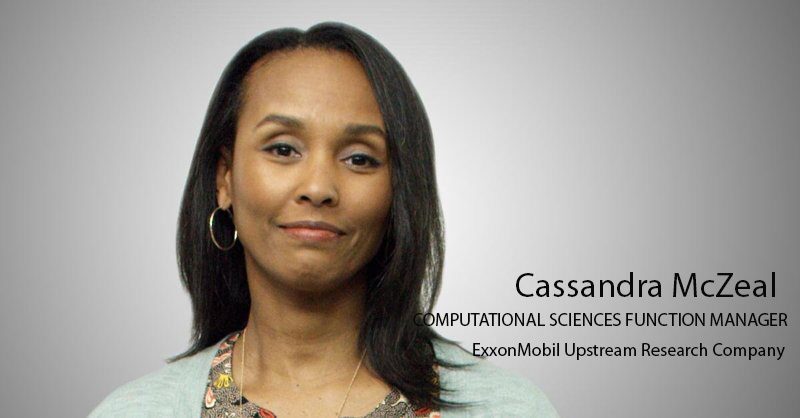

Optimization and analytics are “playing a vital role in what we do every day,” ExxonMobil’s Cassandra McZeal said in a keynote address on 24 October at the Institute for Operations Research and the Management Sciences annual meeting in Houston.

McZeal, computational sciences function manager at ExxonMobil Upstream Research Company, said the corporation has developed and is using proprietary applications in the field that often are “hot off the press” and “changing on a daily basis,” with related research continuing.

Computational Science ‘Pillars’

The four “pillars” supporting the computational sciences within ExxonMobil, she said, are computational and applied mathematics, mathematical modeling and physical processes, technical software engineering, and high-performance computing.

McZeal said that data analytics is “super popular in the media right now” but that many people in the corporation’s research bodies have worked in the field 20 or 25 years.

“We are fundamentally an engineering company,” McZeal said, and it is principally the engineering and geoscience areas where optimization and analytics are used “to really improve our business.”

She presented a number of examples from the corporation’s upstream, midstream, and downstream businesses. In exploration and production, she covered several applications that include

Exploration geophysical subsurface modeling

Offshore field development

Gas-lift well production

Subsurface Modeling

In exploration, the use of full-waveform inversion methods for geophysical subsurface modeling requires major data management and presents “a really difficult” nonlinear data-fitting problem, McZeal said.

Modelers make a guess of what the seismic output of a specific, seismically surveyed prospect area would be and compare it with the actual seismic output. “We do a forward model and an adjoint model to try to match those two up,” said McZeal, who described the problem as “a super-hard fitting (of data) to a system of hyperbolic, partial-differential equations.”

In offshore field development, operators must determine the number and type of platforms or production facilities that may be needed, their locations relative to each other, and what the connections between them will be. At the same time, it is necessary to keep track of changes in the reservoir, and market fiscal terms must be applied to all production.

“So we’re looking for the most economic development plan for multiple scenarios, given our reservoirs, wells, infrastructure, our capacities, our export constraints,” she said. “This ends up being a mixed-integer nonlinear programming problem.”

Gas-Lift Wells

For wells producing with gas-lift technology, the company is using a naive Bayes algorithm method to characterize well vibrations and pressures that enable the prediction of slugging events so that gas-lift adjustments can be made to prevent them.

Data and analytics are also used to predict instability in wells with multiple lift-gas injection valves so that the valves can continue to open and close appropriately.

In another application, data are analyzed to predict when gas-lift rates will become suboptimal and begin to lose their effectiveness.