drill bits

-

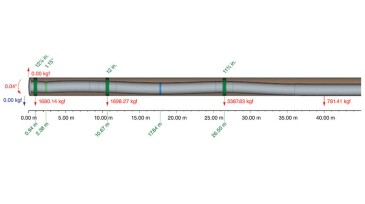

In this paper, bottomhole-assembly lateral behavior is analyzed using different types of computations, including static, dynamic, frequency-based, and time-based.

-

SponsoredTesting new drilling technology in a controlled and monitored environment before it is launched to its full extent in the field—that is what the Rijswijk Center for Sustainable Geo-energy is all about.

-

Derived from the principles of radial jet drilling, a new technology called micro-turbine drilling is developed to allow for drilling of micro-sidetracks from cased boreholes in very hard reservoir rock.

-

This paper describes an 18-month intensive continuous improvement process between an operator, a rig contractor, and bottomhole-assembly (BHA) service providers aimed at reducing BHAs per well in two Oklahoma rigs.

-

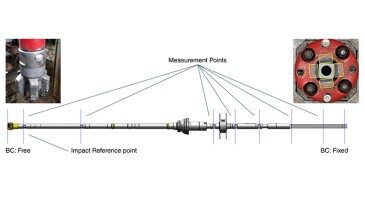

This paper discusses a full-scale drilling test rig that allows comprehensive study of the influences of bit characteristics on high-frequency torsional oscillations (HFTO) for the first time.

-

The US-based drilling contractor is buying the drilling technology company just three weeks after announcing a merger with NexTier Oilfield Solutions.

-

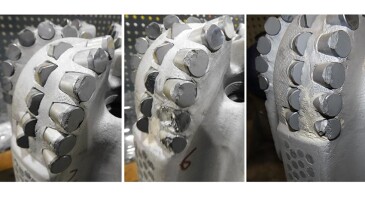

Results from more than 50,000 runs where shaped cutters resolved drilling issues demonstrate that, by matching the combination of cutters to the formation and the downhole conditions, it is possible to improve ROP, extend bit life, and drill longer runs for more cost-efficient operations.

-

This paper highlights the potential of machine learning to be used as a tool in assisting the drilling engineer in bit selection through data insights previously overlooked.

-

Founded in 2008, GA Drilling is developing plasma-based tools to achieve drilling speeds that are about three times faster than what conventional bit technology has historically achieved.

-

The complete paper presents a methodology designed for optimally matching drill bits, mud motors, and bottomhole-assembly components for reduced failure risks and improved drilling performance.