In the Danish central graben, tight chalk reservoirs have been developed successfully through drilling, completion, and stimulation of long horizontal wells. These fields, developed since the early 1970s, are operated on behalf of a joint venture, the Dansk Undergrunds Consortium (DUC). One of the most successful technologies used in these fields is the controlled-acid-jetting (CAJ) technique.

Lower Cretaceous Formation, Central Graben

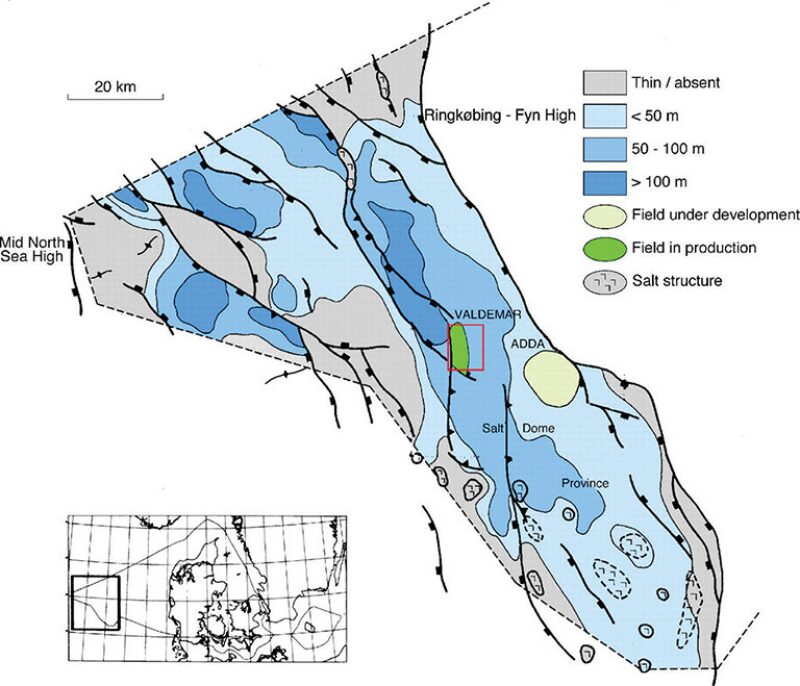

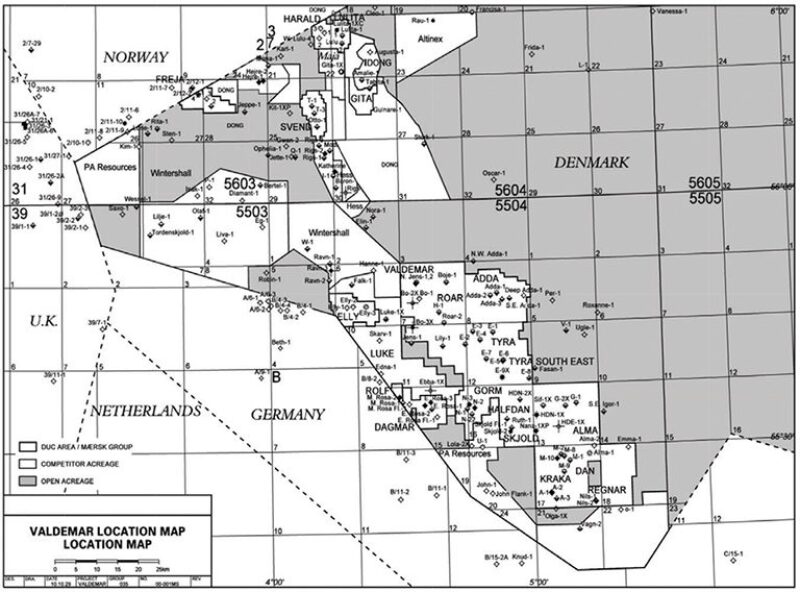

Fig. 1 shows the major producing fields of the DUC area. The Lower Cretaceous reservoir contains significant in-place oil volumes. Fig. 2 above shows the thickness map of the Tuxen and Sola Lower Cretaceous formation in the central graben. This formation historically has posed a challenge to development because of its extremely low permeability; in addition, the formation is soft, highly heterogeneous, and has significant clay content in some areas. Thicker Lower Cretaceous reservoir sections in the Valdemar field have been propped-fracture stimulated successfully. Acid stimulation is preferred for the thinner sections; however, early attempts at matrix acid stimulation were very disappointing. Recently, the need to re-enter a well for maintenance allowed three zones to be selectively restimulated with improved execution techniques and a more appropriate acid formulation. Production increase following restimulation of this first well was very encouraging, and the lessons learned were applied to a second well.

The Lower Cretaceous formation is characterized by a high content of insoluble residue (IR), consisting mainly of clay with subordinate amounts of quartz, rare pyrite, and organic material. Porosity correlations were developed from core data and by petrophysical evaluation of logs. The porosity varies considerably, but is generally remarkably high. While the primary variation in porosity was linked directly to the IR content of the facies, factors such as pore pressure and depth of burial/compaction also had an influence.

On the basis of the formation core data, the Lower Cretaceous would not be considered a good candidate for matrix acid stimulation. It is well established, however, that low-permeability reservoirs can be economically produced by long, horizontal wellbores that effectively maximize reservoir contact.

Acid Stimulation in Carbonate Formations and the Role of Wormholes

The goal of acid stimulation under matrix conditions in carbonate formations is to create highly conductive flow channels known as wormholes that bypass the damage in the formation. These flow channels establish the connection between the wellbore and hydrocarbon-bearing formation, thus allowing the hydrocarbons to flow into the wellbore at a minimum drawdown pressure. The wormholes are formed when the matrix of the porous and permeable rock is dissolved by reactive fluids such as hydrochloric acid (HCl). To obtain high negative skin, the wormholes must penetrate beyond the damage zone and create a region of ultrahigh permeability. The matrix acid treatment must be performed in such a way that deep penetrating wormholes are generated. The three important treatment parameters that should be considered are fluid volume, injection flow rate, and fluid type.

The factors affecting wormhole efficiency have been studied by numerous researchers over the past 30 years. Hundreds of laboratory tests have been performed with many types of carbonate rocks and different test-sample/-injection configurations. Several mathematical models have been proposed to predict the conditions under which effective wormholing will occur. While industry may still debate the most appropriate laboratory procedures for wormhole testing and the most appropriate method to scale the laboratory data to field conditions, it is well accepted that there is, indeed, an optimum injection rate. It is further accepted that (in addition to the treatment parameters mentioned previously) formation parameters such as mineralogy, permeability/porosity/pressure profiles along the wellbore section, reservoir-fluid properties, saturations, and bottomhole temperature will greatly influence wormhole-growth rates and hence the efficiency of matrix acid-stimulation treatments.

Before 2007, the general belief was that the Lower Cretaceous formation could not be effectively acid stimulated. It was recognized that the acid/rock reaction would need to be studied in order to optimize acid stimulation and increase the probability of economically producing the thinner sections of the Lower Cretaceous reservoirs.

Sixteen wormhole tests were conducted, evaluating five different acid blends over a range of 10 injection rates. Because the cores were not preserved, experimental deviations could not be avoided. However, in all cases except those with very low injection rates, there was clear evidence of wormhole formation. The practical implication was that the Lower Cretaceous formation is indeed responsive to acid.

CAJ Stimulation

The CAJ completion method is so named because the distribution of acid jetted onto the formation along the entire noncemented liner is controlled by the number of predrilled holes. Acid is pumped at high rates and exits the holes at high velocities, resulting in jetting of the formation. By limiting the number and size of holes, a choke effect is obtained and a significant pressure drop occurs between the inside and the outside of the liner during stimulation. A nonuniform geometric distribution of the holes is used to compensate for the frictional pressure drop along the liner section. This means that the average hole density increases toward the toe of the CAJ liner. The open annulus outside the liner, in combination with the overpressure on the inside of the liner (caused by the choking over the holes), ensures that the acid eventually reaches the bottom of the very long liner, and that the well is thus stimulated along its full length.

Unfortunately, applying the CAJ concepts to the Lower Cretaceous formation involves two significant complications. First, drilling of the formation requires the use of oil-based mud because of formation compatibility issues, maximum allowable equivalent circulating density, and drag associated with running the CAJ liner. Second, the low permeability of the formation contributes an additional significant resistance to flow, thus limiting the maximum injection rates possible during CAJ. Therefore, the CAJ process should be optimized in order to acid-stimulate and produce thinner sections of the formation effectively.

Laboratory Testing

One of the critical areas to be investigated is the frictional pressure drop across the perforations ΔPperf, which is influenced by the perforation coefficient Cp. The main objective was to study Cp through laboratory experiments. A laboratory setup for measuring the pressure drops for different types of fluids at different flow rates was constructed. To evaluate overall effects, the perforation pressure drop with each acid blend was measured and then used to calculate the fluid-specific Cp in order to clarify any changes caused by the introduction of additives.

It was a challenging task to bring the CAJ stimulation process from field scale to laboratory scale. The objective was to test five different types of fluids [seawater, slick seawater, 15% HCl, 15% gelled HCl, and 15% in-situ-crosslinked acid (ICA)] through a pipe with a single perforation. It was decided to design and construct a pipe with a perforation diameter of 3 mm. Using precalculations of the typical CAJ-stimulation flow rates and predrilled CAJ hole dimensions, it was possible to design a functional setup for the experiments. It was concluded that a 0.9144-m-long pipe (internal diameter = 6 mm) of stainless steel would be sufficient and would provide a practical approach. The pressure gauge was to be placed 15 cm from the perforation. The data show, as expected, that the perforation frictional pressure drop increases significantly with increase of rates. There are two groupings of data: the nonviscous fluids as one set and the gelled acid and ICA as the other. If the gelled acid and the ICA both contained the same amount of gelling agent, then it makes sense that the gelled and nongelled acids would behave similarly. In the performed tests, however, the gelled acid contained 0.1% gelling agent and the ICA contained 2% gelling agent.

One of the goals was to determine if friction reducer (gelling agent) affects the pressure drop across the orifice. Examination of the data indicates that the friction reducer has an effect when added to acid, but only a negligible effect when added to seawater. Of significant interest is the fact that the experimental results indicate that Cp decreases in proportion to the increase in ΔPperf. It is notable that the fluids with highest ΔPperf have the lowest values for Cp.

The oil industry has traditionally defined the perforation coefficient as a constant. CAJ-liner hole distributions are typically designed assuming a Cp value of 0.56. The laboratory testing indicated higher values of Cp than normally assumed. The difference could be caused by the fact that orifice-theory calculations are based upon straight-line flow (e.g., down a pipe with a restriction), whereas flow down and out of a CAJ liner is bidirectional. The important observation is the variation in Cp with fluid type, indicating that for proper design and evaluation of a CAJ liner, the fluid-specific Cp values need to be known.

Estimation of Zonal Coverage in CAJ Stimulations

One of the main success criteria in acid stimulation of CAJ-liner-completed wells is the realization of full zonal coverage along the liner. It is expected that initially the injected acid will be injected into the heel of the horizontal lateral. With increasing injection rates, the limited-entry CAJ-liner concept will assist in obtaining improved zonal coverage.

Evaluation of zonal coverage by use of direct measurements has not been performed. Therefore, a real-time CAJ-stimulation diagnostic tool was developed to derive the amount of zonal coverage from pressure responses during pumping and following an instantaneous shut-in. The difference between the pressure during pumping and that of the instantaneous shut-in is a measure for the total friction in the system. The total friction can be divided into pipe friction and the pressure drop across the CAJ holes. Under matrix conditions, no additional fracture or near-wellbore tortuosity friction is present, and any additional friction, such as friction in the annulus, is negligible compared with pipe friction and jet friction.

This article, written by JPT Technology Editor Chris Carpenter, contains highlights of paper SPE 157429, “Optimization of Limited-Entry Matrix Acid Stimulations With Laboratory Testing and Treatment Pressure Matching” by Mary S. Van Domelen, SPE, and Mohamad abd Hammoud, Maersk Oil Denmark; Gerard Glasbergen, SPE, Shell; and Noor Talib, SPE, Maersk Oil Qatar, prepared for the 2012 SPE International Production and Operations Conference and Exhibition, Doha, Qatar, 14–16 May. The paper has not been peer reviewed.