Flowback water from unconventional reservoirs in Argentina and other shale plays worldwide contains a microbiome rich in the bacterial genus Halanaerobium. This microorganism is native to these reservoirs and thrives in surface facilities, where it contributes to microbiologically influenced corrosion (MIC), primarily through thiosulfate reduction, organic acid production, and biofilm formation. Consequently, Halanaerobium is the key target genus to control in the surface facilities of Vaca Muerta’s unconventional production.

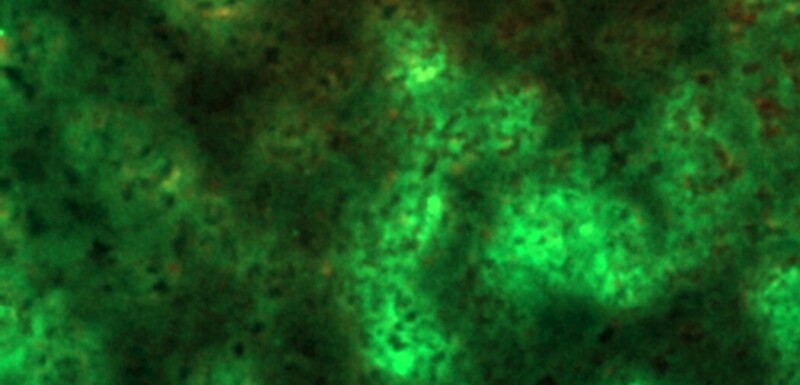

This study presents a tailored integral solution implemented at laboratory and field conditions. Both planktonic and sessile in-vitro cultures of the target genus were developed in the laboratory, and effective biocidal formulations were selected through adenosine triphosphate (ATP) kill tests, fluorescence, and confocal microscopy. In the field, treatment applications were designed based on MIC risk assessments and integrated with advanced and comprehensive monitoring techniques, including ATP counts, target-specific quantitative polymerase chain reaction counts, metagenomic analysis for complete microbial diversity, spectroscopic characterization of corrosion products, and corrosion rate monitoring using carbon steel coupons.

The application of this solution in an unconventional crude-oil treatment plant in Argentina demonstrated its effectiveness. The defined key performance indicators were successfully achieved—a reduction in total microorganism counts, a decrease in corrosion rate, and the elimination of the target genus in liquid streams—underscoring the treatment’s effectiveness at a competitive application cost. It is worth mentioning the treatment also induced changes in the microbiome, suggesting that ongoing customization of mitigation tools may be beneficial.

This abstract is taken from paper SPE 228313 by M. Pagliaricci, G. Rojas, F.L. Massello, and J. Dos Santos, YPF Tecnologia; E. Bortoli and S. Navarrete, YPF Química, Ciudad Autónoma de Buenos Aires; W. Morris, YPF Tecnologia; W. Vargas, YPF, Ciudad Autónoma de Buenos Aires; and I. Vega, YPF Tecnologia. The paper has been peer reviewed and is available as Open Access in SPE Journal on OnePetro.