Nonmetallic (NM) downhole tubulars offer a longer lifetime than their steel counterparts while eliminating corrosion concerns and lowering total cost of ownership. Making them a reality, however, requires a rigorous ecosystem with multidisciplinary skill sets and technology expertise. The complete paper discusses the challenges that face the development of such tubulars starting from academia and research institutes to complement expertise and computer computational power and moving through to material suppliers and manufacturing facilities for pipe prototyping.

NM Pipe Construction and Technology Status

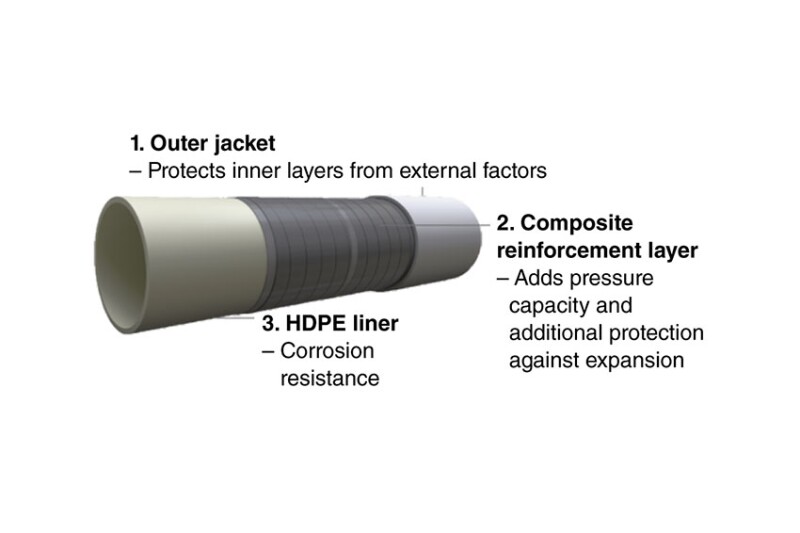

NM pipes also can include metallic elements, where a hybrid system of NM layers is incorporated into multilayered pipe structures that assume specific roles, similar to a metallic pressure armor layer in subsea flexible risers, jumpers, and flowlines. Another example is polymer-lined steel rigid pipes with glass-fiber reinforced epoxy (GRE), or a dual-layer thermoplastic-lined reinforced pipe (Fig.