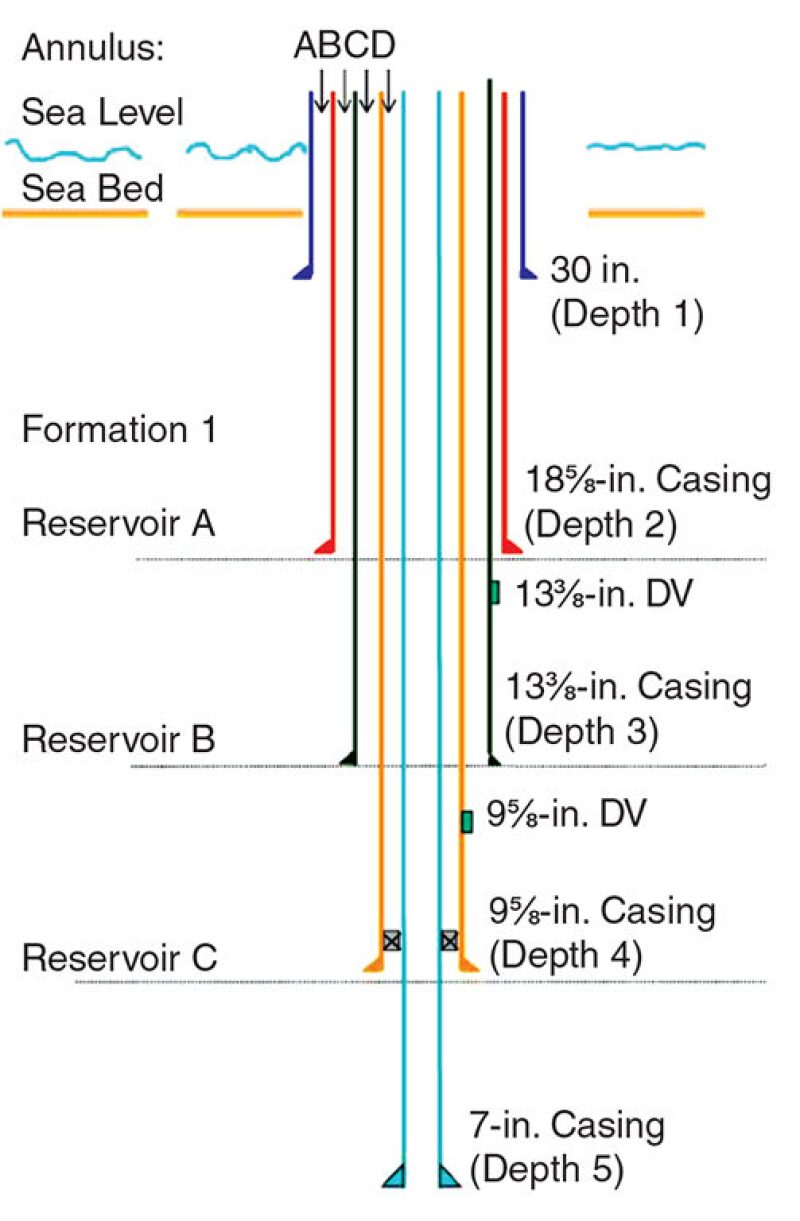

ADMA-OPCO had integrity problems in one of its gas wells, and abandonment was the only option available to restore the integrity of the offshore multiwell jacket and revive adjacent wells. Integrity problems included oil/gas bubbles observed on the seabed around the conductor pipe and high sustained pressures in the outer cemented casing annuli. Because the leak was determined to be located outside the casing, the perforation of several intervals was required. Some of the intervals were perforated through three casing strings, and the rest through four strings of casing, before being squeeze cemented.

Background

The example well, designed as a 7-in.-monobore gas-production well (see Fig. 1), was due for abandonment. The surface leaks in the different casing annuli had to be resolved before proper abandonment could occur. It was clear from the prejob analysis that cement-squeezing operations would be required at different depths through three and four casing annuli. Techniques for exposing these annuli for remediation included underreaming with a milling tool, abrasive jetting, and perforating. Underreaming would have been a very costly operation, and abrasive jetting is not reliable to penetrate through more than one casing string; therefore, perforating was chosen as the method for accessing the required annulus.

Perforating through four strings of casing is not typical, and many questions were raised concerning the reliability of this technique and how its effectiveness would be measured. With the need to access up to four different annuli, conventional circulation and pressure-testing techniques could not confirm that all casings had been penetrated. Modeling and testing were performed to improve confidence in this technique.

Perforating Gun and Charge Selection

Modeling. A 4½-in. gun was selected for carrying a premium deep-penetration charge in the 7-in. liner. Two charge options were available for this: a 5-shots/ft (spf) 72°-phase version carrying 38.8‑g HMX (a nitroamine high explosive) perforation charges and a 12-spf 45°-phase version carrying 22-g HMX charges. The model was set up with the casing and other well parameters and run with various perforation-charge/gun combinations.

The modeling results show that all charges in all phases will penetrate the four casing sizes; however, the outermost-casing entry-hole size with the 12‑spf gun is very small, ranging from 0.16 to 0.09 in.

Laboratory Testing. There was concern over the modeling results because the casing entry-hole prediction is not considered accurate beyond two casing strings; therefore, to improve confidence in the results, a series of tests was conducted in the laboratory. The laboratory tests were set up to simulate offset casing, and each phase of the perforating gun was tested with the same types of charges that would be used in the field.

For the 5-spf 72°-phase perforating gun, shots were made at 0, 72, and 144° phases; for the 12-spf 45°-phase gun, shots were made at 0, 45, 90 135, and 180° phases. Single shots were made in the desired phase directions.

The results confirmed the necessity for performing the physical testing to verify the charge performance under these actual field conditions. The 12-spf gun is unsuitable because it does not penetrate through the outer casing in the 180°-phase shot, and the entry-hole sizes for the other phases are unacceptable.

The 5-spf results were more encouraging but also show considerable deviation from the model results in the 9⅝- and 13⅜-in. casings.

The discrepancies between the model and laboratory-test results are not unexpected. At the moment, the three- and four-casing-string entrance-hole prediction in the model is based on extrapolation techniques only. This will be updated in the model once more tests are completed.

On the basis of these results, the 5-spf 72°-phase gun with the 38.8-g HMX charge was chosen for this job.

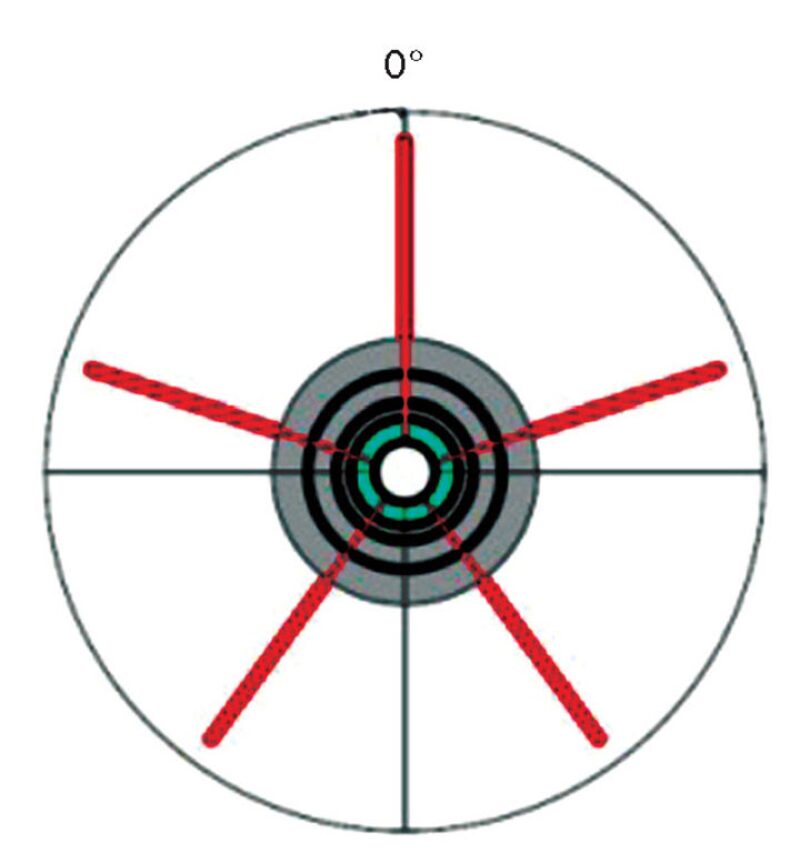

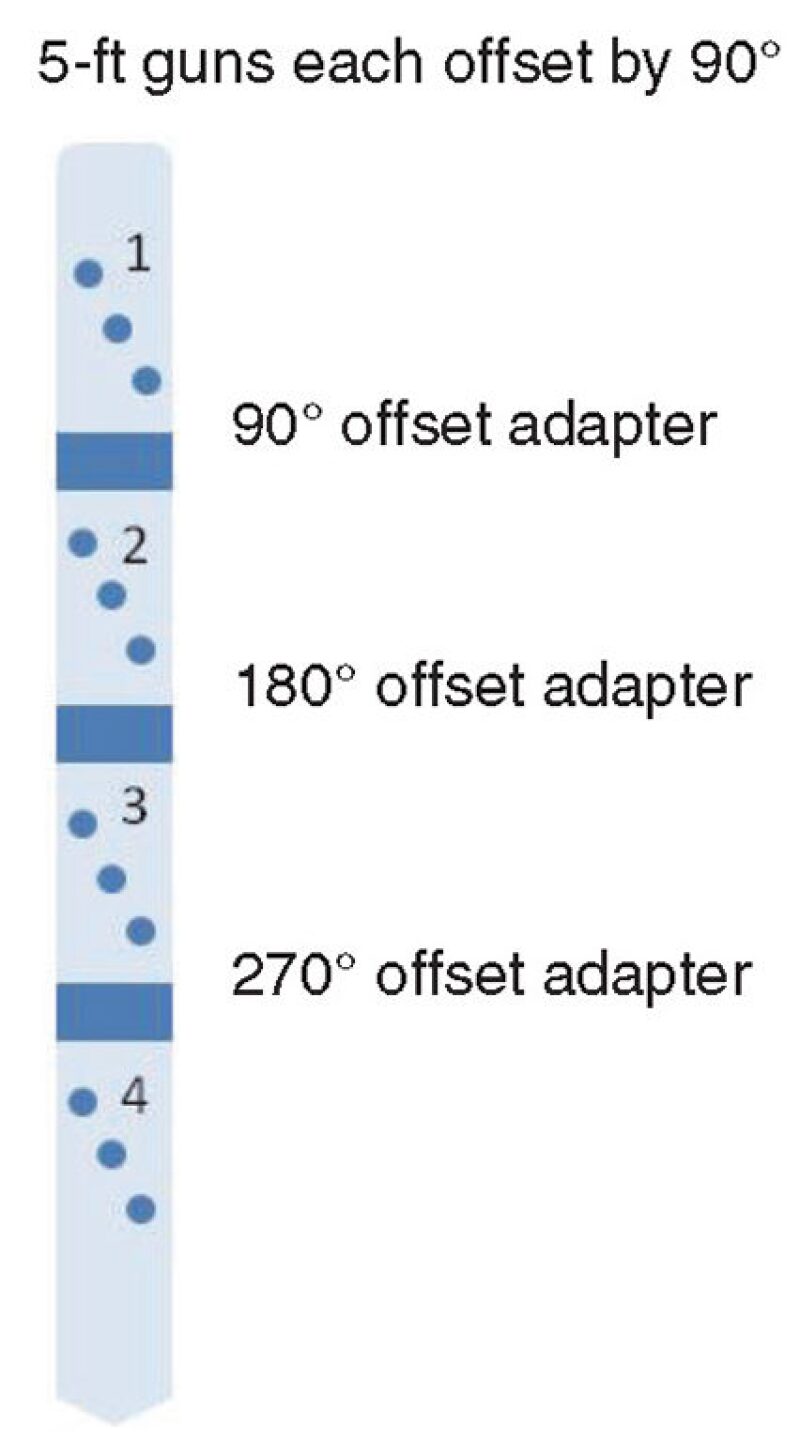

Gun Phasing. The requirement for the most-powerful deep-penetrating perforating charge to be run meant that the phasing had to be a compromise. The 5-spf gun is available in only the 72° phase, as indicated in Fig. 2. A gun system could have been developed with some engineering modifications, but time and financial constraints prevented this. To improve the effective phasing of the gun system and increase the possibility that all channels would be accessed, special orienting adapters were used. These adapters have locking keys that allow for a 90° offset between the perforating guns. The perforating intervals were 20 ft in length, so with four 5-ft-long perforating guns three of the orienting adapters could be run. This would then offset the phase between the guns by an effective phasing of 18°. A side view of the assembled gun with the adapters is shown in Fig. 3.

Job Execution

Several zones were selected to be perforated and squeezed: two zones with three casing strings and two zones with four casing strings. The guns were loaded in the onshore gun shop and shipped to the rig, where they were assembled at the wellsite as four 5-ft gun assemblies. Because of local regulations requiring pipe in the well at the time of perforating operations, these guns were run on drillpipe with a tubing-conveyed-perforating pressure-actuated firing head and were shot in overbalanced conditions.

To further improve the chances of reaching all of the leak paths behind the pipe, each zone was perforated twice, making the final shot density 10 spf in the perforated interval. There was no attempt made to alter the phasing of each run; thus, the relative shot phasing for each run was random and was likely to be different from that of the initial run, further improving the chances of a successful squeeze job.

Special fine cement designed for cement-squeeze operations addressing small channels was pumped at an acceptable rate into the perforations and then allowed to set.

The first perforating operation was though three casing strings in which two zones were shot 30 ft apart to allow for a circulation squeeze. Once the second gun was removed from the well, a cement-squeeze pipe string with packer was run and a circulation squeeze and block squeeze were executed. This operation was repeated until the zone exhibited a good pressure test.

The second and third perforating operations were through four casing strings, and a block squeeze was carried out. After the cement was set, a pressure test was performed in the squeezed-off intervals, which often showed an incomplete squeeze. Consequently, more cement was pumped to squeeze the remaining channels. This operation was repeated until the interval showed a good pressure test, confirming that the zone was sealed.

Results

Care was taken to completely seal off each of the four zones that were squeezed. While it was not possible to determine the cement placement with respect to the different annuli, an assumption was made that the special squeeze-type cement together with the multisqueeze method would place cement into the channels where gas was leaking and would seal them.

The annulus pressure was monitored during the operations and continued to be monitored after the job. The pressure was monitored for a period of 3 months after the job was completed. The results prove that the abandonment job was successful and that the objectives were achieved.

This article, written by JPT Technology Editor Chris Carpenter, contains highlights of paper SPE 166729, “Perforating for Squeeze Through Four Casing Strings To Remediate Annulus Gas-Leak Problem,” by Mohamed El-Sayed Ibrahim, SPE, Ahmed Khalifa Al-Neaimi, SPE, Mohamed Abdelsalam Hassane, SPE, Abdul Salam Mohamed Al-Mansoori, SPE, Shanof Mohamed, SPE, and Omar Al-Mutwali, SPE, ADMA-OPCO, and Alan Salsman, SPE, Schlumberger, prepared for the 2013 SPE/IADC Middle East Drilling Technology Conference and Exhibition, Dubai, UAE, 7–9 October. The paper has not been peer reviewed.