Background

Oil and gas production from the Middle East region has been steadily increasing during the past decade to meet global consumption demands and to maintain the Middle East countries' market share. As reported in BP Statistical Review of World Energy 2021, the Middle East accounted for 31% of global oil production and 17.7% of natural gas production. In terms of reserves, on the other hand, it hosts 48% of proved oil reserves and 40% of proved gas reserves.

This clearly shows the bias toward gas production. Gas can be considered relatively underdeveloped as only 17.7% of global gas is produced by Middle East countries, which illustrates the significant potential of currently underutilized gas production when 40% of gas reserves reside in the Middle East.

This rather big gap between Middle Eastern gas reserves and gas production is largely due to the geography separating the Middle East from the main gas markets in Europe and Asia until LNG technology matured to overcome this challenge and enable the transfer of LNG across the continents. This opened new markets for Middle East gas and helped to stimulate gas development projects in the region.

The abundance of prolific good-quality oil reserves kept Middle East NOCs and IOCs busy producing economical oil. Developing gas reserves, on the other hand, required more advanced technologies and higher-rated equipment to access unconventional and tight HP/HT reservoir environments. Hence, the economic feasibility of gas development projects was often downgraded when compared to the more conventional oilfield developments.

Middle East Unconventional and Tight HP/HT Reservoirs

Unconventional and HP/HT tight-gas reservoirs are becoming very popular within the region as gas prices and both local and global demand continue to increase. As a result of the increasing interest in gas production within the Middle East, it increased by 37.5% during the past decade, from 520 Bcm in 2011 to 714.9 Bcm in 2021, while global gas production increased only by 23.9% within the same period.

Consequently, Middle East gas production market share increased globally from 16 to 17.7% during the same 10-year period, and a significant part of the gas production increments are contributed from tight and unconventional reservoirs.

The Saudi development of a 200 Tcf unconventional gas field, named Jafurah Basin, for an estimated budget of USD 100 billion and UAE's development of 80 Tcf of the Jebel Ali gas field are only a few examples, among many, in the Middle East region.

Additionally, several unconventional oil and gas discoveries were announced such as Al-Reesh field northwest of Dhahran, the Al-Ajramiah field and the Abraq Al-Talul oil and gas field in the Northern Borders in the Kingdom of Saudi Arabia (KSA), and the Hadbat Al-Harjah gas field in the Al-Jawf area of KSA.

Upstream Oilfield Service Companies Adapting to the New Industry Trend in the Middle East

To keep up with the emerging focus on the development of unconventional and tight reservoirs, upstream oilfield service companies in the region had to adapt very quickly by adopting new technologies. In many cases, they had to develop tailored fit solutions that are most applicable for the challenges faced locally in developing these fields.

For example, when it comes to TAQA, the company grasped the importance of having in-house technologies and engineering capabilities that will enable the business to provide the optimum solutions to its customers in developing unconventional and tight-gas reservoirs. Hence, the company dedicated significant resources from different business lines to develop new or upgraded existing technologies, new recipes, and new methodologies that will allow the customers in the Middle East region to optimally develop unconventional and tight-gas reservoirs.

The next section showcases a few examples of TAQA-developed technologies that are applicable and tailored to fit unconventional and tight-gas reservoirs.

Cementing Technologies and Recipes

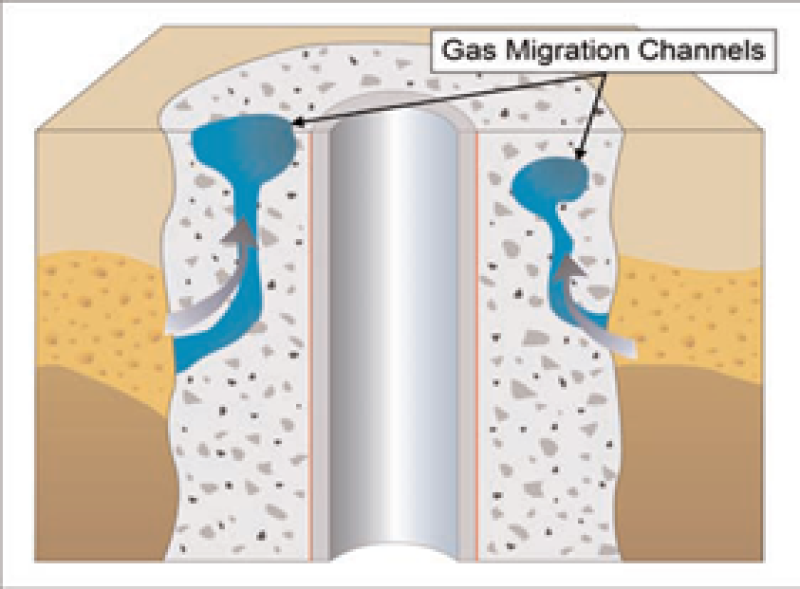

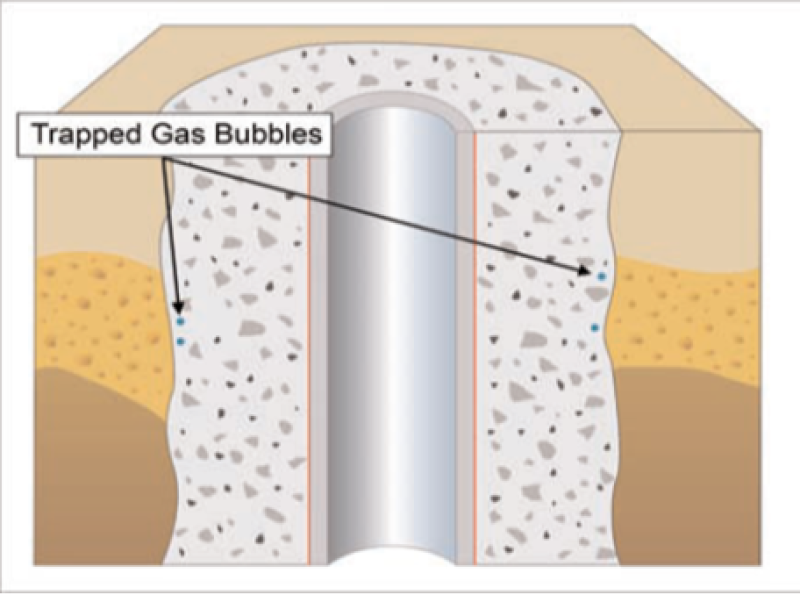

GCA-2 Gas Tight System—In-house developed novel fluid migration control slurry system that is highly effective in mitigating the occurrences of sustained casing pressure, which is a common problem in gas high-pressure wells. It is also both reliable and cost-effective when compared to a conventional latex-based slurry system, as illustrated in the figures below. This slurry is successfully deployed for the primary cement jobs in several wells.

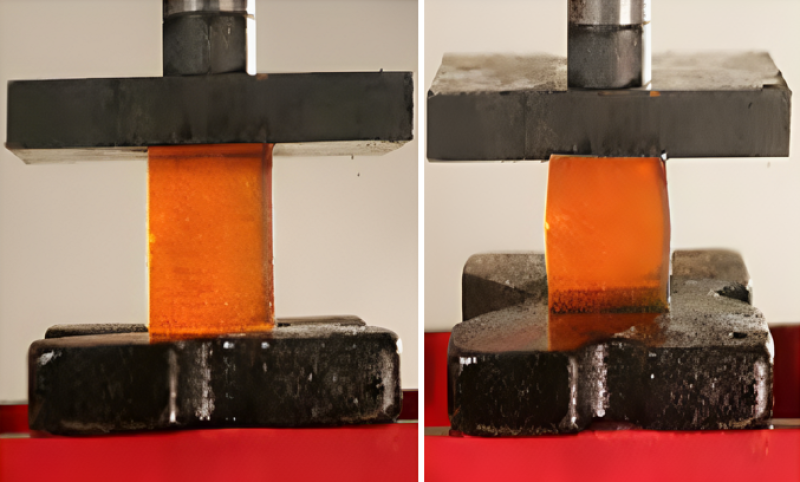

Resin Cement System—An in-house designed resin-cement system that maintains adequate compressive strength and flexibility. It also mitigates the risk of cement sheath failure throughout the life of the well. Therefore, it provides a long-term well integrity solution for any well exposed to a high-pressure and high-temperature environment. As a result, resin cement is very applicable in tight-gas reservoirs. The figures below illustrate the increased resin strength and flexibility, even with high forces applied.

Fracturing and Stimulation Technologies and Recipes

Nexus Acid Fluid System—A recent frac fluid developed by TAQA, which is highly applicable in unconventional reservoirs. It is a single-phase acid system which controls the dissolution rate of the carbonate and a suspension aid to prevent fallout of the reaction products. Nexus is particularly effective in carbonate reservoirs at high temperatures and long intervals of fracturing where placement can be challenging with acid only. As Nexus fluid does not impact the viscosity of the system, there are no adverse effects on pumping pressure. Additionally, the single-phase nature of the additive means that it can be added on the fly or batch-mixed. Nexus is compatible with commonly used additives including corrosion inhibitors and has the added benefit of scavenging H₂S. Nexus Acid Enhancer is effective at exceptionally low concentrations, making it operationally easy and cost-effective.

CO2 Fracturing—In addition to TAQA’s vast capabilities in delivering complex fracturing solutions including tight-gas and multistage hydraulic fracturing operations, TAQA introduced its own high-tier foamed CO2 fracturing recipes. The primary purpose of pumping foamed CO2 fluids during fracturing operations is to aid in post-fracturing flowback, especially in tight and/or low-pressure formations, where the reservoir is not supporting sufficient energy to flow back the fracturing fluids. This technology is available and fit-for-purpose in tight and unconventional reservoir development.

High-Temperature Fracturing Fluid System AQUAjel—It improves production gain from fracturing treatments by utilizing low-residue double derivatized carboxy methyl hydroxypropyl guar polymer (CMHPG). The fluid has superior proppant transport capabilities, and the guar refinement results in improved thermal stability and better rheology at elevated temperatures. The fluid has excellent cleanup properties and leaves minimal polymer residue after breaking, resulting in better effective proppant pack conductivity and leaving much larger pore space open for hydrocarbon flow than conventional fracturing fluids. It’s designed for high-temperature fracturing applications and is suitable for wells with a bottomhole temperature of up to 375°F. The versatile crosslinking delay mechanism of the fluid allows for strong control over the fluid’s crosslinking timing which reduces fluid’s tubing friction and minimizes exposure to high- shear environments and their possible negative effect on rheology. The superior leakoff properties of the fluid allow for better placement results and the customizable break profile permits effective break times optimization which enhances the post-frac clean-up.

References

BP Statistical Review of World Energy 2021

BP Statistical Review of World Energy 2022

SPE/IADC 202103 Application of Resin-Cement Blend To Prevent Pressure Buildup in Casing-to-Casing Annulus CCA: A Novel Approach To Improve Well Integrity by Wajid Ali and Freddy Jose Mata, TAQA Sanjel; Ahmed Atef Hashmi and Abdullah Saleh Al-Yami, Saudi Aramco.

SPE 213453 Novel Carbon Dioxide (CO2) Foamed Fracturing Fluid, an Innovative Technology To Minimize Carbon Footprint by Mathew Samuel, OPT Chemical Technologies; Ziad Al-Jalal, Nurlan Nurlybayev, and Mohammad Farouk, TAQA; Zhijun Xiao, Cheng Kang Kang, and Li Huanming, OPT Chemical Technologies.

SPE 213494 Addressing Hydraulic Fracturing Performance Challenges in HPHT Well With New Fluid System and Comprehensive Fracturing Study Utilizing Full 3D Simulator by Nurlan Nurlybayev and Ziad Al-Jalal, TAQA; Mathew Samuel, OPT Chemical Technologies; Mohammad Farouk, Mustafa Ghazwi, Ali Yaseen, and Raja Jalil Muhammad, TAQA.