The mechanical specific energy (MSE) model is used widely in the drilling industry. However, its derivation and use have recently been questioned in a series of technical papers. This paper will independently develop the theory of the MSE, leading to an improved understanding and an appraisal of the conclusions in those papers.

This paper develops the theory underlying the MSE from fundamentals and explains its applications and constraints. The theoretical development uses the concept of instantaneous mechanical power, which it transitions to drilling energy and then to drilling energy per a specific volume of rock, the MSE. The development pays particular attention to physical units. Of special interest is the relationship of the MSE to rock parameters and its use in defining mechanical efficiency, and limits, of the drill bit.

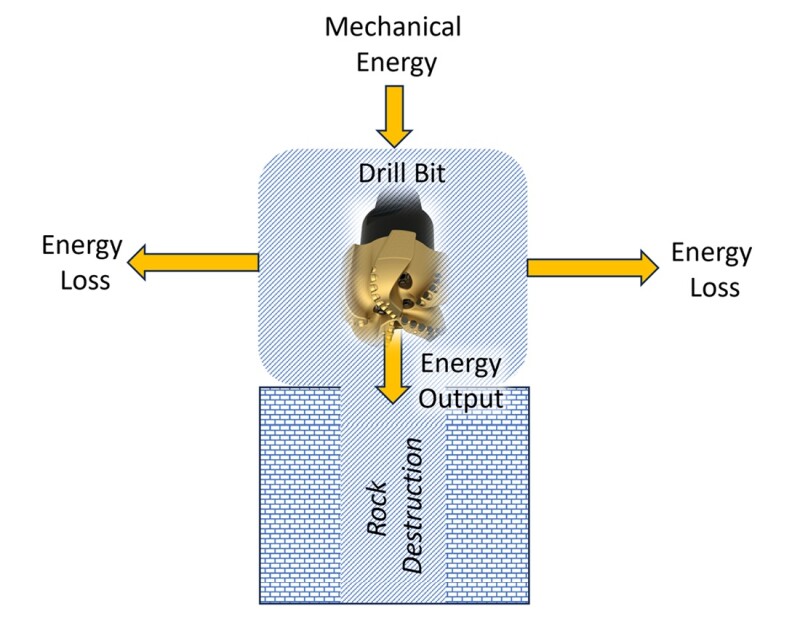

The MSE is a valid method for describing the amount of energy delivered by the drilling system to the drill bit to destroy rock. It is calculated as specific to a certain volume of rock, which in physics relates to the strain energy density (SED) of the formation. That is, the concentration of mechanical energy required to catastrophically fail (destroy) a volume of rock.

Comparison between the MSE and the SED of the formation describes the mechanical efficiency of the drill bit in converting input mechanical energy to output mechanical energy. Hydraulic energy applied at the drilling workface can both improve (e.g., clean and kerf) or impede (e.g., increase pressure overbalance) energy transfer at the workface. It is, therefore, considered separately.

Current oilfield measurement capabilities and theoretical misunderstandings introduce simplifications and errors in the MSE. It is important to understand this when using MSE. This paper examines the claims made against MSE and describes why several are incorrect. A holistic approach to drilling process management—essentially an operational approach—has merit, and understanding of MSE is important in such approaches.

This paper details the theoretical development of the MSE from a concept of instantaneous drilling power. This places the MSE on a firm theoretical basis and leads to an understanding of its limitations and valid application. The relationship of the MSE to the energy density of the formation shows that the MSE should not be compared with the compressive strength of the formation, which leads to an improved understanding of drill-bit mechanical efficiency.

This abstract is taken from paper SPE 223707 by John D. Macpherson, Baker Hughes. The paper has been peer reviewed and is available as Open Access in SPE Journal on OnePetro.