As an operator of 30,000 miles of natural-gas pipeline systems, including gathering and boosting (G&B) facilities, Williams is taking steps to further mitigate greenhouse gas (GHG) associated with its operations (see sidebar).

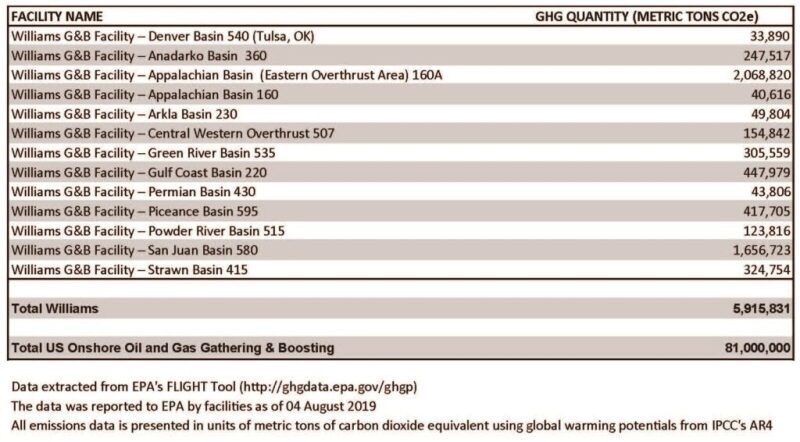

The US Environmental Protection Agency (EPA) compiled data for GHG quantities as metric tons of CO2 equivalent (CO2e) based on self-reported data from the facilities as of 4 August 2019. Among the results are 13 of Williams’ onshore gathering and boosting facilities (Table 1).

While this is a snapshot of one segment of a company’s operations, it illustrates the importance of mitigation throughout the natural-gas value chain.

Leak detection and equipment upgrades play a significant role in the mitigation of methane and carbon dioxide emissions. Various equipment components involved in G&B systems such as compressors, tanks, dehydrators, acid-gas-removal units, separators, and yard piping are recognized emitters.

An EPA report issued in April, Inventory of US Greenhouse Gas Emissions and Sinks 1990–2018, identified the sources of GHG emissions from G&B systems as the G&B stations and gathering pipelines.

G&B stations receive natural gas from production sites and transfer it via gathering pipelines to transmission pipelines or processing facilities. Boosting processes include compression, dehydration, and transport of gas to a processing facility or pipeline.

The EPA identified five major segments of the natural-gas system: exploration, production (including G&B), processing, transmission and storage, and distribution. It categorized “production” as beginning at the withdrawing of raw gas at the wellsite. Emissions arise from the wells themselves and from wellsite equipment and activities such as pneumatic controllers, tanks and separators, and liquids unloading. The EPA included G&B emission sources within the production sector.

In 2018, emissions from production (including G&B) accounted for 58% of methane emissions and 27% of carbon dioxide emissions from natural-gas systems.

Within the production data, G&B sources took the top position for the most emissions in several categories.

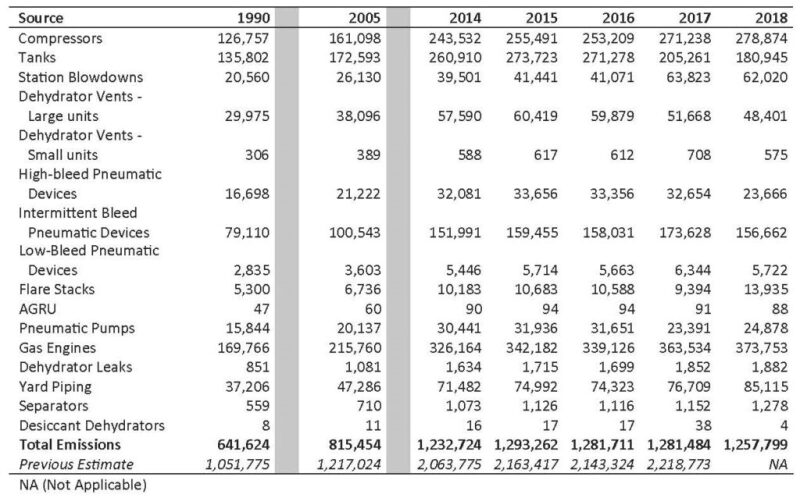

Methane. Primarily because of increases in emissions from pneumatic controllers (caused by an increase in the number of controllers, particularly in the number of intermittent-bleed controllers) and increases in emissions from compressor exhaust slip in G&B, methane emissions from production increased by 41% from 1990 to 2018. The largest sources are compressor exhaust slip, compressor venting and leaks, and pneumatic controllers. From 2017 to 2018, methane emissions decreased 2% because of decreases in the number of high-bleed and intermittent-bleed controllers. Methane emissions were highest in 2008–2013 (Table 2).

Carbon. Flaring emissions account for most of the carbon emissions from production, with the highest emissions coming from flare stacks at gathering stations, miscellaneous onshore production flaring, and tank flaring.

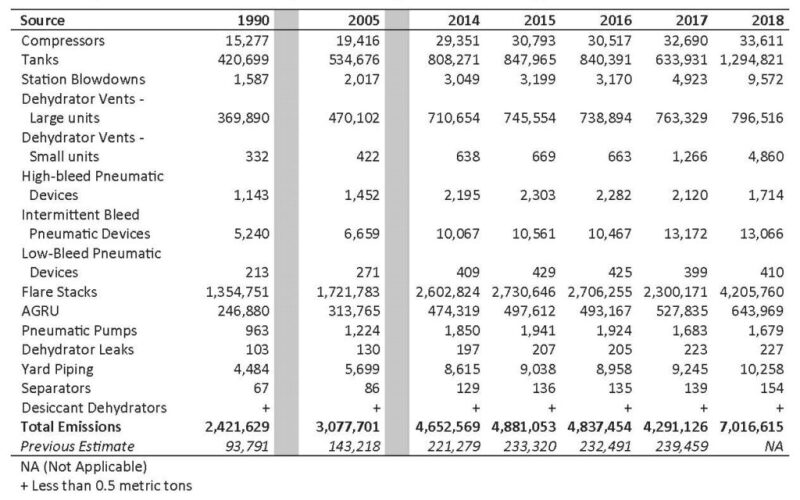

Carbon dioxide. Emissions from production increased approximately by a factor of three from 1990 to 2018, because of increases in emissions at flare stacks in G&B and miscellaneous onshore production flaring, and increased 47% from 2017 to 2018, primarily because of increases in emissions from flare stacks in G&B and flaring at tanks. Carbon dioxide emissions were highest in 2018 (Table 3).

Nitrous oxide. Emissions increased 35% from 1990 to 2018 and increased 36% from 2017 to 2018. The increase in nitrous oxide emissions from 1990 to 2018 and from 2017 to 2018 is primarily because of the increase in emissions from flare stacks in G&B.

Read OGF’s “Who’s Minding the Methane? Federal Emissions Rules in Flux, States and Industry Take the Reins” to compare the results with those reported in the EPA’s 2016 Greenhouse Gas Reporting Program.

Williams Companies Aims for Net-Zero Carbon Emissions by 2050

Williams Companies announced a near-term goal of a 56% absolute reduction from 2005 levels in greenhouse gas emissions (GHG) by 2030, aiming for net-zero carbon emissions by 2050. The company owns and operates more than 30,000 miles of pipelines and handles approximately 30% of the natural gas in the US.

Based in Tulsa, Oklahoma, the company plans to reduce methane emissions through leak detection and repair, evaluating equipment upgrades on a site-specific basis, and by scaling renewables to reach its 2030 target.

In June 2019, Williams joined Our Nation’s Energy Future Coalition (One Future), a natural-gas-industry-led organization dedicated to voluntarily achieving reductions in methane emissions across the natural-gas value chain.

It said then that, since 2012, it had reduced methane emissions from its gas processing plants and transmission compression stations by more than 53%, even though throughput at the facilities had increased by 21%. In 2018, its pipeline blowdown GHG emissions were reduced by 83.5% by using pressure-reduction via recompression to lower gas-line pressure before pipeline maintenance work.

Landfill and Dairy Farm Biogas

Williams currently delivers renewable natural gas (RNG) in partnership with energy companies in Idaho, Ohio, Washington, and Texas to transport methane emissions captured from landfills or dairy farms. Its Northwest Pipeline is interconnected with four RNG facilities, of which two were brought on line in the past 7 months.

Landfill-produced methane, a byproduct of the waste-decomposition process, is a renewable fuel because methane is captured as biogas instead of being released directly into the atmosphere. Williams analyzes the biogas to ensure it is pipeline quality and that it can be safely commingled with conventionally produced gas.

Last April, Brightmark Energy, a San Francisco-based waste and energy development company, launched a biogas project in Yakima County, Washington, to convert 150,000 gallons per day of dairy waste from up to 7,000 cows into 160,000 MMBtu of RNG—the equivalent of 1.4 million gallons of gasoline—and other products each year. Collaborating as Augean Renewable Natural Gas, Brightmark, Promus Energy, and DeRuyter Dairies developed the project.

Yakima County and Augean built new pipeline infrastructure to collect biogas from DeRuyter’s anaerobic digester fueled by cow manure. The raw biogas is cleaned, upgraded, and compressed into pipeline-quality RNG, which is transported through the new pipeline system and injected into the nearby Williams Northwest Pipeline for sale as vehicle fuel. Williams estimated the project will offset approximately 50,000 metric tons of GHG emissions per year, the equivalent of taking nearly 11,000 cars off the road each year.

Solar Installations To Power Company Facilities

Williams recently announced a $400-million solar initiative across nine states to power some of its gathering and processing sites. The installations will be located on company-owned land that is adjacent to existing facilities. Initial sites have been identified in Alabama, Colorado, Georgia, Louisiana, New Jersey, North Carolina, Ohio, Pennsylvania, and Virginia that are expected to be placed into service beginning in late 2021.

In total, Williams’ facilities draw more than 400 MW of electricity. The company anticipates that agreements with local utilities will allow excess solar power not used by its facilities to be sold back into the grid.

The company also plans to prepare for future breakthrough technologies in carbon capture, synthetic gas, and hydrogen as a fuel source to achieve net-zero emissions by 2050.

The company’s 2019 sustainability report, released on 3 August 2020, is available here.