Risk is inherent in all field development plans. Much of the risk is related to the uncertainty in the reservoir characterization and its effects on production forecasting and, ultimately, facility design. Improper management of subsurface uncertainty in the field development plan and facility design process is often a reason for project difficulties, including cost and schedule overruns, and the failure of projects to meet their production and economic objectives.

The term “uncertainty” is used in this article to describe data that is subject to change and refinement during appraisal work and engineering, and should not be confused with the inherent uncertainty in the reservoir data (i.e., the mathematical definition of uncertainty). The inherent uncertainty can be resolved to some extent, but can never be eliminated because of the reservoir’s geological conditions, such as heterogeneity.

Uncertainty in reservoir data affects well construction, completion design, risers and flowline specifications, processing facility designs, production operations, and reservoir management after first oil. Facilities engineers are tasked with designing and building robust production systems, comprising separators, compressors, pumps, heat exchangers, and other process equipment, that allow adequate flexibility to accommodate a spectrum of production fluid compositions and conditions over the life cycle of the field.

The early project planning phases include feasibility studies, concept development, strategy evaluation, and pre-engineering. Reservoir uncertainties play an important role in all stages of field development and facility planning. Fig. 1 shows other uncertainties that affect the early project phases.

Gu and Gudmestad (2012) describe four technical uncertainties that affect the early phases of planning:

- Concept uncertainty affects choices for optimal field development, such as type of platform (floating or fixed) and production capacity.

- Design uncertainty encompasses variations in loading conditions, modeling assumptions, and material properties.

- Technological uncertainty includes variables such as access to new technologies, development costs, and maintenance.

- Operational uncertainty results from the operating system itself, or the operator.

Going by the Numbers

The challenges of integrating the work of facilities and reservoir engineers to manage the uncertainties in design data arise from their differing views on quantifying reservoir characteristics and production forecasts. Facilities engineers tend to work in a realm of deterministic or point values and limited ranges, whereas reservoir engineers tend to work with probabilistic estimates with wider ranges.

John Vitucci, field development manager at Granherne, said, “Building the communication between the subsurface experts and the facilities engineers to define the ranges or point values to accurately reflect a wider range of reservoir values is not so much a method as it is a workflow and communication process between the two groups.”

He said there is a wide range of communication effectiveness in the industry, often related to the size of the project and the type of companies involved in the project. “The number of facility designs and adjustments provide an indication of how effectively the reservoir and facilities engineers are communicating during the early planning phase, and how the understanding of the subsurface data is evolving compared with when the facilities design was started,” Vitucci said.

Fast-tracking of projects initiates the design of facilities earlier in the process when the reservoir and subsurface data are still being developed, and “that creates issues, because we are trying to take data with large ranges and uncertainty that could be subject to future changes and trying to narrow them down to a limited range or point value to proceed with facilities design,” he said.

Reservoir and asset integration modeling provides guidance for early planning, but these models are only as good as the data upon which they are based. “How much confidence do we have in the data that are being used in the model and are the data subject to change as the project proceeds from preliminary design to detailed engineering is a key question,” Vitucci said.

Understanding the model’s parameters and their complexity is important for reservoir and facilities engineers. The challenge for facilities engineers is to design facilities that are flexible enough to handle an envelope of production conditions, rather than a limited production scenario.

The level of definition for subsurface design data differs among companies and projects. Probabilistic production forecasts, P10, P50, and P90 values, supported by extensive appraisal data and reservoir modeling may be used for a particular project. Other projects may use one or two production cases based on a preliminary reservoir management plan and supported by limited appraisal work. The level of definition is based on the amount of subsurface appraisal work, fluid characterization, and reservoir modeling performed by the operator. Vitucci said facilities engineers must understand the need to keep design options open in the event of changes to the subsurface information, production forecasting, and reservoir management plans.

“I think the idea of dynamic design data sometimes gets lost when we go from fixing the design basis to executing the design. We start designing the facilities and then the data starts to change. All the models and engineering techniques in the world have a difficult time managing that without effective communication between engineers and having a method to incorporate those changes into a design in a systematic manner.”

To manage the workflow and communication of a project, Granherne uses a system engineering and requirements planning methodology to identify and rank data uncertainties, their effects on facilities design, and estimate the timing for their resolution. The information is provided to the engineering teams on an ongoing basis, said Vitucci.

Vitucci said how uncertainty in design information is handled depends on a company’s culture and constraints. “As a general observation, companies trying to fast-track projects have more difficulty in identifying and incorporating changes in design data and managing the increased level of risk introduced. Companies with the capability to adjust the project time horizon can more effectively deal with such change and managing the associated risks. Larger companies with a portfolio of projects tend to have more ability to adapt by reprioritizing schedules, learning from other project teams, and adopting alternative design strategies.” Such strategies include:

- Adjusting the overall project schedule to take the uncertainty into account and manage it at a different risk level.

- Basing decisions on the current state of knowledge and future appraisal plans, companies develop scenarios and work plans to address the uncertainties and risks, and then select an optimal plan.

- In projects constrained by commitments or hard completion dates, companies must sometimes accept the uncertainty and risk and deal with it as the project proceeds. This often leads to an overly conservative design.

During SPE’s “Bridging the Gap Between Reservoir Engineering and Facilities Design” workshop, held last year in San Antonio, Texas, engineers wanted to know how to resolve the uncertainty in the data, Vitucci said. “We’ve been battling this issue for 100 years in producing oil and gas. We’re not going to be able to resolve the uncertainty. Information and our understanding of that information are going to change. What we can do is manage the uncertainty,” he said.

Deciding When to Pay for Data vs. Flexibility

Fast-track projects are a necessity for operators in some cases. Moczydlower et al. (2012) described how the complexity of assessment and management of subsurface and other uncertainties requires a systematic approach to determine the value and cost of planned designs.

The authors also address the decision-making process in selecting design options: When is it justifiable to pay for additional information before committing to a design vs. paying for the incorporation of flexibility in the design? Factors such as specifying and anticipating the acquisition of expensive equipment, such as subsea devices and floating production, storage, and offloading (FPSO) vessels, deciding whether investment is warranted in additional data acquisition from extended well tests, core and fluid sampling, laboratory analysis, or more appraisal wells, influence a company’s decision.

The timing and the foreseen reduction in uncertainty for each initiative must be assessed. Alternatively, it may be better to pay for extra flexibilities, accepting the increase in capital expenditure. Examples of options to provide flexibility are smart completions and the possibility of injecting chemical products into the wells; separated gas and water lines for each satellite injector; subsea layout; allowing multiple strategies and the addition of more wells; and FPSOs designed to inject desulfated water, or to export, import, or reinject the gas.

The Santos Basin pre-salt cluster (SBPSC), located offshore southeast Brazil, posed development challenges to Petrobras. For example, its fluids have variable carbon dioxide (CO2) content, and the few analogue reservoirs around the world do not have comparable volumes, water depth, or distance to shore.

The authors cite the importance of the reserves to the Brazilian economy and the opportunity to accelerate cash flow as factors in the decision made by Petrobras and its partners to fast-track the SBPSC development. Petrobras forecasts its share of the production to be more than 500,000 BOED in 2015 and more than 1.1 million BOED in 2020.

The oil accumulations are located approximately 300 km from the shore in water depths of 2200 m, and reservoir depths are between 5000 m and 6000 m below sea level, under a salt layer that may reach thicknesses of up to 2000 m.

Oil properties are API gravity between 28 and 30 and gas/oil ratio (GOR) between 200 m3 and 350 m3. The pressure gradients tend to be more than 0.1 (kgf/cm2)/m, and because of the thick salt layer, the temperatures tend to be low.

During the initial development phase, subsurface uncertainties include:

- Quality and heterogeneity of each carbonate reservoir zone

- Compositional grading of fluids

- Performance of enhanced oil recovery methods

- Presence of fractures that affect the flow

Methods planned for use in the recovery of the oil are waterflooding, gas injection, and possibly water alternating gas (WAG) methods.

Strategies for Coping With Uncertainties

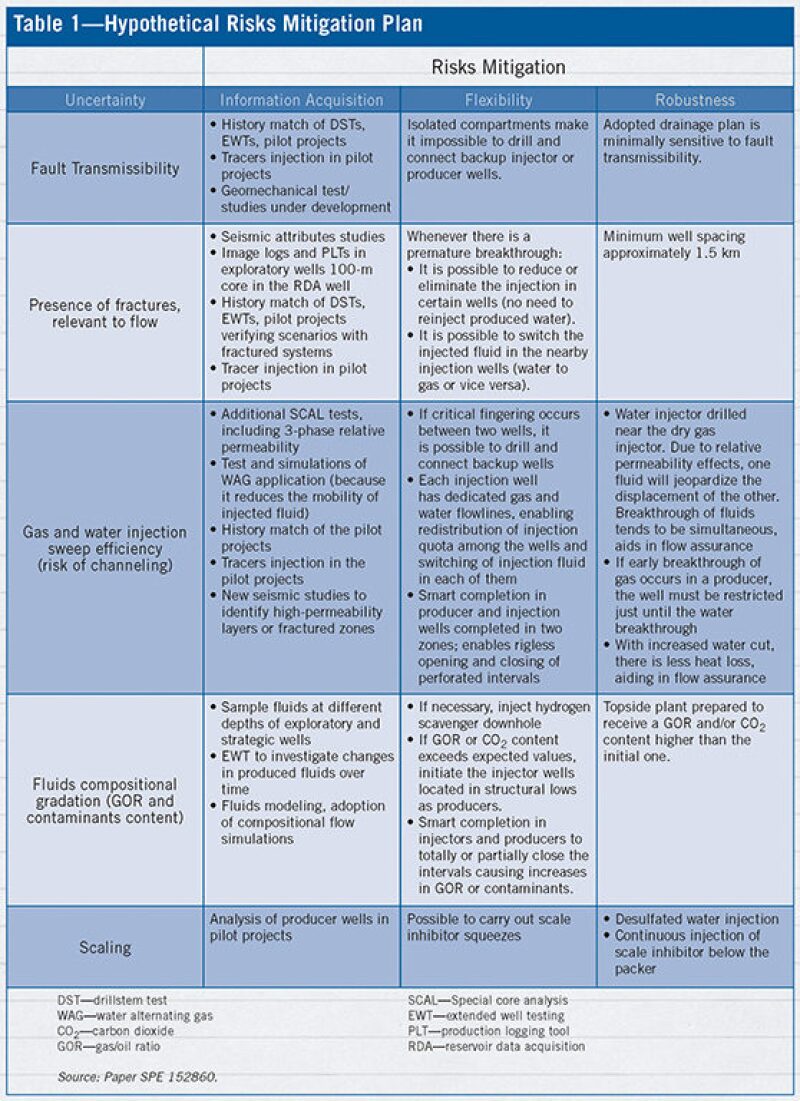

Moczydlower et al. define three alternative or complementary strategies to deal with the SBPSC uncertainty:

- To be robust—adoption of a solution that is strong enough to cope with a variety of scenarios. In cases with reservoir volume uncertainty, a medium-size installation may be the best option to reasonably comply with most of the cases, even if a medium-size volume is not the most probable scenario.

- To be knowledgeable—gathering of more data to reduce the uncertainty before making decisions by adding reservoir data acquisition wells or seismic surveys. Because of the cost associated with the methods used to gather information, the authors recommend computing the value of information (VoI) before deciding to proceed. The VoI is the difference between the expected mean value of two robust optimizations, one with more information and the other with less information. The VoI may be less than the cost of acquiring the information. In such cases, it is unreasonable to pay for additional information. While computing the VoI is becoming a common practice, it is often difficult to think of all relevant uncertainties and to assign their probabilities.

- To be flexible—creation of flexibility that can be used to react to uncertainties as they manifest during the development or operation phase. The design is adapted to allow future capacity expansion, drilling options, and application of recovery methods at affordable additional costs. The system is designed to delay its final configuration until future needs are determined.

Moczydlower et al. highlight the difference between risk and uncertainty. Uncertainty is the lack of complete certainty, or the existence of more than one possibility. Risk is the effect of uncertainty on objectives. For example, in the SBPSC, the performance of the water injection is an uncertainty, and an early water breakthrough is a risk. Petrobras’ plans aim to mitigate the main risks by treating the relevant uncertainties. The plans analyze the best strategy (treatment) for each uncertainty: information and/or flexibility and/or robustness. Table 1 is a hypothetical example of one of these plans.

Timing of Data Acquisition and Flexibility

Information is valuable only if it is available before the key decisions of the project are made. However, depending on the complexity of the information, its acquisition and application to the models may take years, and the operator may decide that it is not worth the wait (because of the loss of NPV or strategic reasons) to implement the project. Companies developing fast-track projects may opt not to wait for information to be delivered and included in the models, instead investing in flexibility.

In the SBPSC, formation water downhole samples were collected and analyzed; in some cases, a risk for calcium carbonate scaling was identified. Its real risk is dependent on the drawdown to be applied to producer wells, which depends on the productivity index of each future well. Therefore, the effective occurrence of scaling is unknown. The first SBPSC projects are investing in flexibility—smart completions with umbilicals and feed-through packers that allow injection of scale inhibitors in front of the perforations directly from the FPSO. Hydrogen sulfide scavengers, pour point depressors, and wax and asphaltene inhibitors may also be injected below the packer.

Gas handling is also being developed with allowance for flexibility. Depending on WAG performance, the efficiency of hydrocarbon miscible gas and CO2 injection, and the gas market, the topsides are being prepared to export, import, or reinject part or all of the produced gas.

Moczydlower et al. emphasize the importance of timing in maintaining the ability to exercise flexibility. While full flexibility may be planned at the start of the project deployment, availability of the flexibility may decrease with time as the implementation of the project moves forward. For instance, if the first development well reveals unexpected information, there may be adequate time to adapt the subsea layout (provided it has been designed with flexibility). However, if the information is revealed in one of the last wells when most of the flowlines, service lines, and wellheads are already in place, the remaining flexibility will be lower.

For Further Reading

ISOPE I-12-662 Treatment of Uncertainties, Risks and Opportunities in Cost and Schedule Estimates in the Early Phases of Offshore Projects by M. Gu, University of Stavanger/Aker Solutions, and O.T. Gudmestad, University of Stavanger.

SPE 152860 Development of the Brazilian Pre-Salt Fields—When to Pay for Information and When to Pay for Flexibility by B. Moczydlower, M.C. Salomão, and C.C.M. Branco et al., Petrobras.

SPE 153176 Uncertainty History Matching and Forecasting, a Field Case Application by G.G. Becerra, A.P. Modenesi, E.F.A. Lisboa, Petrobras.