drill bits

-

This paper presents a study of trapped-torque incidents during drillpipe connection, highlighting contributing factors and root causes and proposing prevention and mitigation measures for these transient events.

-

In this study, a method was developed to analyze the effects of drilling through transitions on bit-cutting structures and construct an ideal drilling strategy using a detailed drilling model.

-

This paper describes a machine-learning approach to accurately flag abnormal pressure losses and identify their root causes.

-

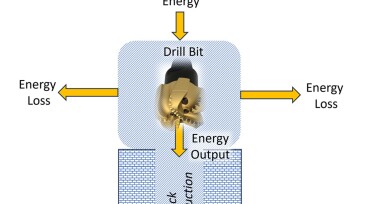

Developing the theory of mechanical specific energy from the perspective of instantaneous drilling power rather than the compressive strength of the formation leads to an improved understanding of drill-bit mechanical efficiency.

-

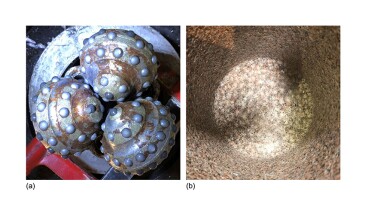

The company’s new Retina imaging system creates high-resolution borehole images at the drill bit.

-

SponsoredAltitude Energy Partners optimized drilling efficiency by minimizing dysfunctions and protecting downhole components. Their directional drilling team ensured consistent curves and laterals through precise BHA design, modeling, and trajectory control—reducing nonproductive time and drilling costs, and achieving a 100% improvement in efficiency by pad completion.

-

This paper evaluates the effect of rapid cooling on the rock-cutting process and incorporates this effect as a component of drilling-performance optimization.

-

From optimizing drilling performance to enhancing worker safety, computer vision can change how the industry works.

-

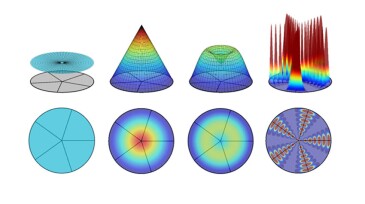

This paper analyzes the interaction of high-frequency torsional oscillations (HFTO) with lateral vibrations based on a model that accounts for the superimposed movement of whirl and HFTO at the bit.

-

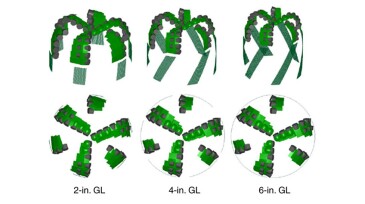

This paper describes a collaborative project to analyze affected wells, identify commonalities, and optimize bit design and drilling parameters to mitigate the effects of borehole spiraling.

Page 1 of 3