Dynamic phenomena while drilling such as borehole spiraling or corkscrewing can create a physical imprint on the borehole surface, which masks fine features of imaging. During a drilling campaign in a carbonate reservoir using logging-while-drilling (LWD) technology, corkscrewing affected ultrahigh-resolution borehole image quality severely. The complete paper presents the methodology and results of the bit-design test to mitigate the presence of borehole spiraling, resulting in a significantly improved ultrahigh-resolution borehole image.

Introduction

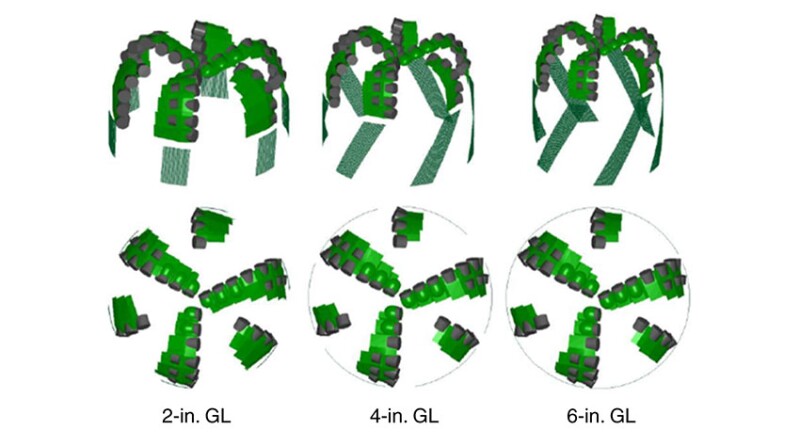

A recent drilling campaign in an offshore carbonate reservoir in horizontal wellbores required the use of resistivity-based LWD ultrahigh-resolution images (UHRI) with rotary steerable systems (RSS) to evaluate the presence of natural fractures. During LWD logging of the targeted carbonate reservoirs using water-based mud, borehole artifacts were observed as spirals around the borehole.