volume.

Where Will It Go?

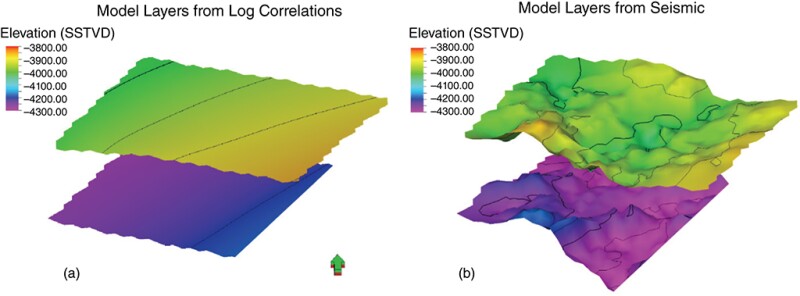

A recent CO2 plume-modeling project done at the EERC shows how more data can drastically change what is expected after large volumes of gas are injected.

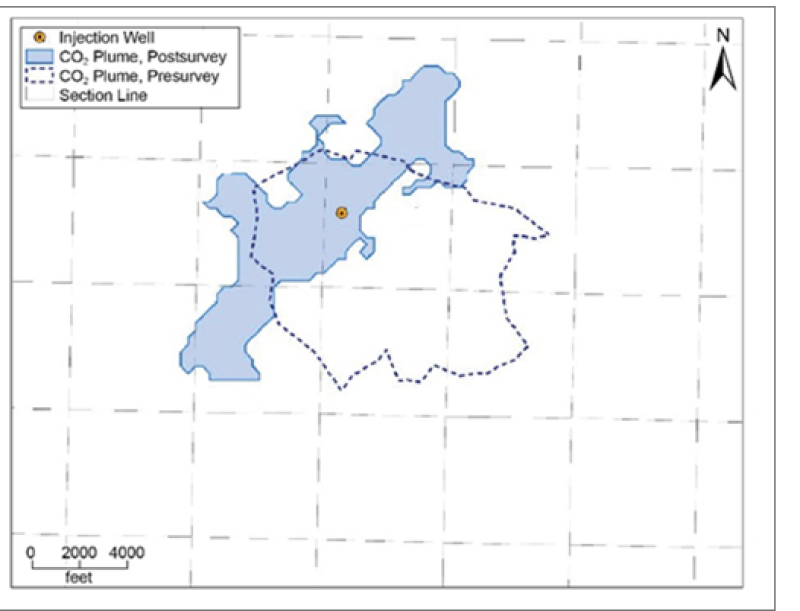

The initial evaluation based on downhole logs from nearby exploration wells predicted the injected gas plume would fill the area bounded by the dotted blue line.

When seismic data plus well log data were modeled, the result was an elongated blue area which extended well outside the boundaries of the previous run, shown as the solid blue area in Fig. 1.

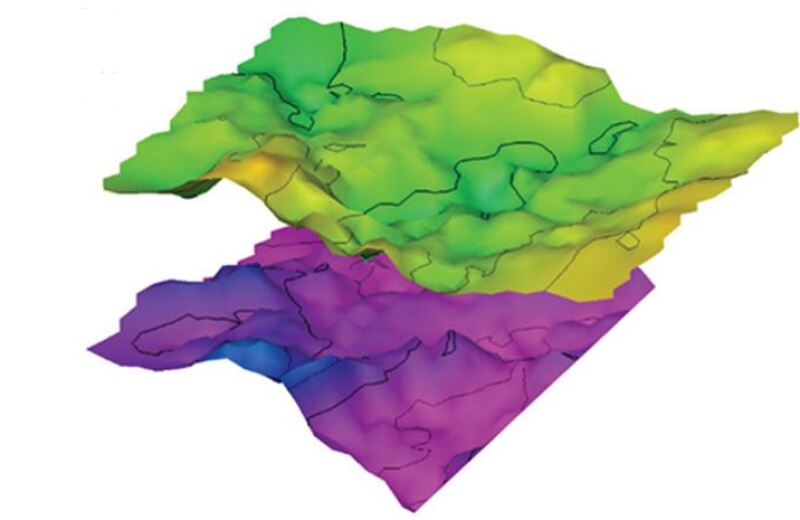

Seismic data, shown in Fig. 2, changed the picture by revealing far more vertical variation in the subsurface layers. When that data was added, the model predicted the plume would rise up to a structural high, said Livers-Douglas.

When asked which of those is correct, she said it was likely somewhere in between the two. She would advise the developer to treat the second model as a worst-case scenario when planning the project.

There is no way to be sure which is correct without injecting the gas, which isn’t going to happen in this case because the developer moved the project to a location a few miles away. The new location has fewer of the subsurface elevation variations that caused so much uncertainty at the first location, she said.

Plume modeling is an emerging challenge for geoscientists and petroleum engineers, and there is a limited amount of storage data to rely on.

While a lot has been learned from EOR, there may well be significant differences between cycling just enough gas through a reservoir to increase production and injecting as much gas as possible for permanent storage, often in unfamiliar sorts of formations.

CO2 Is Tricky

All of the above argues for paying for extensive downhole data and analysis when planning a project. But there will always be uncertainty in these predictions, so it is wise to acquire pore space rights over a large enough area to build in a margin for error, Livers-Douglas said.

“It’s really hard with 3D seismic to detect all the baffles or barriers that can influence gas migration,” she said.

When the gas is being stored in depleted oil and gas fields, the production data can offer valuable details about the reservoir structure. In North Dakota, though, the storage projects are injecting into saline aquifers outside the heavily drilled Bakken play.

The locations below industrial facilities where the CO2 is captured save a lot of money and trouble associated with pipeline building but lack the oilfield production data that can provide valuable clues about reservoir performance.

Even a well-known, closely examined formation can surprise. Another presentation at the CO2 Conference described the unexpected growth of the CO2 plume at the Snøhvit Field offshore Norway. The surprise occurred despite a thorough planning process that used an unusually long list of pre-injection diagnostics in an area near a large offshore field.

The unexpectedly wide spread of the CO2 threatened to contaminate a nearly producing gas field. Carbon dioxide injection at the site has since been shut down.

Based on the experience, Philip Ringrose, adjunct professor at the Norwegian University of Science and Technology, advised the audience to “expect surprises when you start injection.”