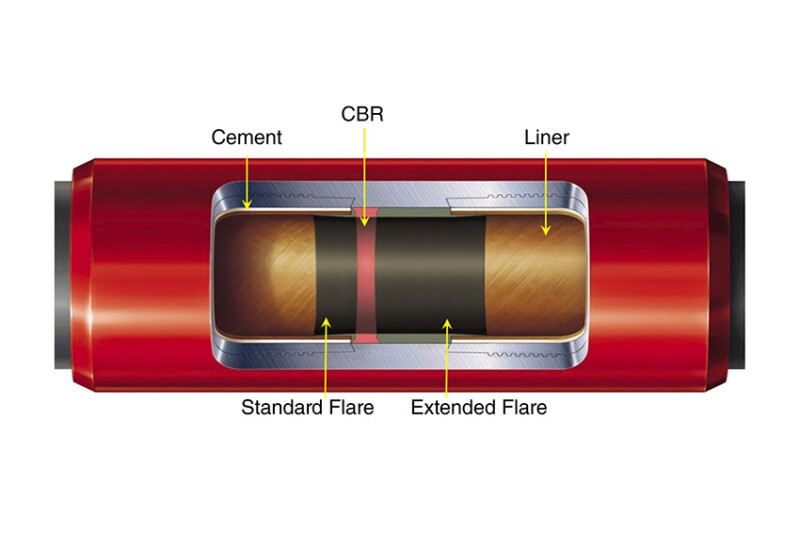

Tubular glass-reinforced-epoxy (GRE) lining technology has been applied globally since the 1960s in eliminating downhole tubular corrosion. Compared with conventional carbon steel, which can experience frequent failure, GRE-lined carbon steel provides long-lasting protection, resulting in huge savings in life-cycle cost. The operator implemented this technology for a successful trial of water-disposal wells. In the complete paper, the authors share the data from caliper logs run into, and the inspection of tubing pulled from, these disposal wells after 4 years in service.

Tubular Corrosion in Operator Assets

A growing emphasis on water disposal was inevitable because so much water was being produced with increased water cut and production.

×

Continue Reading with SPE Membership

SPE Members: Please sign in at the top of the page for access to this member-exclusive content. If you are not a member and you find JPT content valuable, we encourage you to become a part of the SPE member community to gain full access.