As a directional drilling service company that has developed new approaches, a major geothermal operator in Utah utilized Altitude Energy Partners (AEP) for a drilling campaign which presented some unique challenges.

Case Study: Optimized Drilling Campaign for Major Geothermal Operator in Utah

The project involved the development of a new enhanced geothermal system (EGS) using unconventional drilling techniques. The primary goal was to successfully drill the curve and lateral through a granitic formation to enable effective heat production through fractured injector and producer wells.

However, AEP’s team encountered challenges due to limited field data which required careful planning and modeling of the bottomhole assembly (BHA) and bit design to mitigate risk. Budget constraints added pressure to assess the long-term sustainability and financial feasibility of the project.

In the beginning of AEP’s service cycle, marked by initial operator meetings, a key aim is always to manage expectations and craft initial plans—and to establish effective communication protocols.

Drilling Optimization

To address the challenges of this geothermal drilling campaign, AEP implemented an iterative drilling optimization process using our Service Execution Cycle to plan, execute, analyze, and continuously improve the project.

The planning for each project was absolutely critical. That meant utilizing previous experience in drilling deviated geothermal granite wells and tapping into public Utah FORGE offset data. It also meant collaborating with other service providers for bit/BHA design, fluids, drilling parameters, and operations to create a wellbore construction solution that minimized risks during the initial deployment.

According to Armin Federico, AEP’s operations engineer, one of the particularly challenging problems resolved by AEP was the mobilizing of fit-for-purpose technology, motors, and measuring-while-drilling (MWD) systems for deployments in both conventional temperature environments and high-temperature, harsh environments. Historical data from experience in other high-temperature basins allowed for operational standard operating procedures (SOPs) to be implemented to minimize bit/BHA failure risk.

The BHAs were designed to achieve objectives specifically for the intended hole section and were tailored in both slick and stabilized configurations.

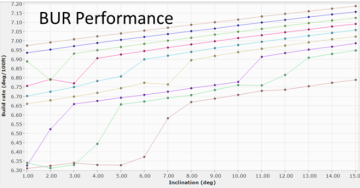

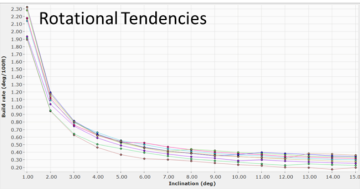

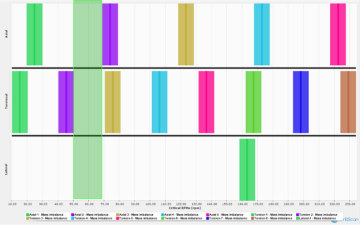

Advanced modeling performed on these BHA designs aided in determining not only steering and neutral tendencies but also provided operational parameter guidance that would directly impact the life and longevity of the drilling system as a whole.

Collection of Real-World Data

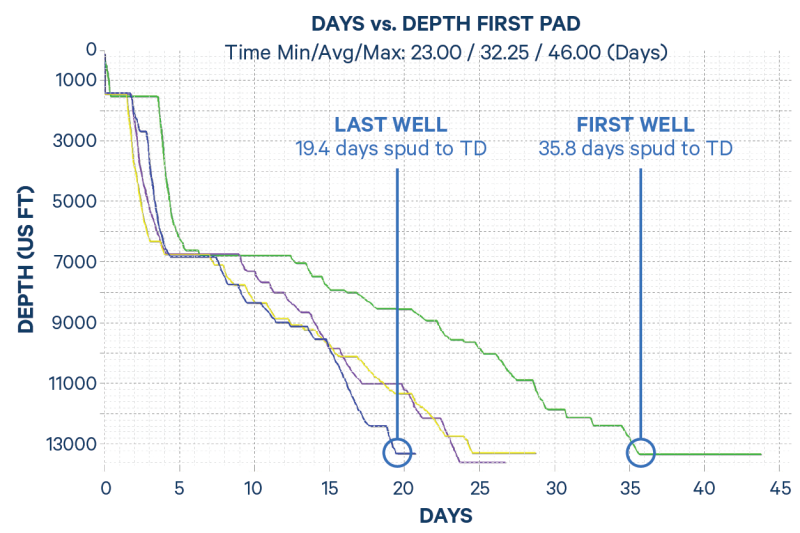

With that part done, AEP went forward to spud the first well to determine the geology and collect real-world data to compare against the computer modeling. From there, the aim was to further iterate by optimizing BHA design and drilling parameters with the objective of boosting performance and minimizing the damaging effects of drilling dysfunction. The AEP team analyzed BHAs as sections were completed to make any timely changes which were needed.

Results from early BHAs included adjusting stabilizer diameter, location, and types to maintain verticality with rotation, or create neutral lateral BHAs designed to minimize sliding and reduce vibrations. This, coupled with changes in bit and fluids, optimized the various drilling sections. Curve BHAs were modeled and optimized for steering performance in the granitic formations, allowing for reduction in motor bends and reducing stress loads.

Post-run teardown analysis would reveal the wear seen on driveline components and power sections prompting further iterative changes which included application of materials that combat highly abrasive environments.

Focus on Continuous Improvement

The entire project was focused on a routine that emphasized continuous improvement—constant communication, rigorous planning/modeling, heavy focus on execution, and constant data analysis.

According to Federico, “Throughout the operation, AEP closely monitored and optimized drilling parameters, successfully reducing drilling dysfunctions and safeguarding downhole components. AEP’s directional drillers ensured precise execution by maintaining a consistent curve and lateral through accurate BHA design and careful management of drilling parameters, while closely monitoring the wellbore trajectory. By analyzing run hours, drilling practices, and equipment wear, our drilling team was able to refine the drilling program, significantly reducing nonproductive time and lowering overall drilling costs.”

AEP applied their unconventional experience to create an EGS. Well-to-Well performance increased whenever informed decisions were based on experience and on data-based modeling with iterative execution on three multiwell pads. One focus was to optimize bit/BHA life and performance while drilling with step tests; parameter management; and drilling procedures. Federico points out that “increased performance was seen where we took time out to fully utilize the experience of our growing drilling team and when we conducted regular discussions about improving the outcome of our operations.”

In the end, the customer concluded that the results were remarkable, with the first pad alone saving 16 days. By completion of the final pad, the project demonstrated a 100% improvement in efficiency compared to the first horizontal drilled.

Pioneering Innovation: AEP’s Role in Advancing US Geothermal Projects

AEP has also been a partner for another major US geothermal project. In each project, AEP developed vastly different designs to achieve the same objectives: ESGs.

The first project, an 18,000-ft wellbore, was drilled in New Mexico through deep-underground, hard-granite rock to reach previously untapped geothermal energy. A sidetrack wellbore was created to prove that a heat- absorbing network of wellbores could be created to cycle fluid, to power a turbine generator.

Eavor Corporation’s well still stands as the deepest hole ever drilled in New Mexico. It successfully demonstrated that AEP’s new technology can crack open access to vast subsurface hot-rock formations that offer massive amounts of clean, renewable energy.

Federico said, “Operational challenges have been resolved in that now enable AEP to work with their vendors to provide fit-for-purpose geothermal drilling solutions which can be deployed with a high confidence of success.”

He added that it was “operational experience at AEP that made it possible to take informed decisions that optimize bit life and performance with step tests parameter management and with drilling procedures. It was also constant communications about KPIs and about section milestones—both of which further increased performance of the program.”

Going forward, AEP is looking at partners in both the US and Canada. The Alberta Drilling Accelerator provided the map below which helps to identify potential geothermal sites of interest for projects to expand technical knowledge.