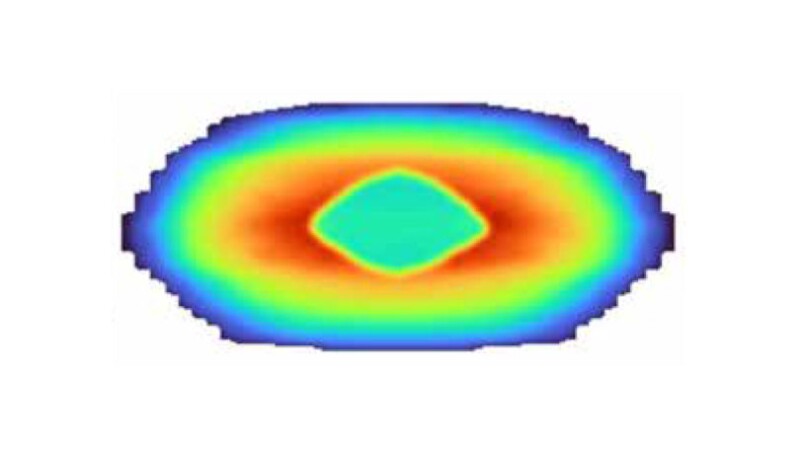

With the aid of a multiphysics simulator, the authors recently presented a novel use of a degradable fluid-loss additive (DFLA) as a fracture geometry additive to reduce the pad volume while achieving the same geometry. In this complete paper, the authors extend advanced slurry flow modeling with production simulation to propose the optimal design strategy for fracturing, which may challenge current treatment-design conventions. A novel work flow was developed, with four coupled working blocks of laboratory, slurry flow modeling, production analysis, and machine learning. The new digital framework proposes solutions for the limitations of current methodology.

Introduction

Across different generations, multiple fluid additives have been introduced to target specific treatment objectives; one of these that has been available for years, but that has been underused, is fluid-loss additive (FLA). Theoretical and field bases have been presented for its use in the following applications:

- Conventional prolific reservoirs to mitigate high fluid loss and create sufficient fracture geometry

- Tight gas formations with high tectonic influence to mitigate poroelastic effects and fissure-dependent enhanced leakoff

- Unconventional reservoirs to avoid repression during production

- Openhole wells to control multiple fracture initiation

- Multipad wells to avoid interwell communications and fracture hits

- Fracturing treatments aimed at optimizing and reducing crosslinked pad volume

Despite these benefits, the primary issue of using an FLA is its potential to damage fracture conductivity and the reservoir.